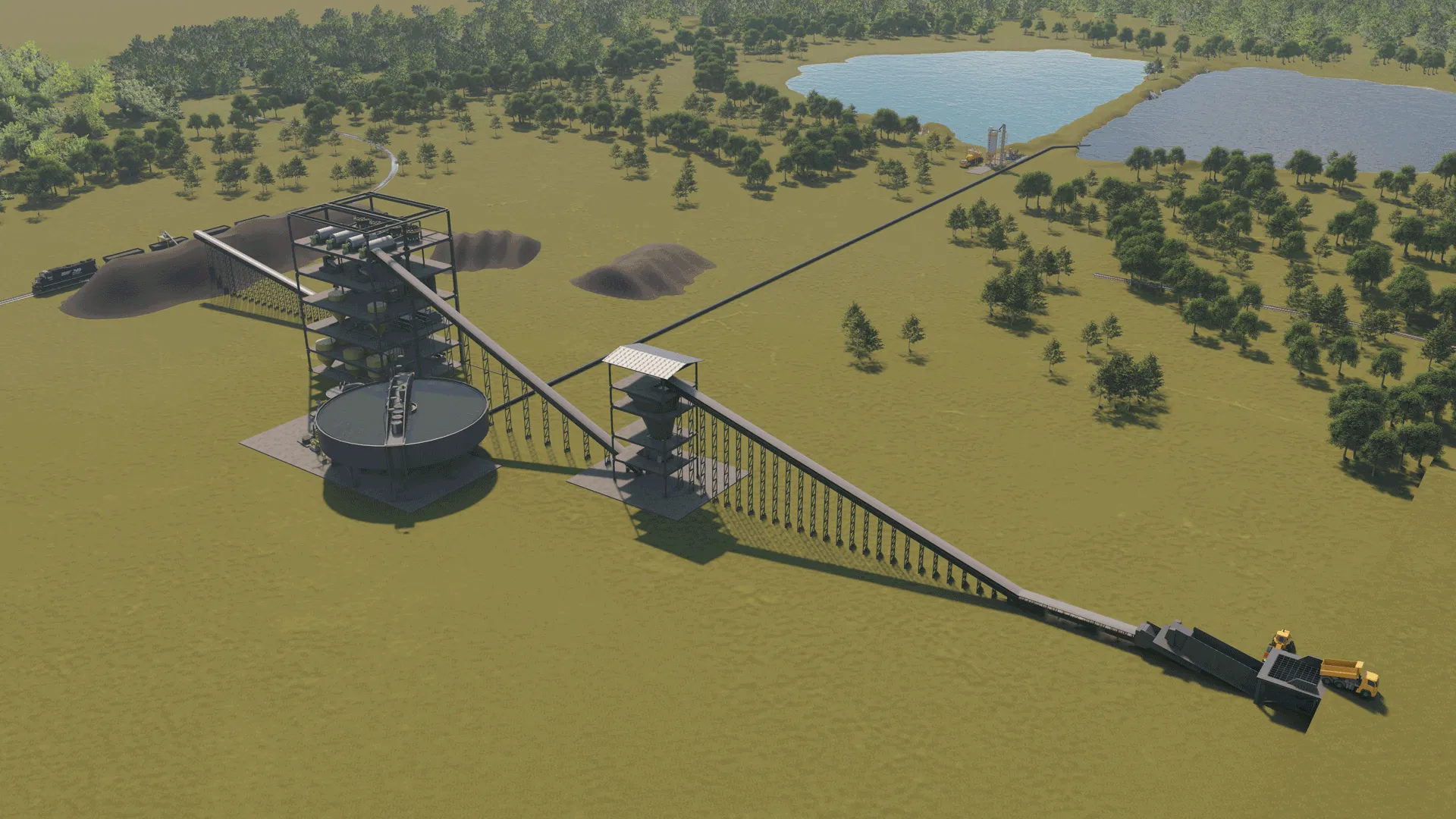

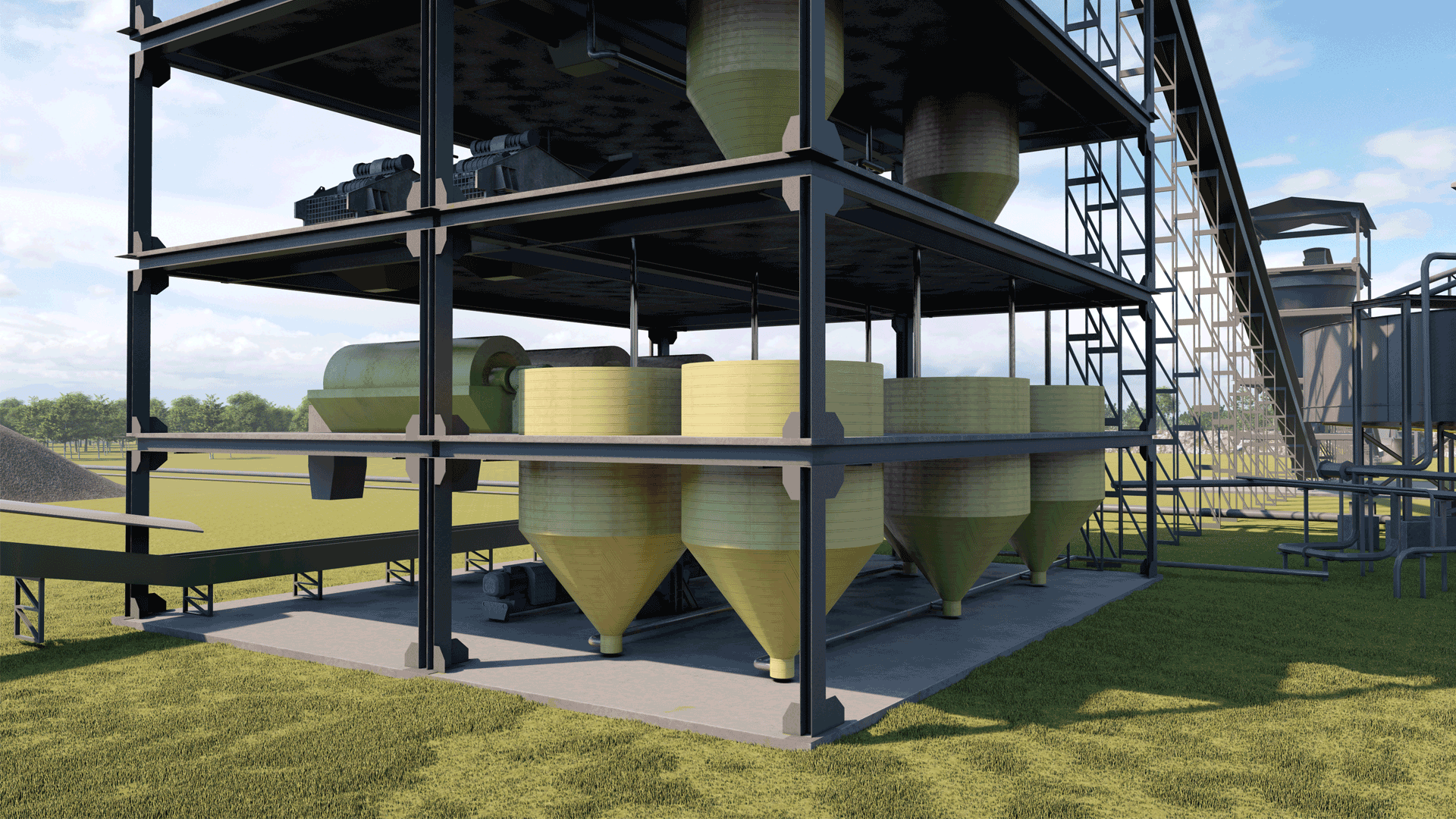

Coal Mining Industry Solutions

Sizing & Screening

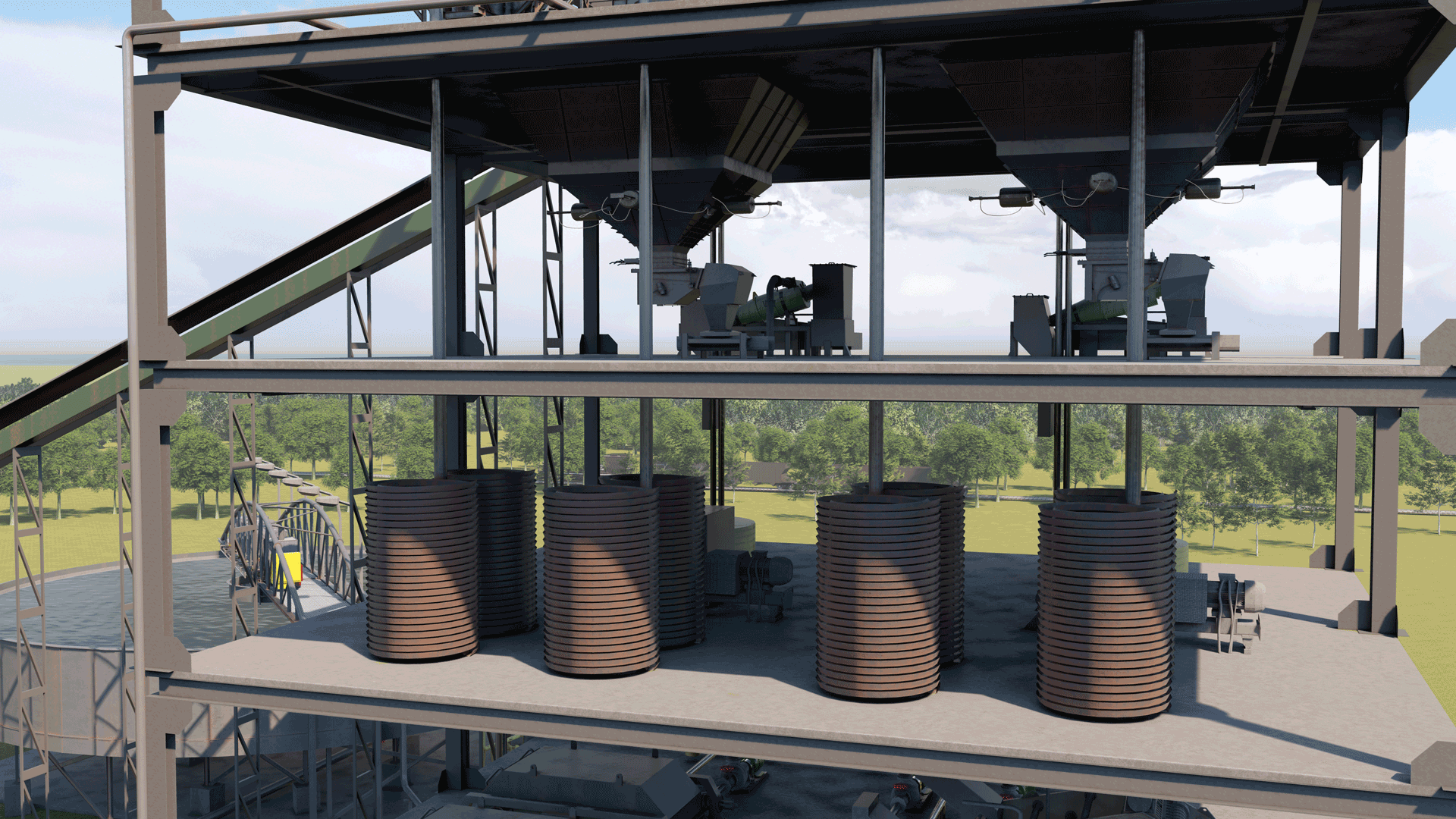

