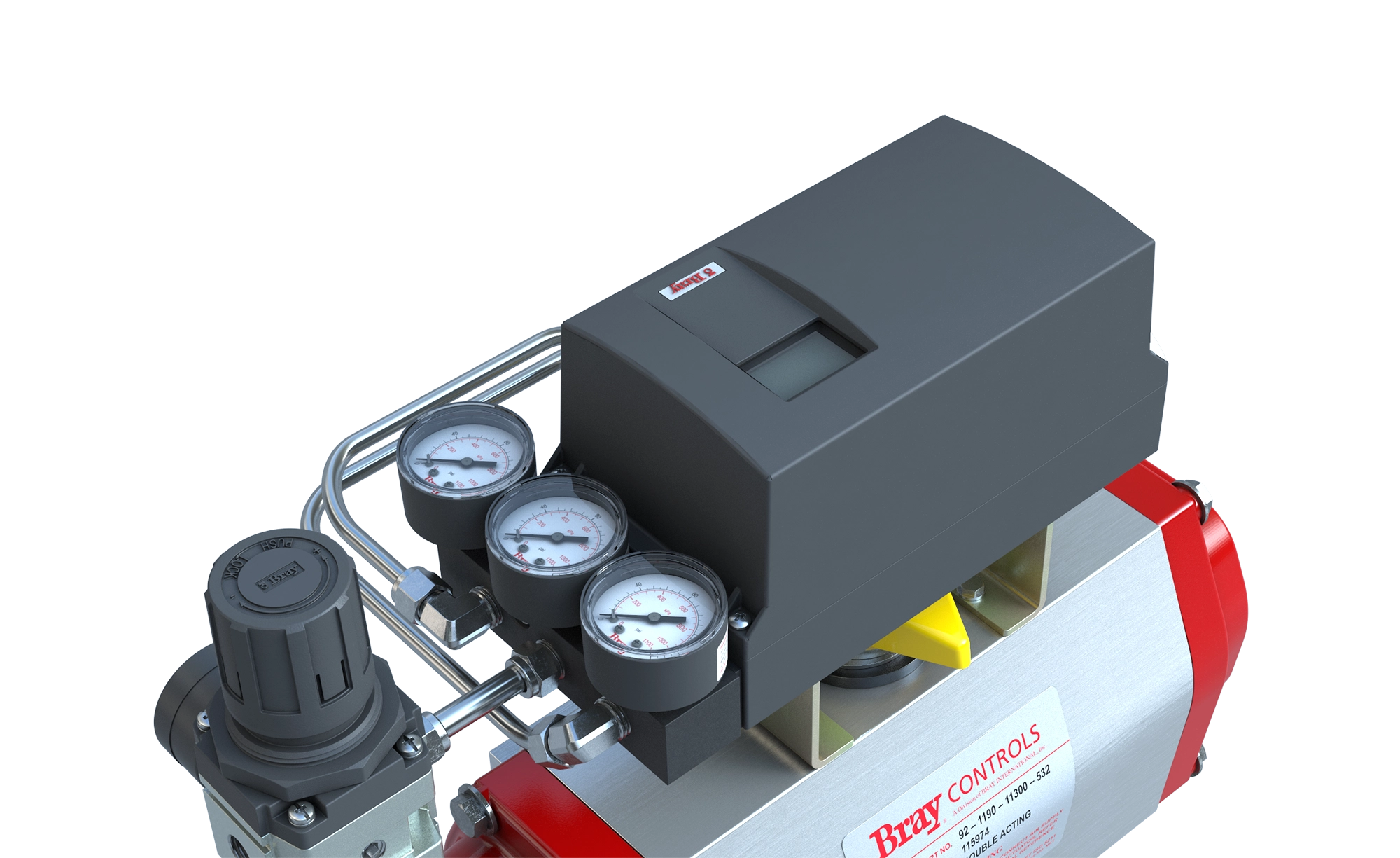

Electro-Pneumatic Positioners

Precision digital control with proven reliability Bray’s Series 6A positioners were designed with ease of installation, simple calibration, efficiency and economy in mind. Units for rotary single acting and double acting actuators are offered as

standard. Intrinsically safe versions are also available.

Bray’s BUS positioners offer all Series 6A features plus increased network communication and remote access to positioner parameters and diagnostics.

Features

ON-LINE ADAPTIVE CONTROL: During operation, the unit continually optimizes control behaviors and travel times in response to changes in line media pressure.

DIAGNOSTICS: Bray’s Series 6A positioners feature corrective and preventative maintenance self-diagnostic checks. All diagnostics run constantly, may be continually monitored, and recorded.

AIR SUPPLY MONITOR: An additional feature of the Series 6A is an internal monitor that transmits a fault signal alarm if the air supply fails. The alarm is shown locally on the LCD and may be sent to the remote control panel.

LOCAL POSITION ADJUSTMENT: Valve position can be manually adjusted locally by removing the housing cover, then using the push buttons to override the remote command signal.

FLOW RESTRICTORS: Precise control of even the smallest pneumatic actuators through internal Flow Restrictors.

POSITION INDICATOR: In addition to the LCD display, valve position is clearly shown over a distance by a yellow indicator.

LOCKING DEVICE: For high vibration applications, the Series 6A features, as standard, a friction clutch locking device.