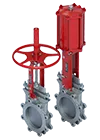

Bidirectional Knife Gate Valve

Series 768

Heavy-Duty Solution for High-Pressure Slurry Handling Applications

Replaceable Sleeves Ensure Quick Maintenance and Durability

Engineered for Long Service Life in Demanding Conditions

The Knife Gate Valve Series 768 an engineered solution for heavy-duty slurry handling applications. With a compact wafer face-to-face dimension, this valve provides an efficient and space-saving solution for diverse slurry handling needs, equipped with Bray SlurryShield Technology and can be a direct replacement for conventional knife gate valves.The valve features a design incorporating twin elastomer sleeves and a self-cleaning gate. The gate is designed to withstand 1.1 times the pressure rating of the valve, ensuring durability in high-pressure applications. Higher pressure ratings can be achieved by utilizing higher yield gate materials such as Duplex 2205 or 17-4PH stainless steel. Sleeves can be replaced onsite enabling the valve to return to service quickly for a long service life.Certifications include the CRN and PED Category I Module A for Group 2 liquids, ensuring compliance with industry standards and regulations.The Knife Gate Valve Series 768 provide a guarantee in design and performance, providing effectiveness in heavy-duty slurry handling applications is such as mining, HPAL/POX, Chemical among other industries.

Specifications

Size Range

NPS 2 to 24 / DN 50 to 600

Body Materials

Ductile Iron, Carbon Steel and Stainless Steel

Maximum Allowable Operating Pressure

NPS 2 to 16: 150psi / DN 50 to 400: 10bar

NPS 18 to 24: 90psi / DN 450 to 600: 6.2bar

(Higher pressures available with select materials)

NPS 18 to 24: 90psi / DN 450 to 600: 6.2bar

(Higher pressures available with select materials)

Stem Materials

304 Stainless Steel

Body Style

Two Piece Bolted: Wafer

Gate Materials

304, 316, 317 Stainless Steel, SAF 2507, SAF 2205, 17-4PH, Hastelloy® C, Monel®,

Seat Material Temperature Range

Natural Rubber: -60° to 165°F (-51° to 74°C)

EPDM: -65° to 248°F (-54° to 120°C)

EPDM: -65° to 248°F (-54° to 120°C)

Design Standard

Manufacturer Standard

Wiper Materials

EPDM

Testing Standard

Manufacturer Standard

Certifications

ATEX, CRN, PED, PE(S)R, TR CU, UA TR

Face to Face

Manufacturer Standard

Actuator Options

Handwheel, Bevel Gear, Pneumatic, Hydraulic, Electric

applications

Slurry

Downloads

Sales Data Sheet

Slurryshield® Bidirectional Heavy Duty Slurry Valves 768

Download

English

Sales Data Sheet

KCA Linear Sensor

Download

English

Product Brochure

Series 768 Bray Slurryshield® Bidirectional Knife Gate Valve

Download

English

Product Brochure

Knife Gate And Slurry Valves Product Guide

Download

English

IOM Manual

Series 768 Bray Slurryshield® Bidirectional Knife Gate Valve

Download

English

Recommended Specs

Bidirectional Knife Gate Series 768 Wafer Slurry Valve

Download

English

More Details

Features & Benefits

- Protective stem cover is standard increasing cycle life in hazardous environments.

- Fully encapsulated J-ring providing sleeve reinforcement and memory assist, guaranteeing bidirectional zero leakage performance.

- In the open position, the energized sleeves shield all metal components from direct contact with the flowing process media.

- Robust gate designed for slurry applications and available in a wide range of corrosion resistant alloys.

- Full port design provides unobstructed flow path, extending sleeve life and minimizing pressure drop across the valve.

- Two-piece bolted body allows for easy maintenance and is drilled and tapped to a variety of flange standards.

- Optional bottom flush plate with tapped ports allows for safe discharge of media and easy flush water connection.

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

Optimized Valves for Metals & Mining

Solutions for Mining Industry

Our durable valves, actuators, and controls are built for challenging mining and refining processes, handling abrasive, corrosive chemicals in aluminum, copper, gold, and more.

Explore Our Mining Products-copy.webp)

Copper Mining, Mineral Processing, Refining & Production

Copper Mining

Bray valves, actuators, controls and accessories are engineered to deliver reliable service for copper mining, copper concentrates production, smelting and electrolysis around the world.

Explorer Now

.webp)

.webp)