Density Separation

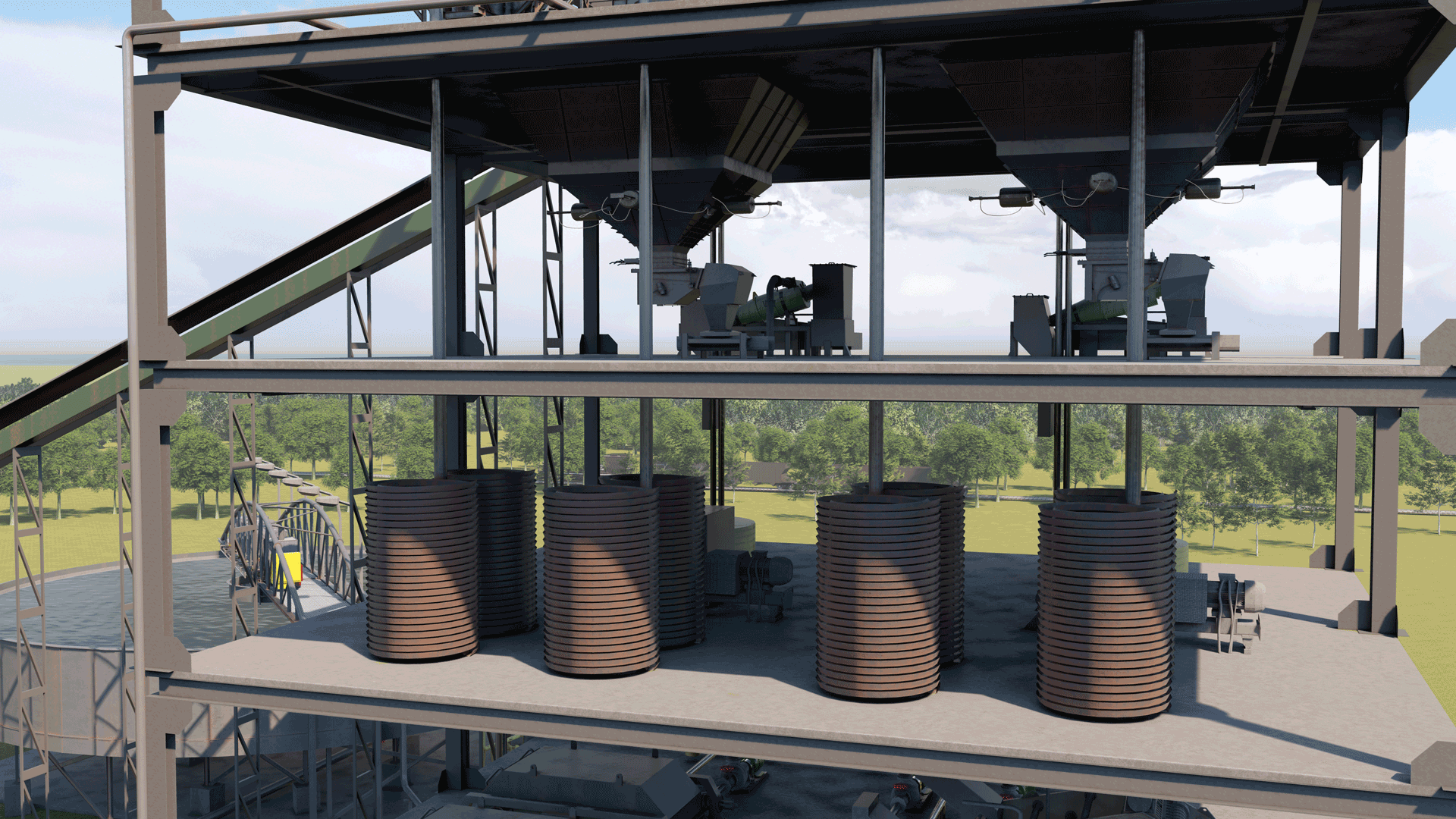

Dewatering

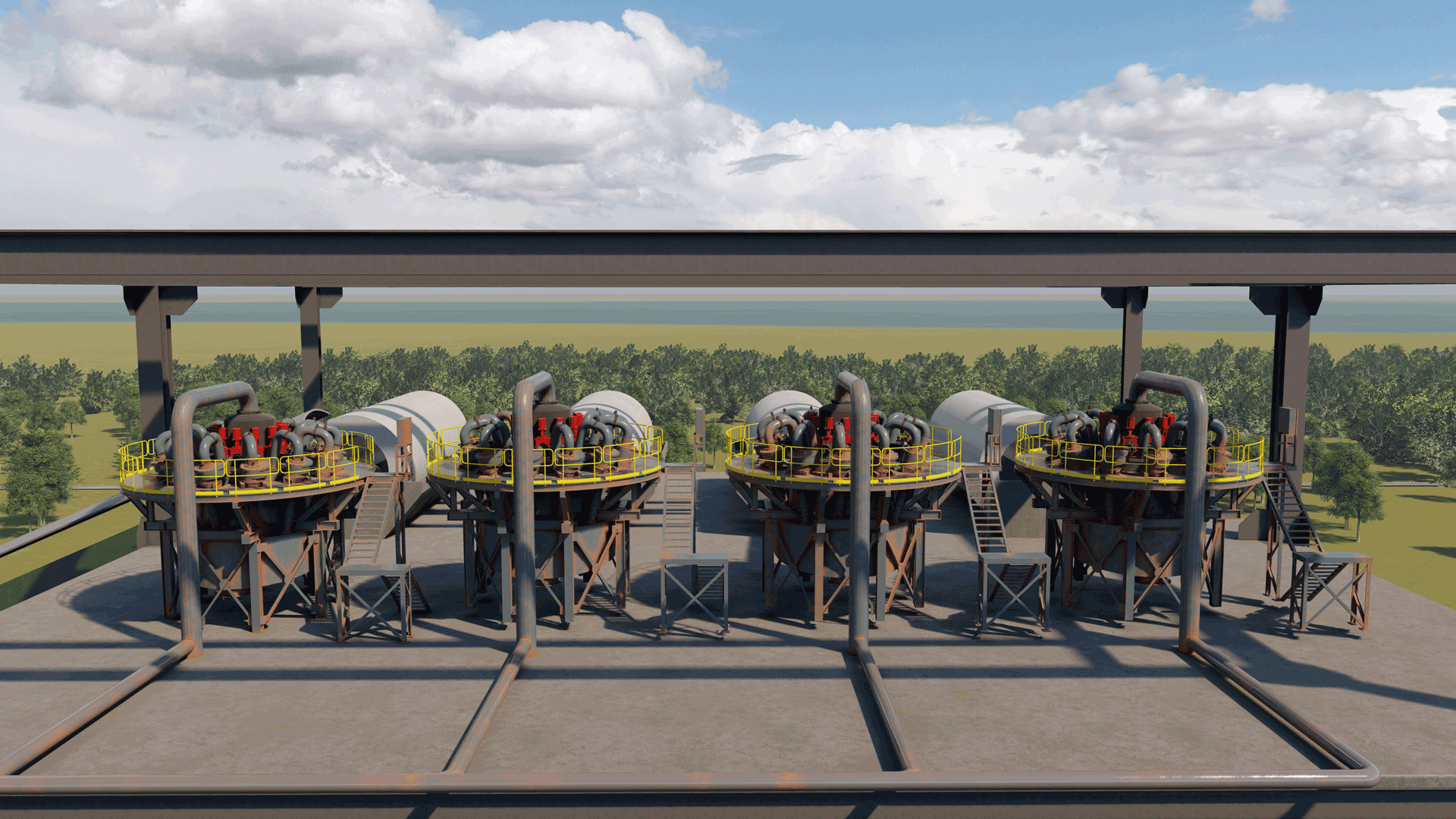

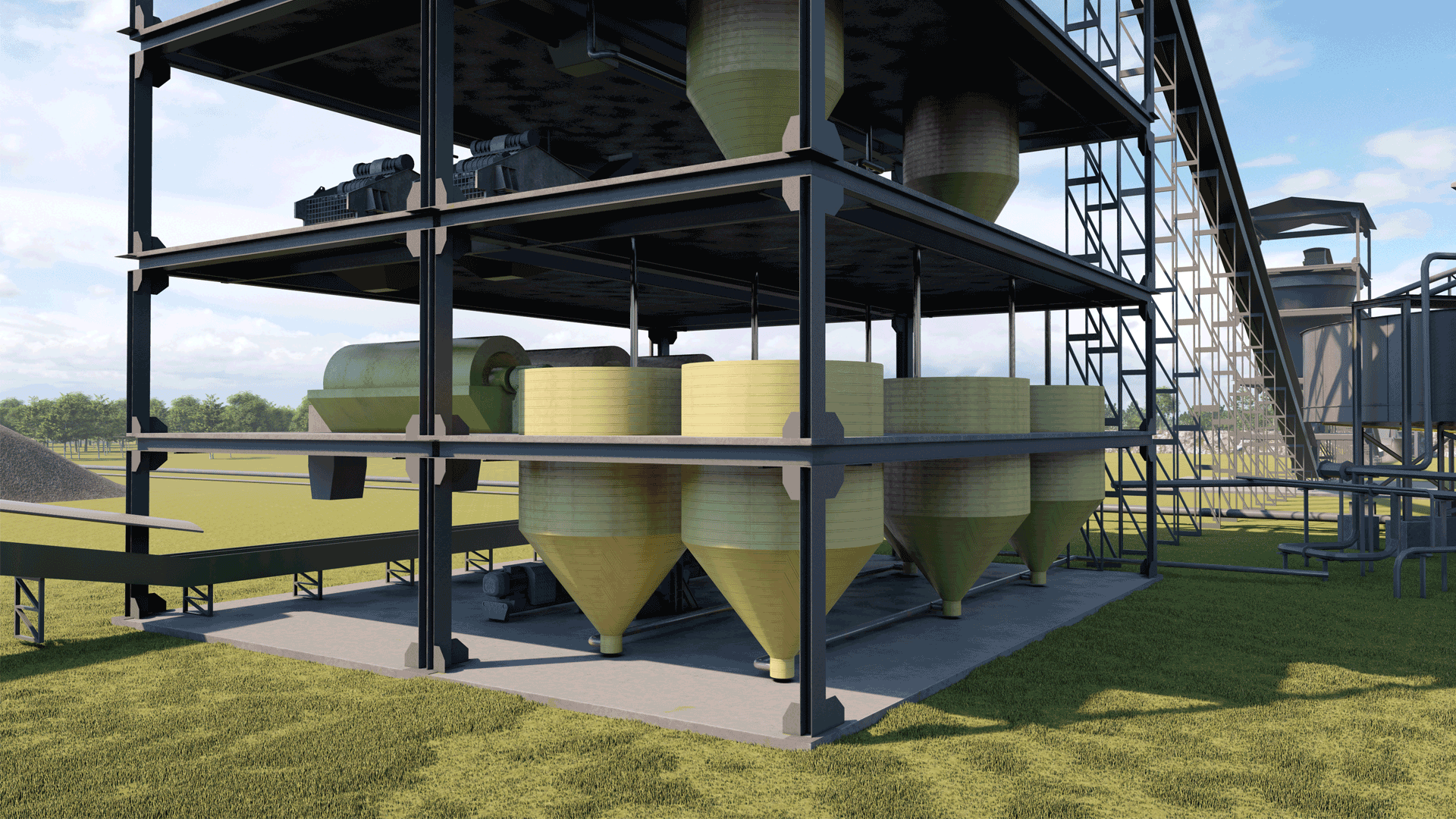

Classification & Desliming Cyclones

