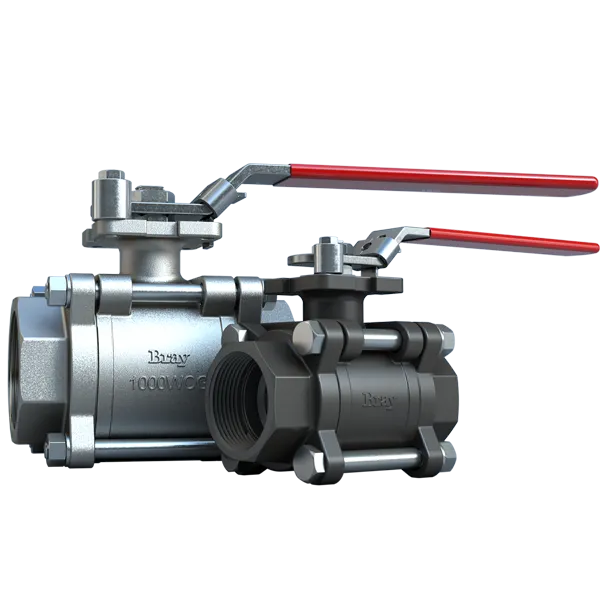

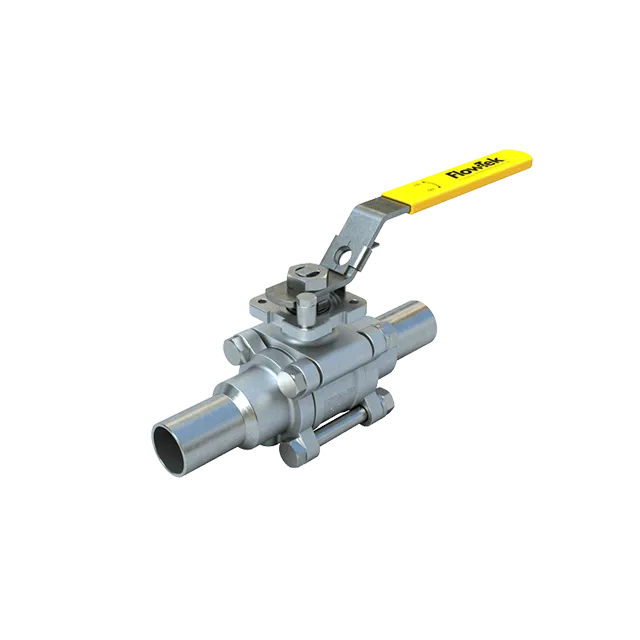

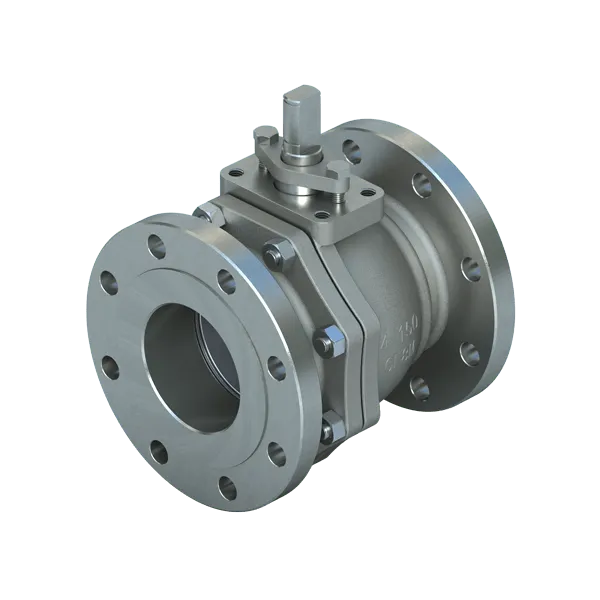

The Bray Series 7000/8000 3-piece Ball Valves provide maximum flexibility with threaded, Socket weld, butt weld and flanged end connections and a variety of high-performance seat materials.

Series 7000/8000 feature an integrated actuation mounting pad and available optional accessories and trims including, a media containment unit for fugitive emissions, internal cavity fillers, control valve inserts for characterized control valve applications, and internal electro-polishing for food handling.

The three-piece body design allows for easy in-line maintenance with replaceable components for lower maintenance cost and lower total cost of ownership across the life of the valve.