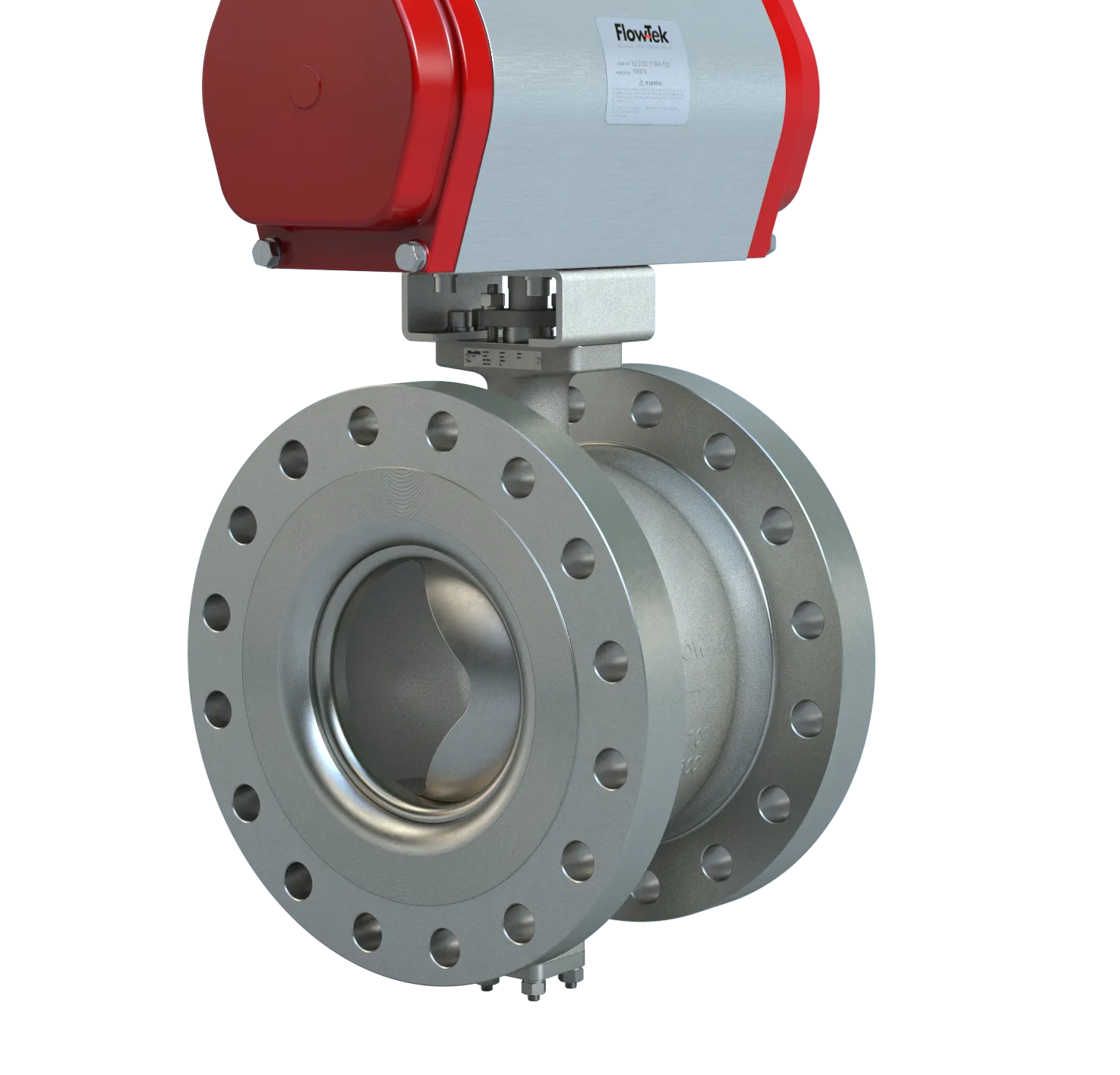

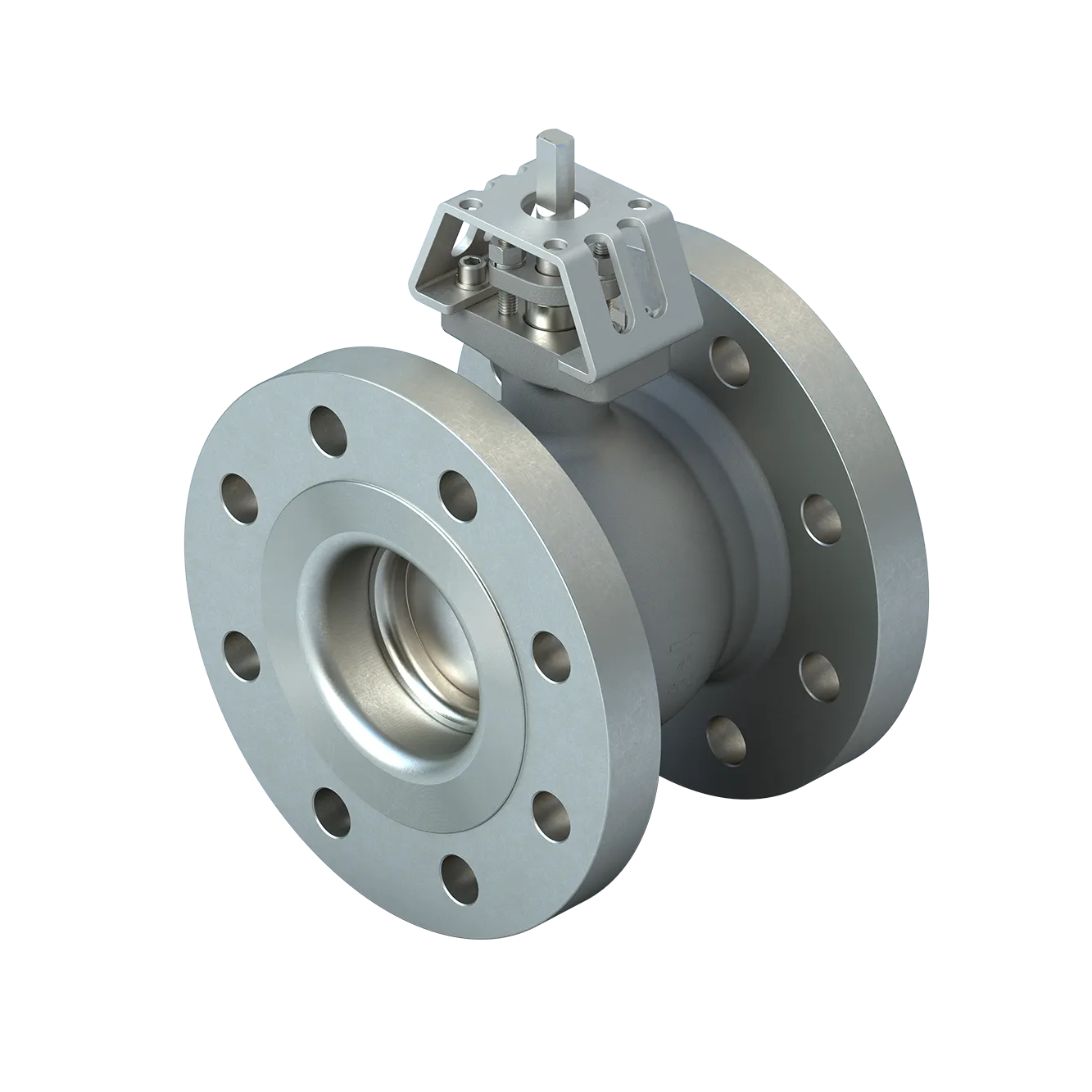

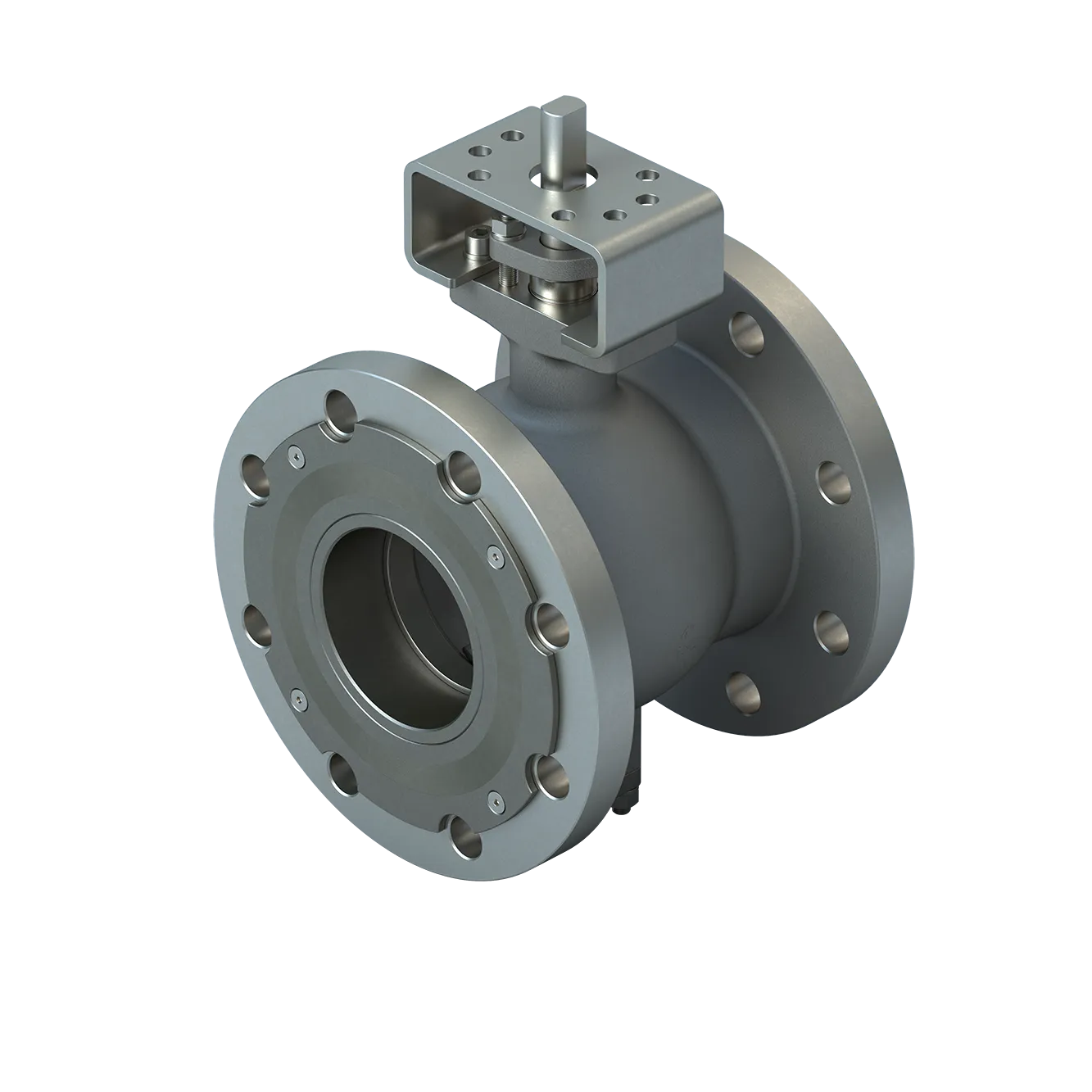

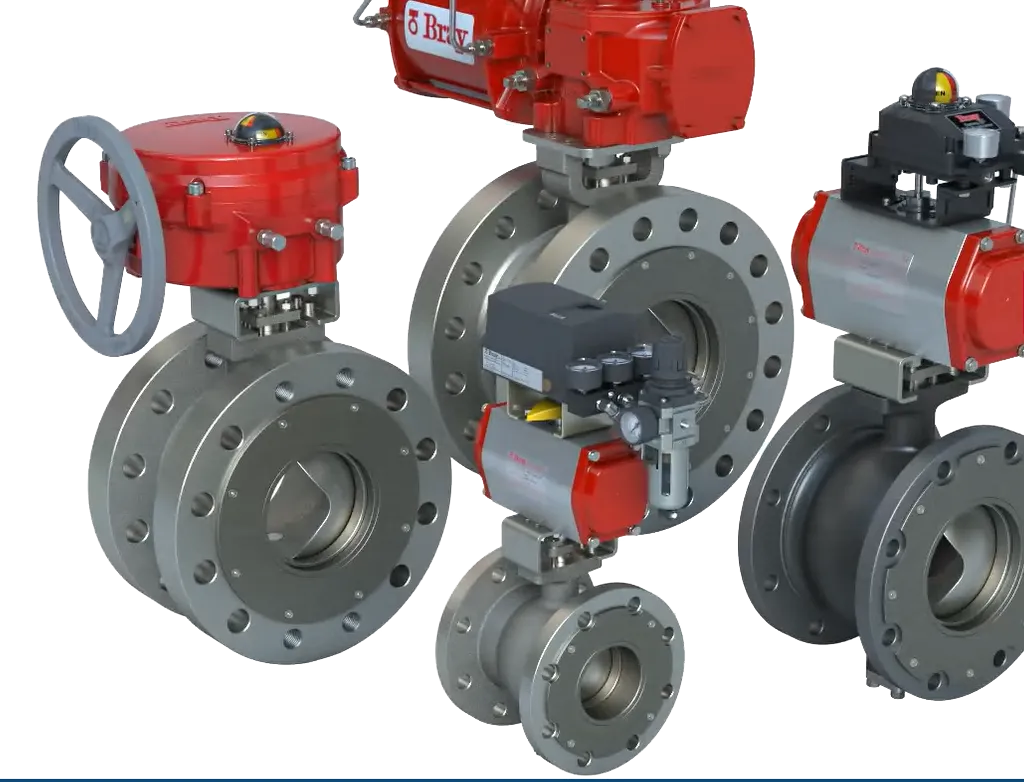

Bray’s Series 19/19L segmented ball valves combine the shearing action typically found in knife gate valves with the control characteristics and sealing performance found in ball valve. Series 19 and Series 19L segmented ball valves feature a characterized segment with wide rangeability and high flow capacity with exceptional rotary control valve performance. Designed for throttling applications, Series 19/19L segmented ball valves also deliver excellent sealing performance in on-off applications, achieving Class VI in resilient and Class IV sealing performance in metal seated trims.