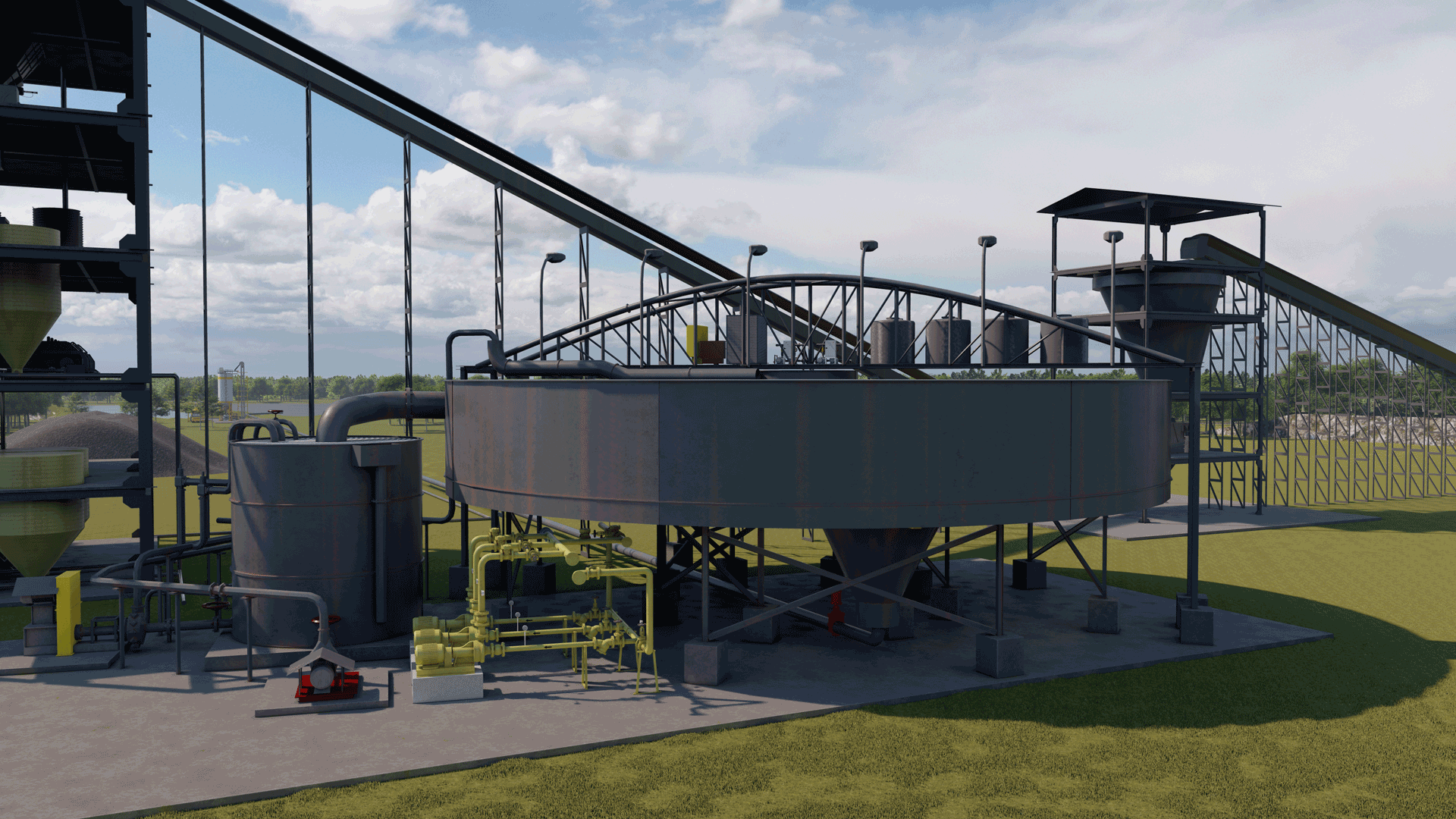

Clarifying & Thickener

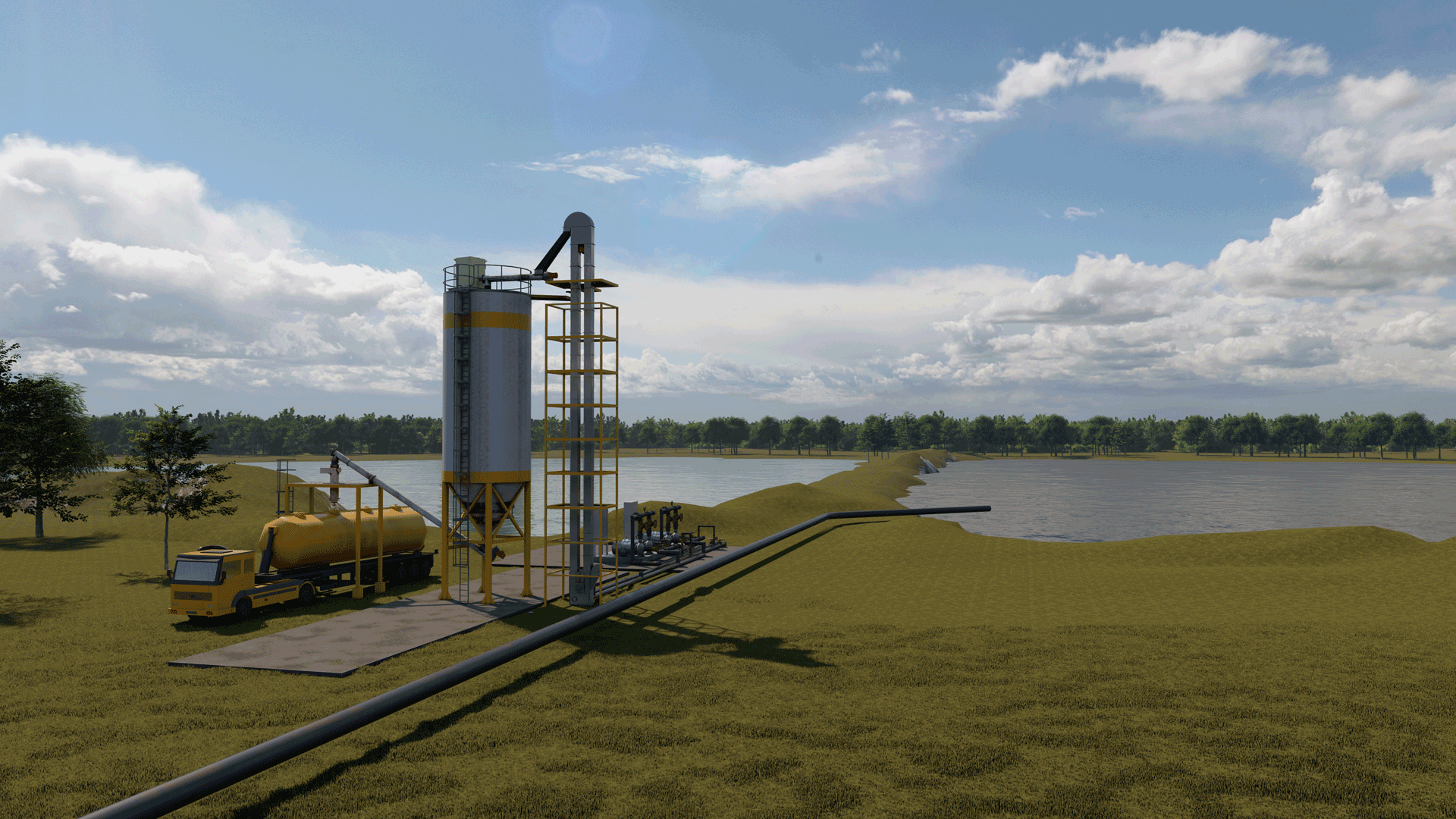

Tailings, Supply Tank & Dam Pump Station

Sumps & Pumps

