Keeping Our Air Clean

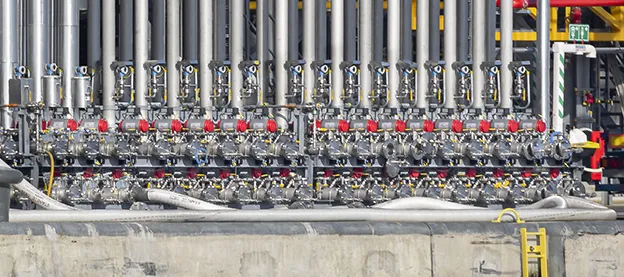

Fugitive Emissions

Bray is committed to helping our Oil & Gas industry customers tighten their grip on fugitive emissions, protect workers, the environment and your company’s bottom line. Our industry leading range of innovative low-emission valves are engineered and certified to meet or exceed emissions standards including API 608, API 609, 641, ISO 15848-1 and TA LUFT. Our continued research and testing at Bray's Fugitive Emissions testing facilities in Houston, India and China ensure continued compliance and development of reliable, innovative new products certified to comply with evolving global fugitive emissions standards such as EPA Method 21 and EPA guidelines for Leak Detection and Repair (LDAR to identify unintended fugitive emissions from equipment in an oil and gas.

Bray Solutions for

Upstream Oil & Gas

Bray manufactures a wide range of rugged and reliable valves, actuators, positioners and other innovative technologies for upstream oil and gas applications including exploration, drilling, separation, dehydration, and compressions. Bray also engineers innovative custom engineered solutions for severe service applications for high pressure pipeline, onshore, Oil Sands, gas collection and remote location flow control as well as offshore jack up rigs, Floating Production Platform and Storage from deep water reserves.

Bray Solutions for

Midstream Oil & Gas

From field separation and gathering through treatment and transmission, Midstream Oil & Gas operators manage the infrastructure that moves oil & gas from the field to the refinery and power plant. Bray can help your company maximize uptime and profitability and minimize downtime with our comprehensive range of reliable Trunnion Mounted Ball Valves (TMBV), Triple Offset Butterfly Valves (TOV), Pneumatic, Hydraulic and Electric Actuators, Controls, and Control Accessories.

Bray Solutions for

Downstream Oil & Gas

Bray manufactures a complete line of high-quality valves, actuators, and accessories, designed for the harsh conditions found in downstream oil & gas storage tanks and refineries, that convert raw hydrocarbons into gasoline, jet fuel, fuel oils, benzene, plastics, and other useful products; as well as LNG drying, pumping stations, liquefaction, and gasification. Explore our complete range of Control Valves, Floating Ball Valves, Trunnion Mounted Ball Valves and Triple offset Valves, for refining and gas processing applications.

Tanks & Terminals

Bray's comprehensive line of valves, actuators and accessories are engineered, and field proven to provide reliable service in demanding Tank and Terminal applications.

Certified and Trusted

By thousands of companies worldwide

Bray valves for the Oil & Gas industry are performance tested and certified to conform to API 6D, API 594, API 598, API 607 and API 608. Other certifications or compliances include ABS, API 641, ANSI FCI 70-2, ATEX 2014/34/EU, Bureau Veritas, Canadian CRN, CCS, DNV, GOST-R, Lloyd's Register, IEC 61508 SIL 3, ISO 10497, ISO 15848, NACE MR0175, PED 2014/68/EU, PE(S)R, UL, UKEX, Ukraine TR and more.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business