Quality

Following this general guideline provides good safety margin at the top and bottom of the range of operation of the control valve, increasing control fidelity.

Quality

Following this general guideline provides good safety margin at the top and bottom of the range of operation of the control valve, increasing control fidelity.

Reliability

Trust Bray's team of experts for your control valve needs.

-copy.webp)

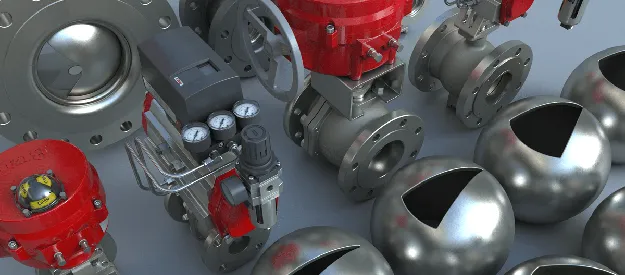

Traditionally, refineries heavily favor globe valves whereas pulp and paper plants favor Segmented ball valves and V Port ball valves. Although there are instances when one valve type is more appropriate than another, most control valve installations can be built around many types of control valves. Planning is the most important aspect including selecting materials and trim. The final selection of the type of control valve and trim should ultimately be dictated by the flow conditions required after carefully analyzing all the variables. The best way to accomplish this is by working closely with your salesperson and a Bray applications engineer. Bray Rotary Control valves have distinct advantages over linear control valves including; Higher Cv for the same size globe valve, resulting in higher control valve flow, allowing the use of smaller valve and actuation packages that reduce cost, have a smaller form factor, better packing performance and life, and Superior solids handling capabilities.

An undersized control valve will cause several problems including flow restriction (choked flow) - where the control valve is unable to deliver the required flow rate even when fully opened. Restricted flow can cause a momentary pressure drop resulting in cavitation, a phenomenon where the formation and then sudden implosion of bubbles, causes erosion. Another common control valve issue is Flashing. Flashing occurs when a liquid vaporizes due to a pressure drop across the vena contracta and is highly erosive. An oversized control valve sacrifices control resolution compared to a properly sized control valve, resulting in a loss of fidelity in the desired control range. The general rule is to size a control valve to utilize as much of the range as possible with the desired setpoint occurring at approximately 60%-80% of maximum being the ideal setpoint condition of the process.

Bray Sizing Program (BII Sizing) software is powerful control valve sizing software that performs control valve sizing calculations automatically and can help immensely with proper control valve sizing. BII sizing software produces an ISA specification sheet, based on your control valve flow requirements and can predict cavitation, noise and Cv at various openings ensuring accuracy. Although this software is provided free of charge and is generally considered to be reliable and accurate, it should not be considered a substitute for the assistance of an application engineer from the Bray team. Please consult your sales rep and or the factory for assistance with your control valve application needs.

Our performance tested Control Valve products comply with a variety of global certifications and approvals, including; API 607, NACE MR0175, PED 2014/68/EU, ATEX 94/9/EC, GOST-R, SIL IEC 61508 SC 3, ANSI FCI 70-2, NSF/ANSI 61-2008, Lloyd's Register, UL, ABS, Ukraine TR and more.

Learn Even More About How Bray’s Solutions Can Impact Your Business

Connect with Your Local Sales Expert