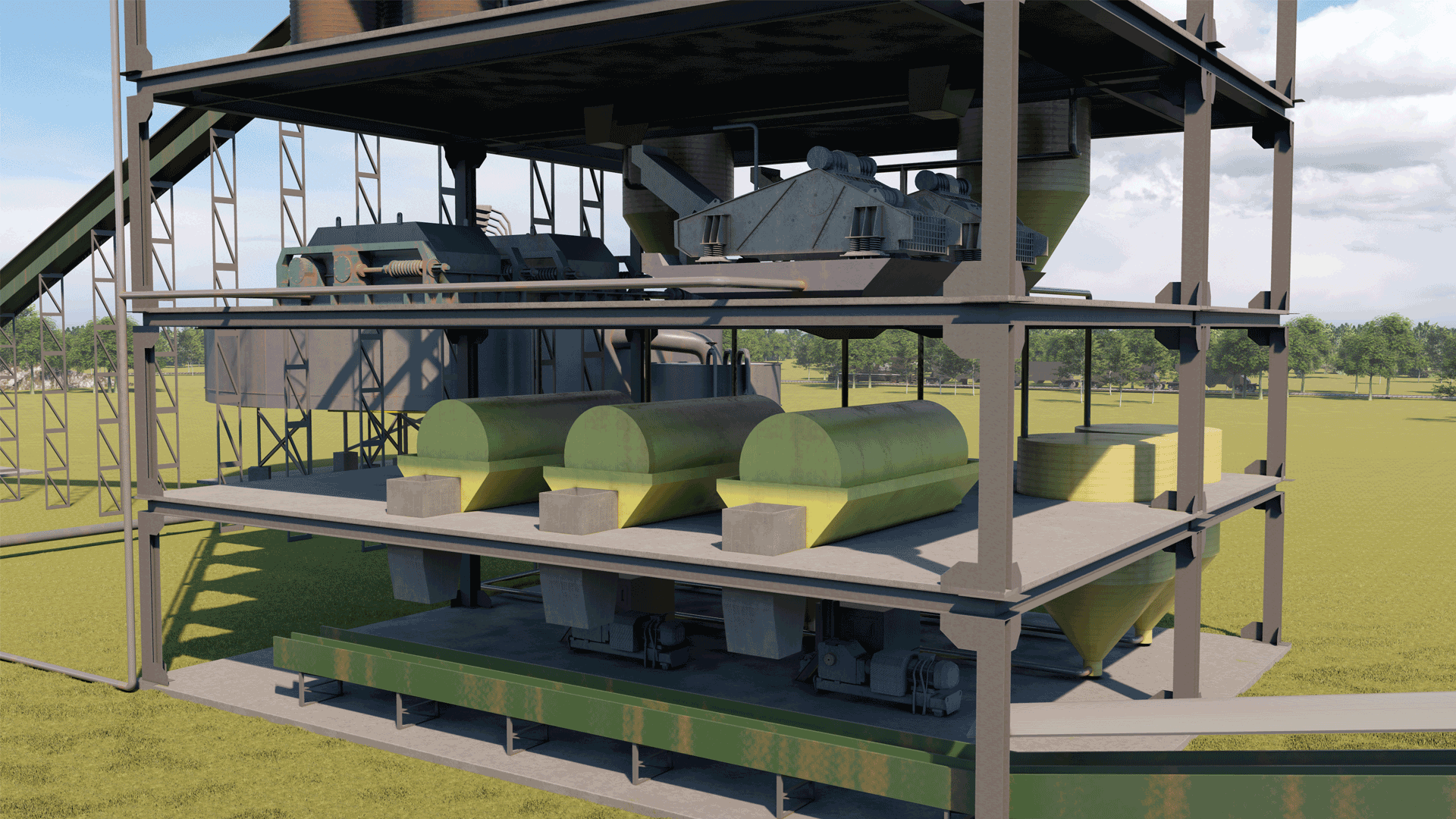

Sizing & Screening

Screening is used to separate different sized coal, while coarse and fine coal are separated. As this occurs, the coal is washed.

