Bidirectional Knife Gate Valve

Series 762

Heavy-Duty Slurry Valve with Zero-Leakage Shutoff for Demanding Industrial Applications

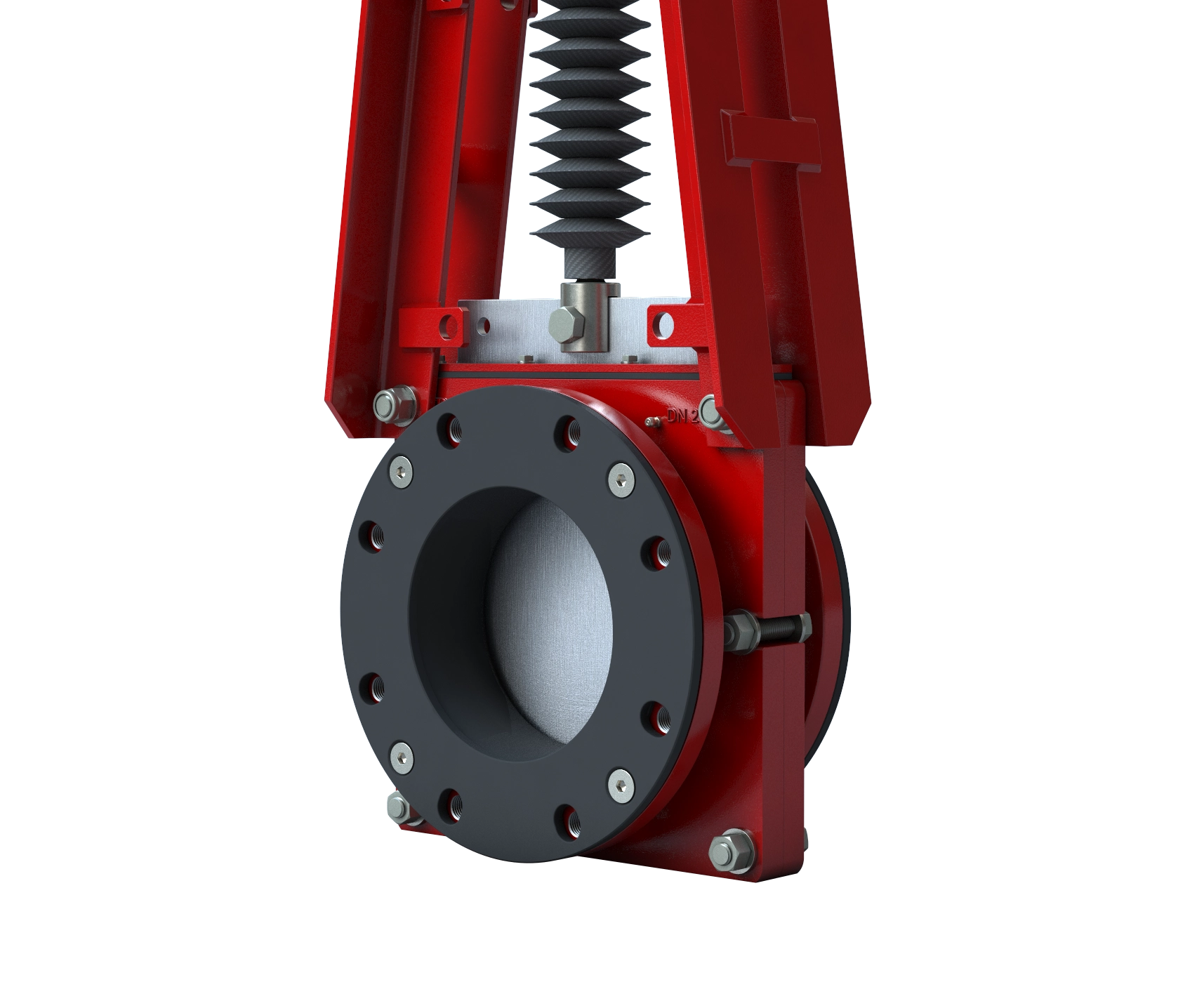

Protective Stem Cover for Enhanced Durability in Harsh Environments

Heavy-Duty Slurry Valve with Advanced SlurryShield Technology

Specifications

Carbon Steel and Stainless Steel (NPS 30 to 48 / DN 750 to 1200)

Other Materials upon request

Buna-N: 194°F / 90°C

EPDM-HT: 302°F / 150°C

ASME B16.47 Class 150

NPS 26 to 42: 75psi / DN 650 to 1050: 5bar

NPS 48: 50psi / DN 1200: 3bar

Higher pressures available with select materials

HPAL/POX: Autoclave Application Process Pumps

Downloads

Sales Data Sheet

KCA Linear Sensor

Sales Data Sheet

Slurryshield® Bidirectional Heavy Duty Slurry Valves 762

Technical Sales Manual

Series 762 Bray Slurryshield® Bidirectional Knife Gate Valves

Product Brochure

Series 762 Bray Slurryshield® Bidirectional Knife Gate Valve

Product Brochure

Knife Gate And Slurry Valves Product Guide

IOM Manual

Series 762 Bidirectional Slurry Knife Gate Valves – Bray Slurryshield®

Recommended Specs

Bidirectional Knife Gate Series 762 Flanged Slurry ValveMore Details

Features & Benefits

- Protective stem cover is standard increasing cycle life in hazardous environments