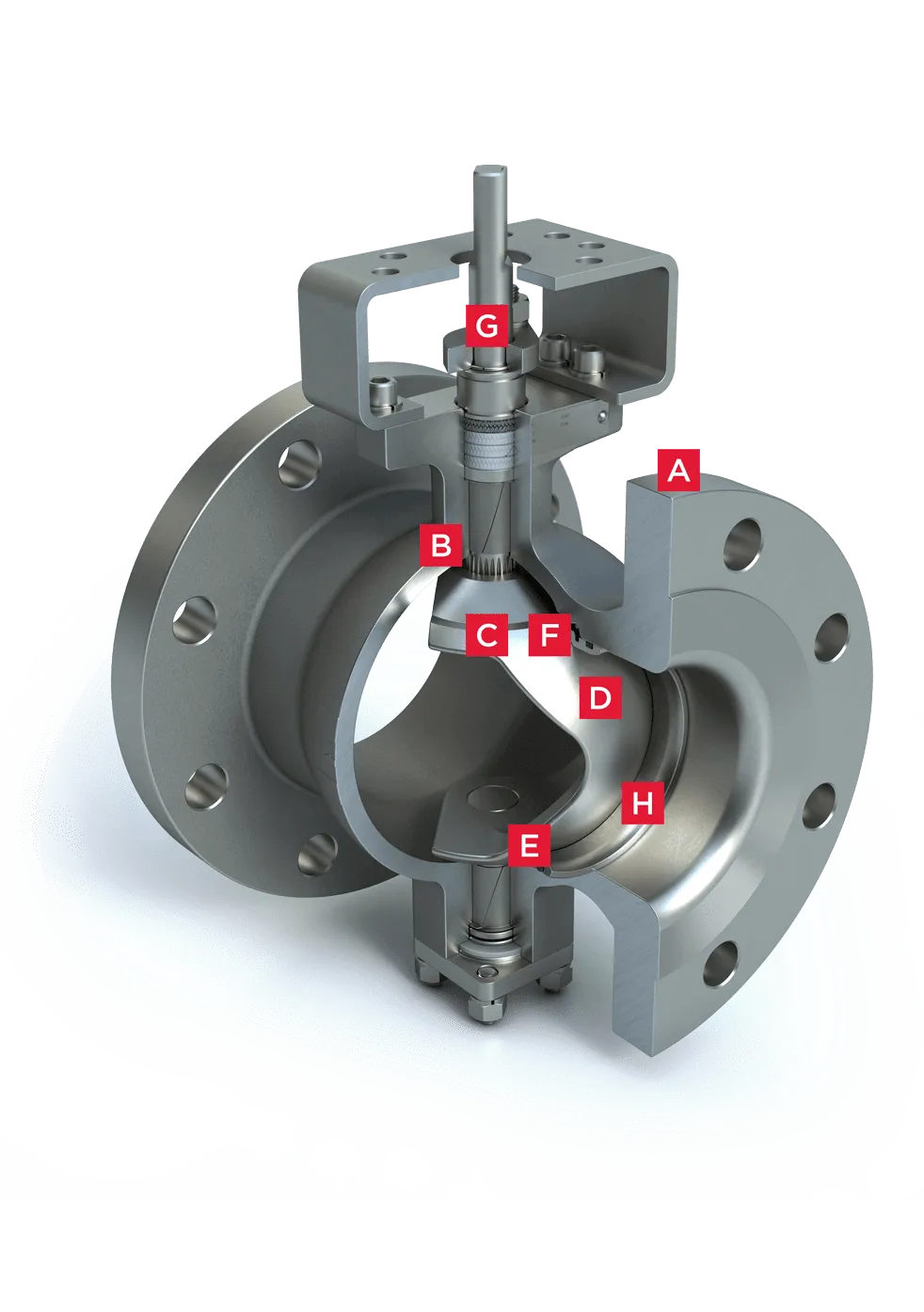

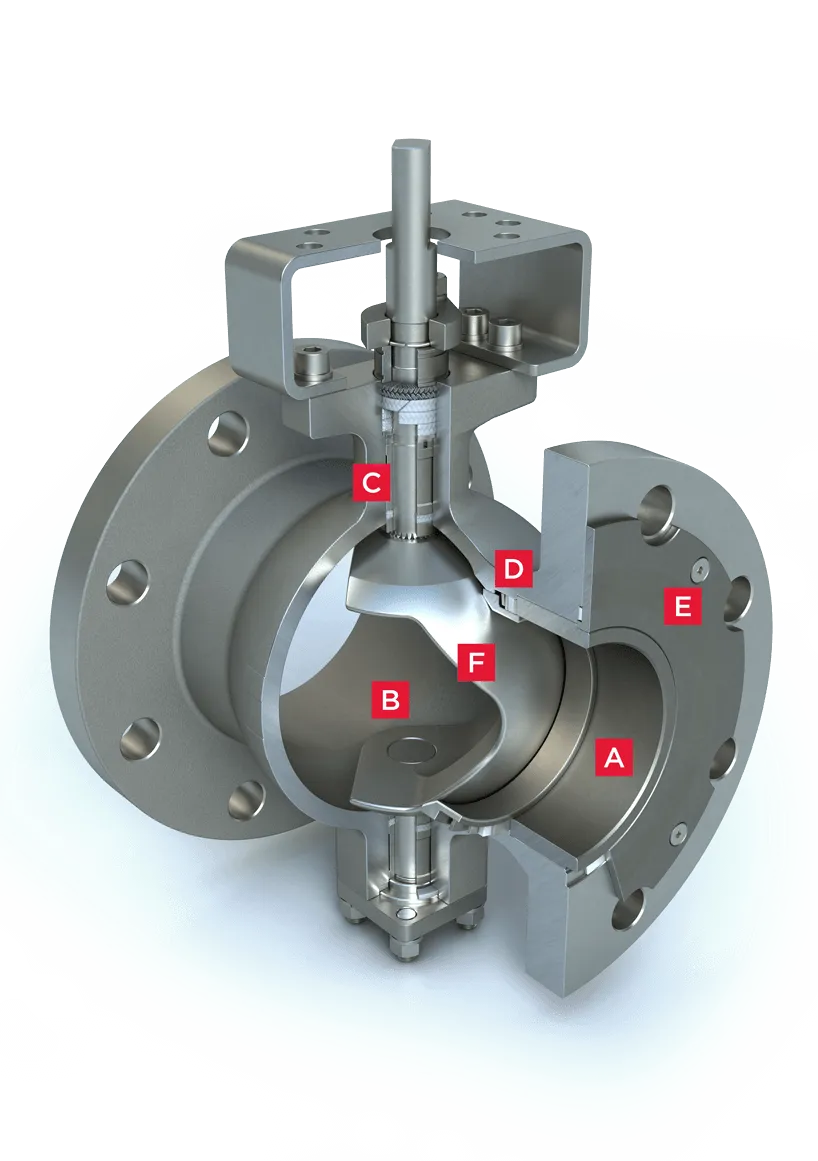

Designed in accordance with ASME B16.34 standards, Series 19/19L segmented ball valves feature a spring-assisted, pressure-balanced seat design. The springs maintains constant pressure against the segment, ensuring effective sealing at low differential pressures, while the pressure-balanced design also ensures effective sealing at full differential pressure with smooth, low torque operation. The Series 19/19L seat design also directs flow away from the sealing area, enhancing durability. The one-piece cast body, reduces weight and increases rigidity while eliminating potential leak paths.

Bray's Series 19L segmented Ball Valve further enhances the standard Series 19 for highly abrasive slurry and severe service applications. Bray's proprietary advanced coating technology is applied to the internal surfaces of the valve body and segment to provide increased hardness and resistance to erosion. This advanced coating technology provides higher bond strength over other commonly used coating technologies throughout the industry. A field-replaceable erosion-resistant liner is installed in the downstream bore to protect the body from impingement by high-velocity abrasive flow media.

With multiple coatings and trims available in a variety of configurations for different service conditions, Series 19 & 19L segmented valves are ideal for use in a wide variety of industries and applications where the increased durability and reliability extends service intervals, minimizes downtime and improves your bottom line.