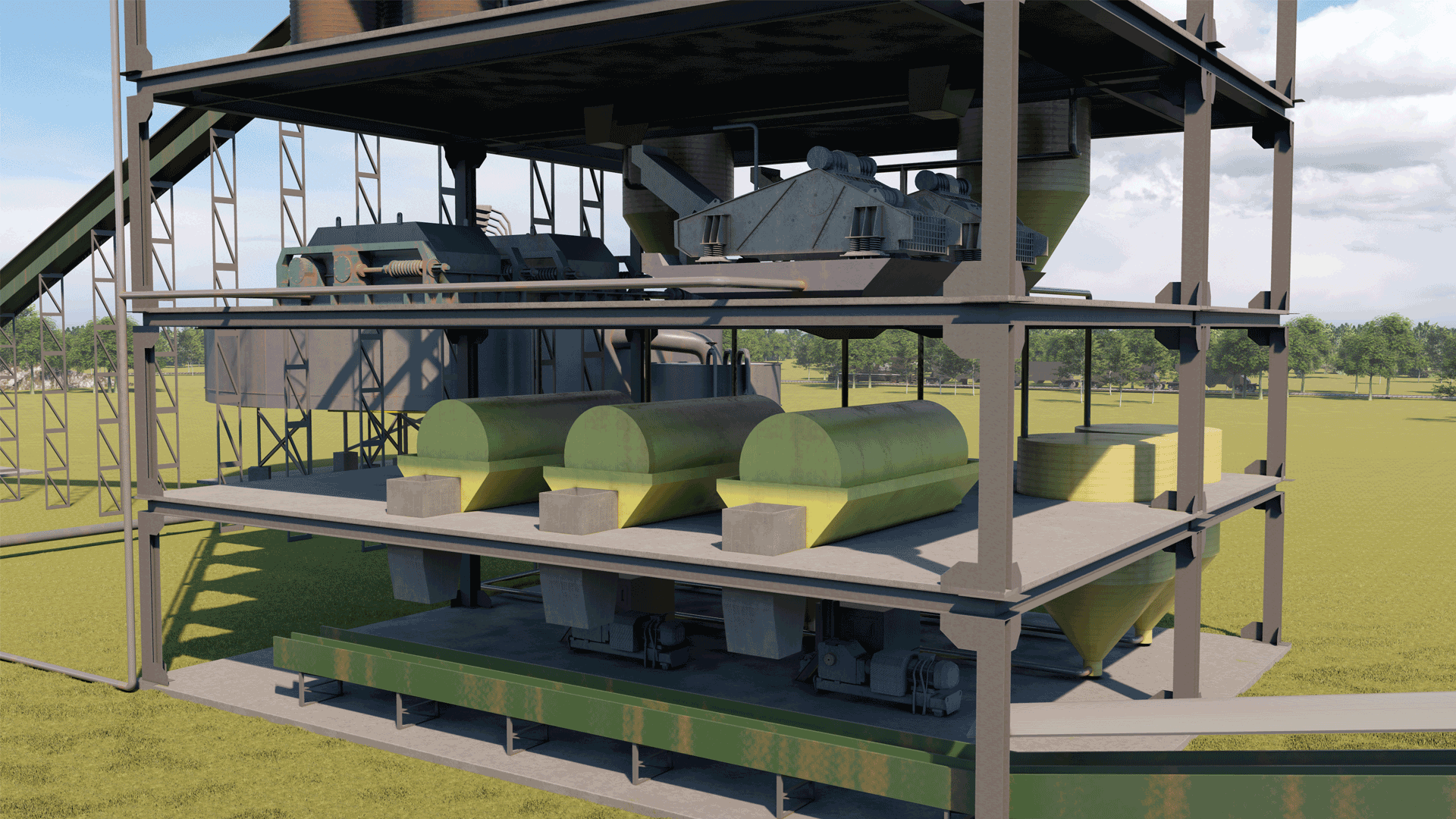

Density Separation

When water is added, particles sink to various depths depending on their densities. The various components can then be separated.

Dewatering

After coal is cleaned, the unwanted water must be removed from the particles using mechanical dewatering equipment.

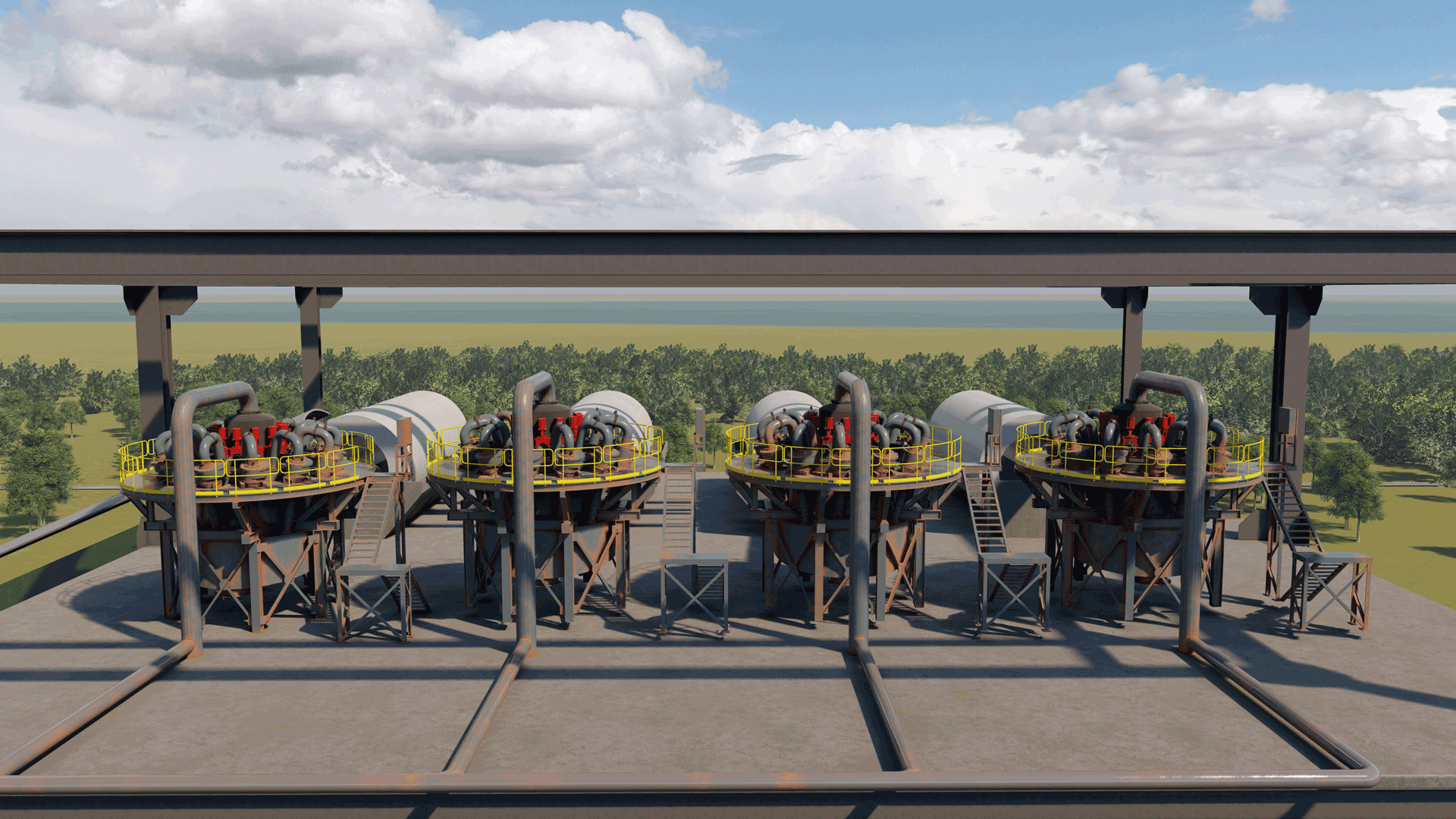

Classification & Desliming Cyclones

Used for separating coal and slurry based on particle weight. Rejects pass through the underflow and clean coal passes through overflow.