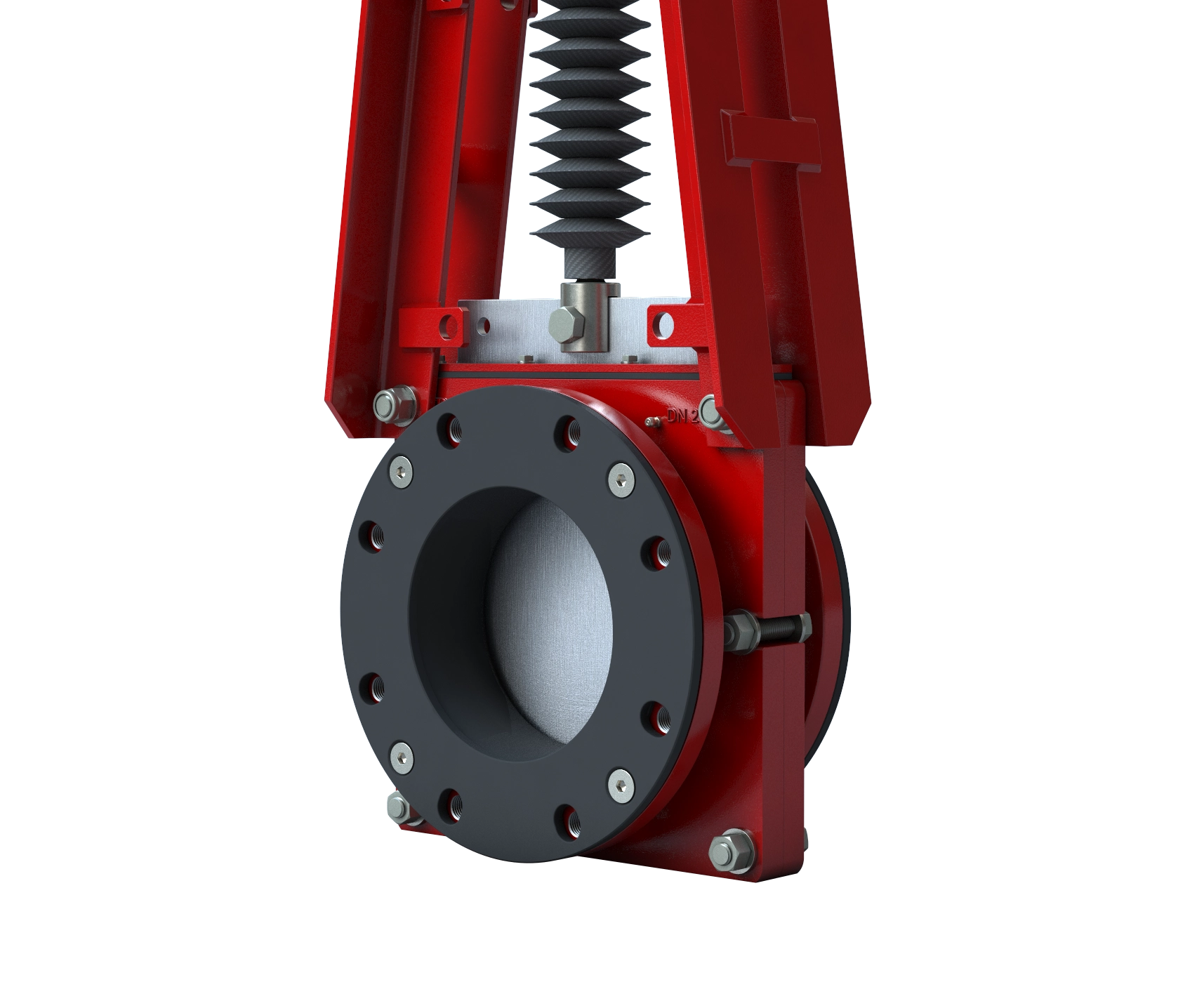

- Unique J-ring steel-reinforced, elastomer sleeve design provides energized, zero leakage shutoff in both directions. Retaining rings included as standard throughout the entire size range

- In the open position, the energized sleeves shield all metal components from direct contact with the flowing process media

- Robust gate designed for slurry applications and available in a wide range of corrosion resistant alloys to meet your application needs.

- Unrestricted flow path with minimal pressure drop achieved through full port valve design for extended sleeve life

- Designed with ample clearance for push-through allowing complete gate closure

- Flanged two-piece bolted body allows for easy maintenance and is drilled and tapped to ASME CL150 flange patterns as standard. Other drilling options available upon request

- Optional bottom flush plate with tapped ports, allowing for safe discharge of media and easy flush water connection

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

Optimized Valves for Metals & Mining

Solutions for Mining Industry

Our durable valves, actuators, and controls are built for challenging mining and refining processes, handling abrasive, corrosive chemicals in aluminum, copper, gold, and more.

Explore Our Mining Products-copy.webp)

Copper Mining, Mineral Processing, Refining & Production

Copper Mining

Bray valves, actuators, controls and accessories are engineered to deliver reliable service for copper mining, copper concentrates production, smelting and electrolysis around the world.

Explorer Now

Explore Bray's Innovative Solutions for Efficient, Reliable Operations in the Copper Mining Process

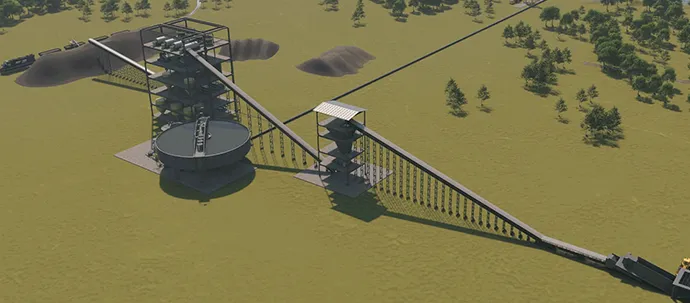

Coal Mining Virtual Plant

Explore our Virtual Coal Mining Plant and discover more about our Bray Solutions.

Copper Mining Industry Solutions

.webp)

.webp)