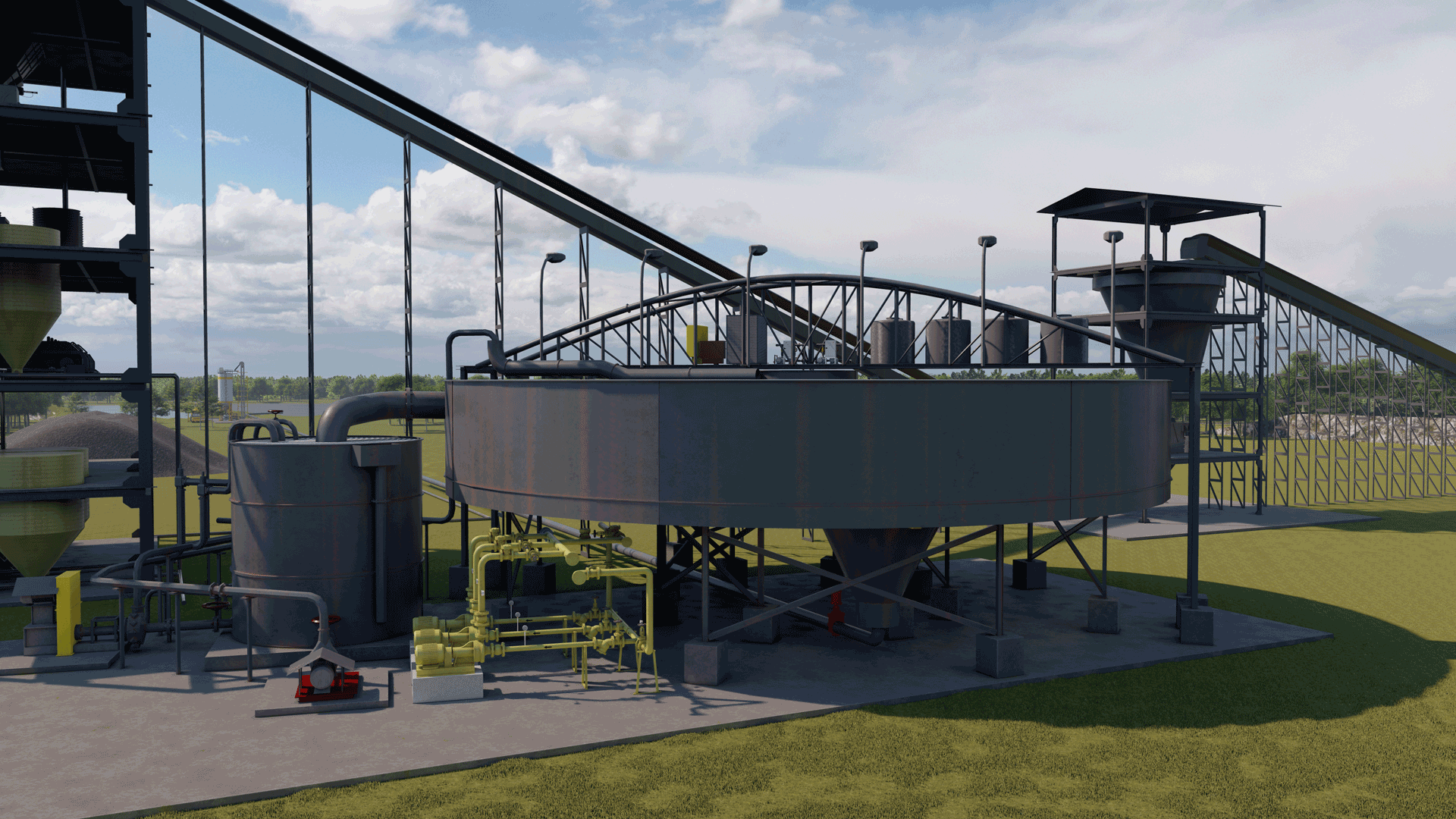

Clarifying & Thickener

These are used to settle solids and return clarified water back to the process. The tailings are pumped to dams for futher settling.

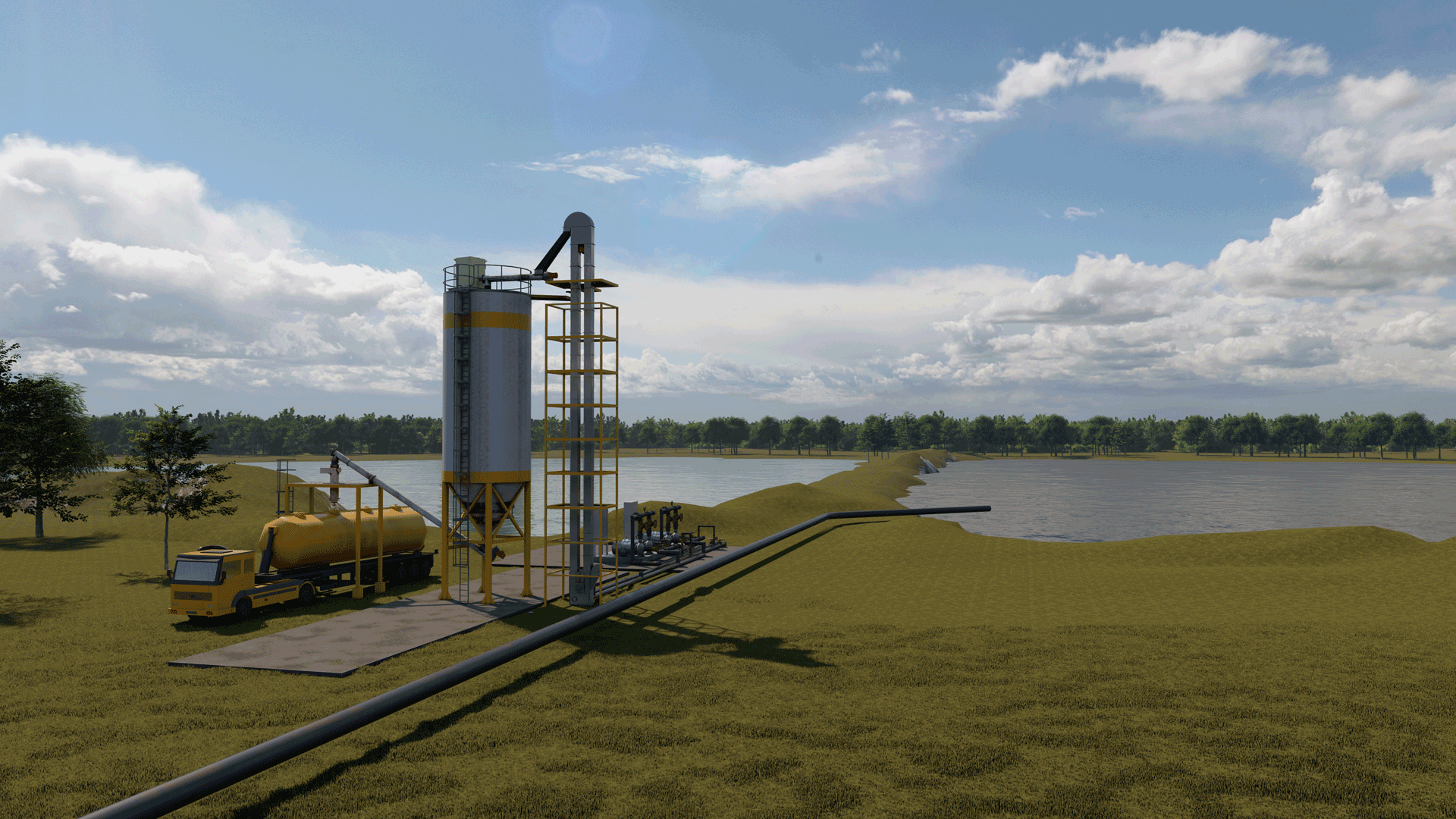

Tailings, Supply Tank & Dam Pump Station

Ponds are used to store by-products of the process. Tailings slurry can settles on floor while the water can be reclaimed.

Sumps & Pumps

Sumps collect the process liquids. A sump can also be used to manage surface runoff water. Pump are used for transporting the media.

-copy.webp?sfvrsn=d2f79d13_1)

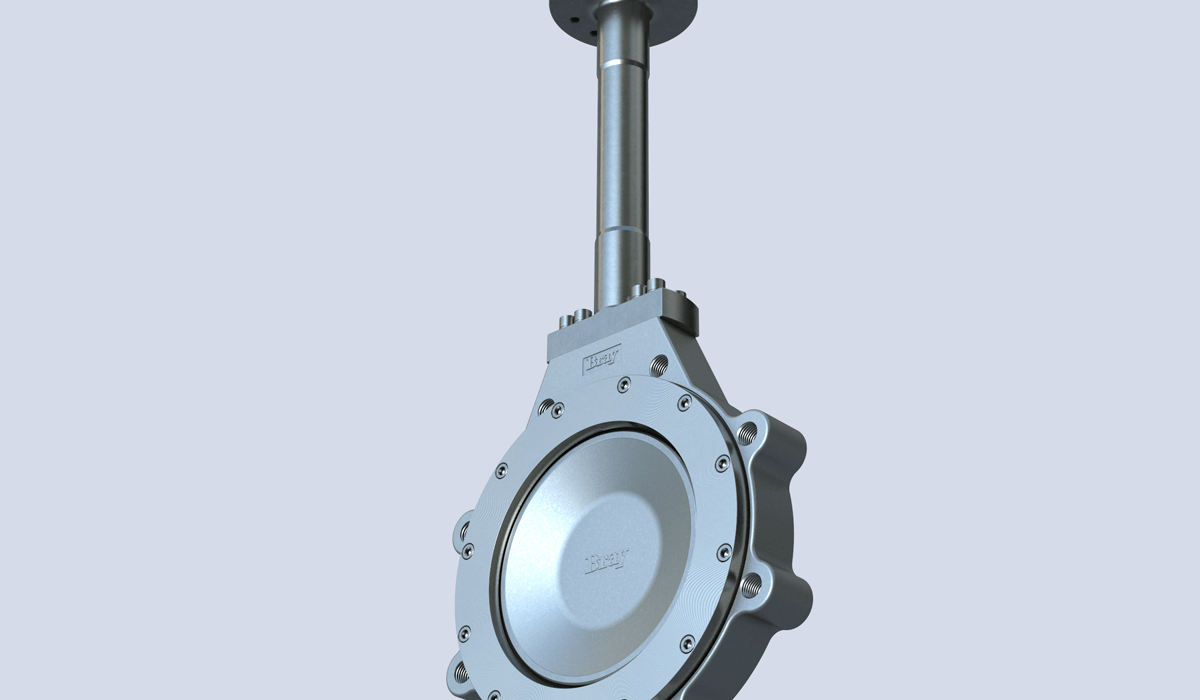

Ceramic Lined Control Valve Greatly Improves Performance in Copper Concentrator Process

b4d31b93-733c-443d-9d76-c16b42fbc555.webp?sfvrsn=ca64f077_1)

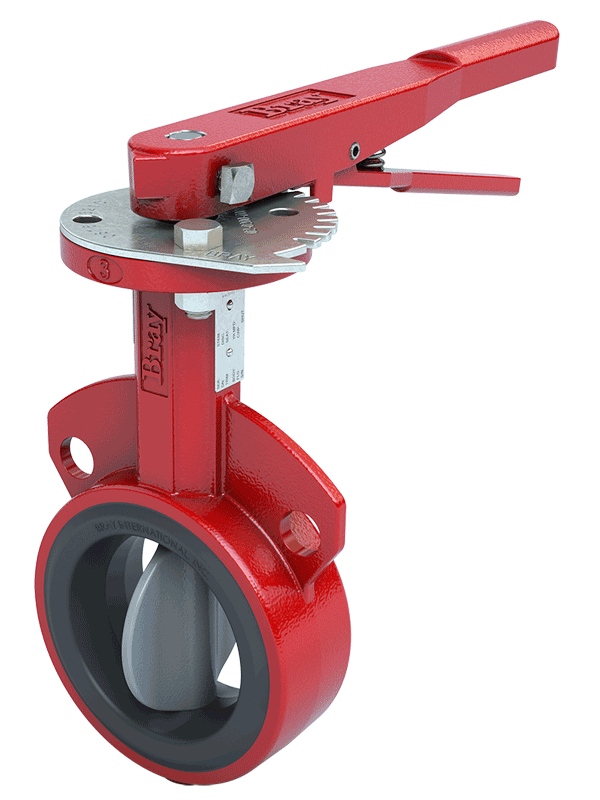

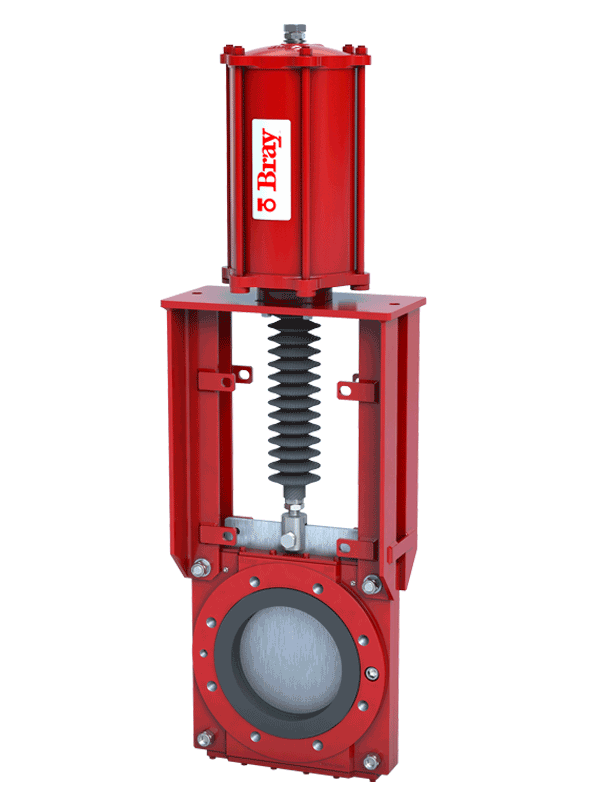

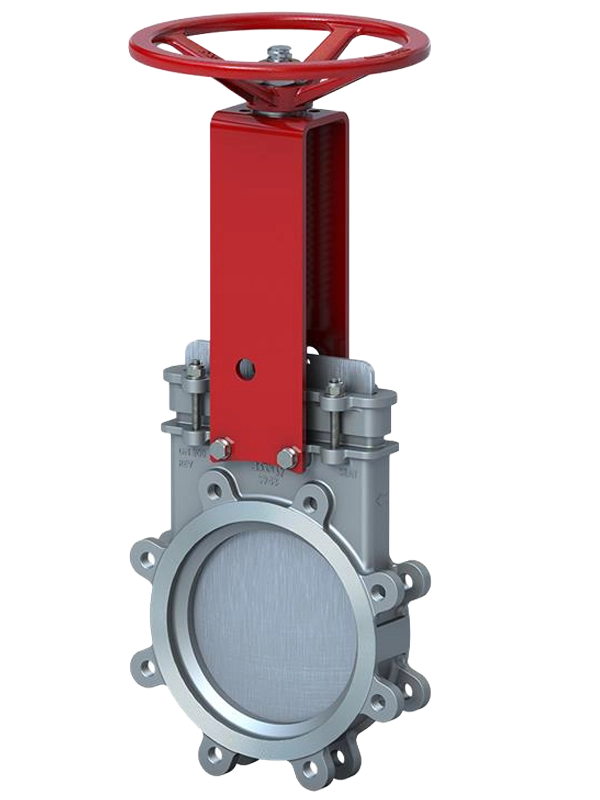

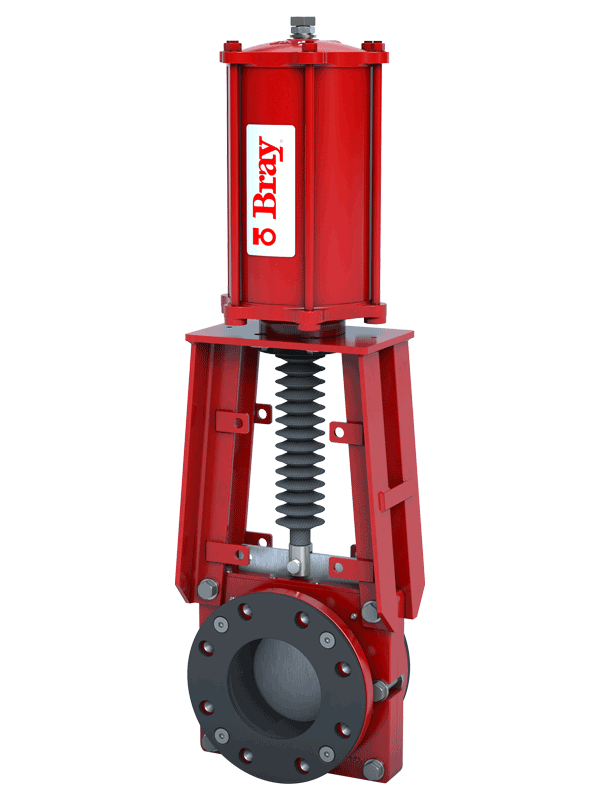

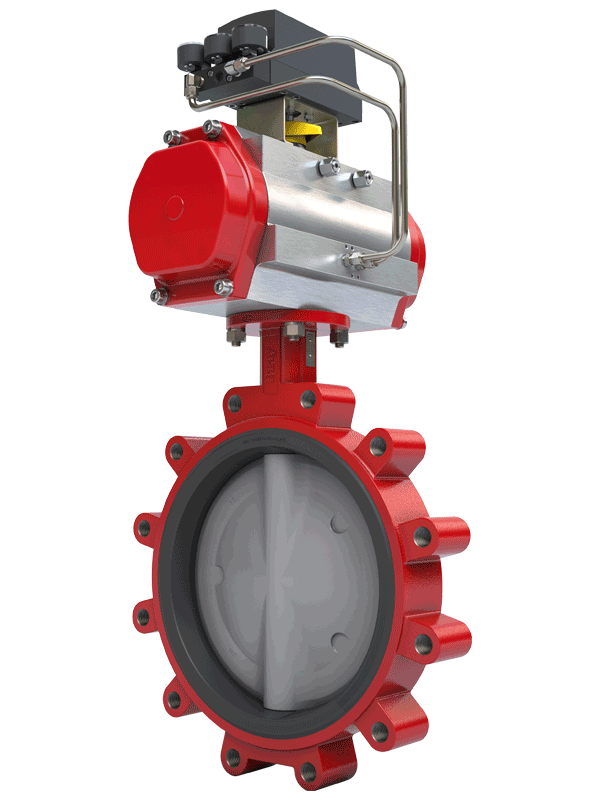

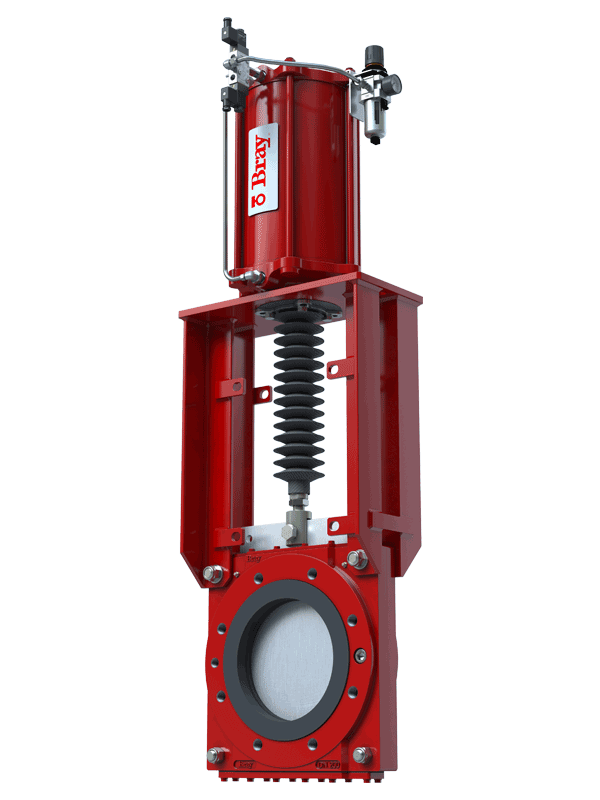

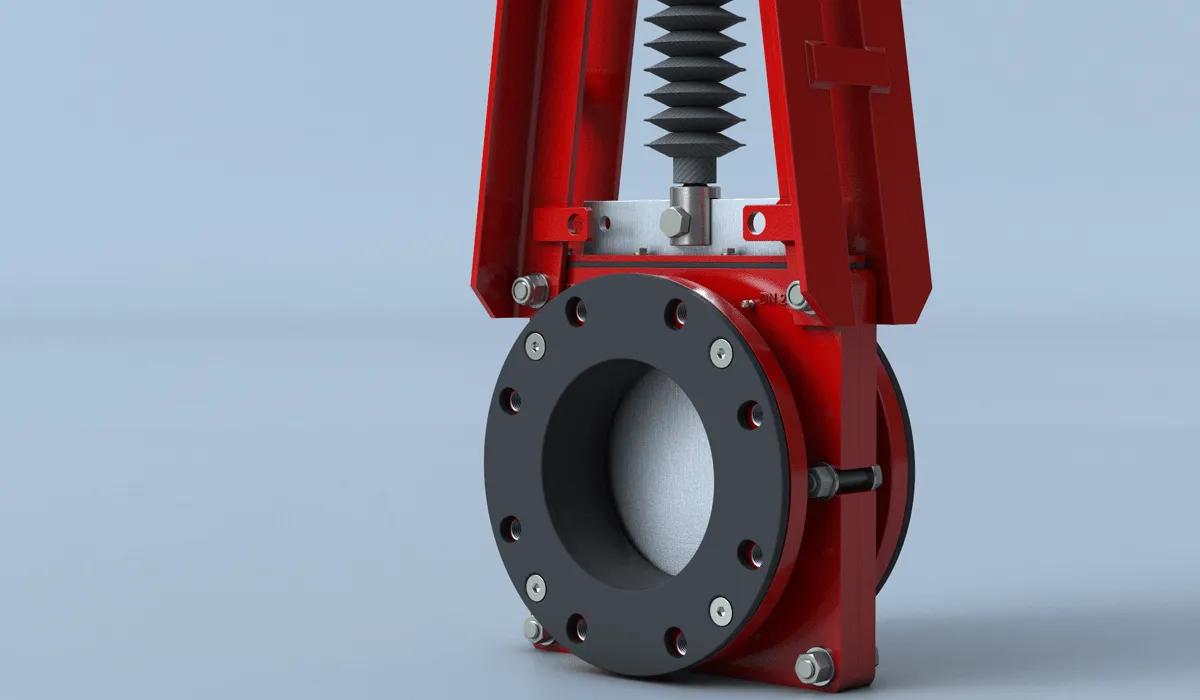

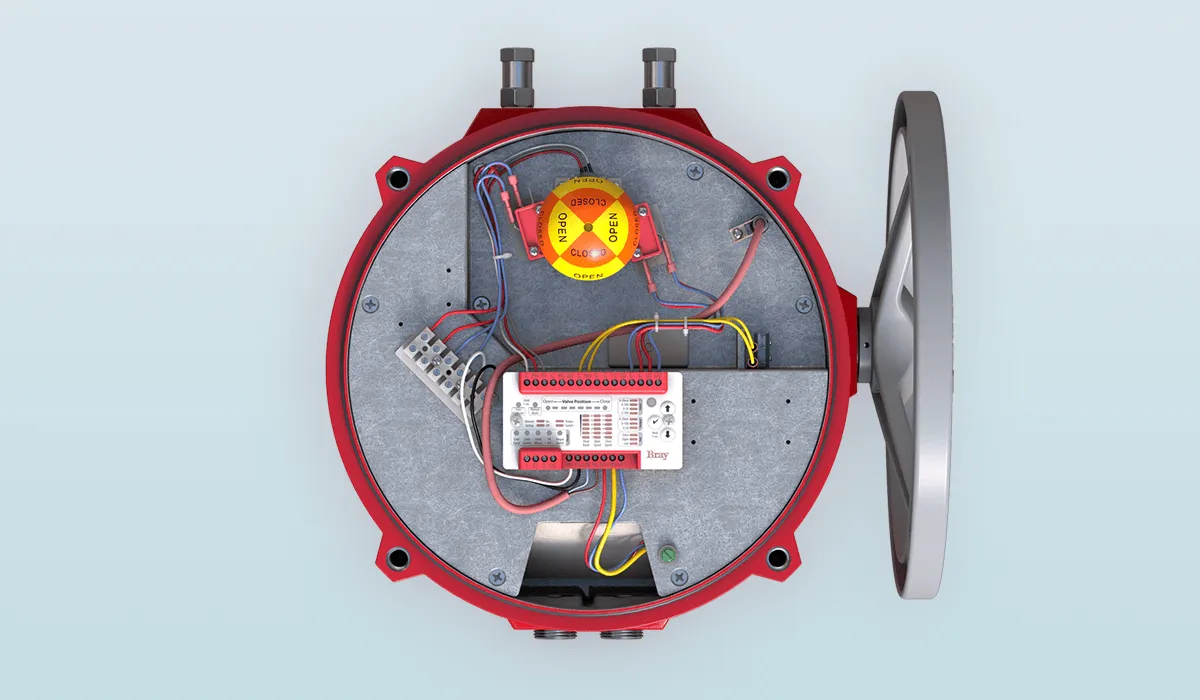

Knife Gate Valves Greatly Improve Productivity in Coal Mining Cyclone Application

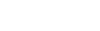

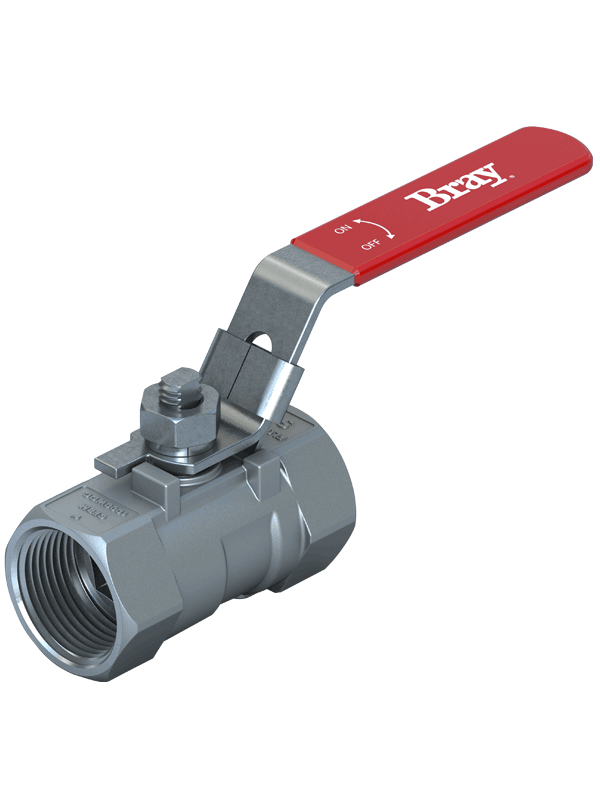

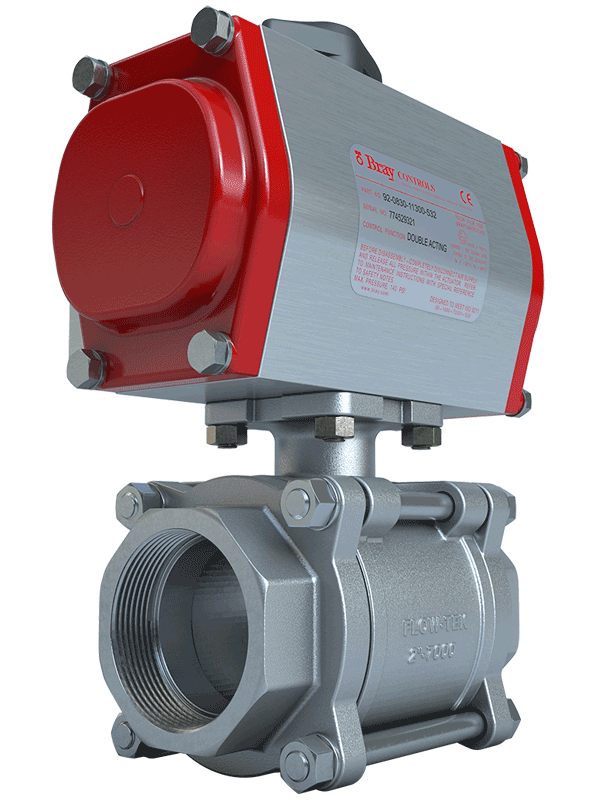

M1 Severe Service Ball Valve Extends Service Life 4 Years in HPAL Autoclave Isolation