More Details

Features & Benefits

-

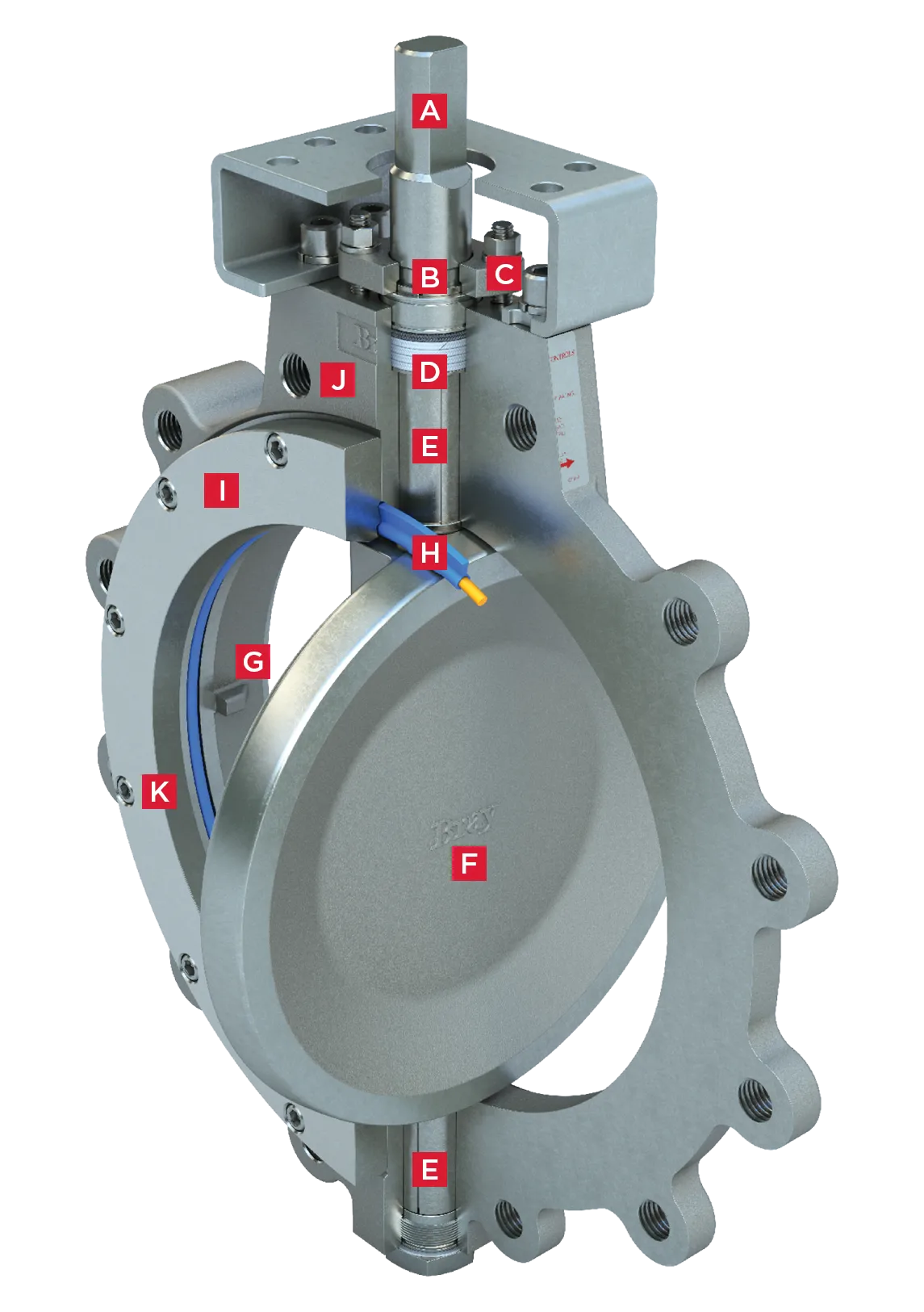

A. Stem Design

High-strength, one-piece stem design is standardized for interchangeability of Bray actuators.

-

B. Blowout-Proof Stem

The stem retention design does not rely on actuation components to prevent stem blowout.

-

C. Adjustable Stem Packing

Easy access allows simple quarter-turn field adjustments without actuator removal.

-

D. Stem Seal System

PTFE packing rings with carbon fiber anti-extrusion ring provides constant compression for a positive seal around the stem. Options are available for high temperature, high cycle and firesafe applications.

-

E. Stem Bearings

Top and bottom bearings securely support the stem, provide excellent corrosion resistance, and minimize deflection from high temperatures and mechanical loading forces.

-

F. Disc

The disc is engineered to maximize flow and minimize resistance for optimal flow rates.

-

G. Internal Over-travel Stop

Designed to minimize possible seat damage — extending the service life of the seat.

-

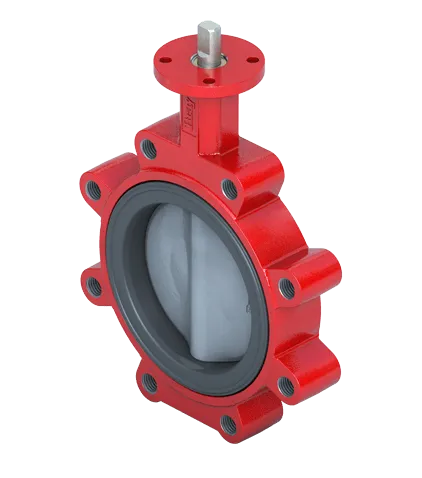

H. Bidirectional Resilient Seat

Provides bidirectional zero-leakage sealing while isolating the energizer from line media.

-

I. Full-faced Seat Retainer

Cap screws located outside sealing area are protected from corrosion while allowing simple seat replacement.

-

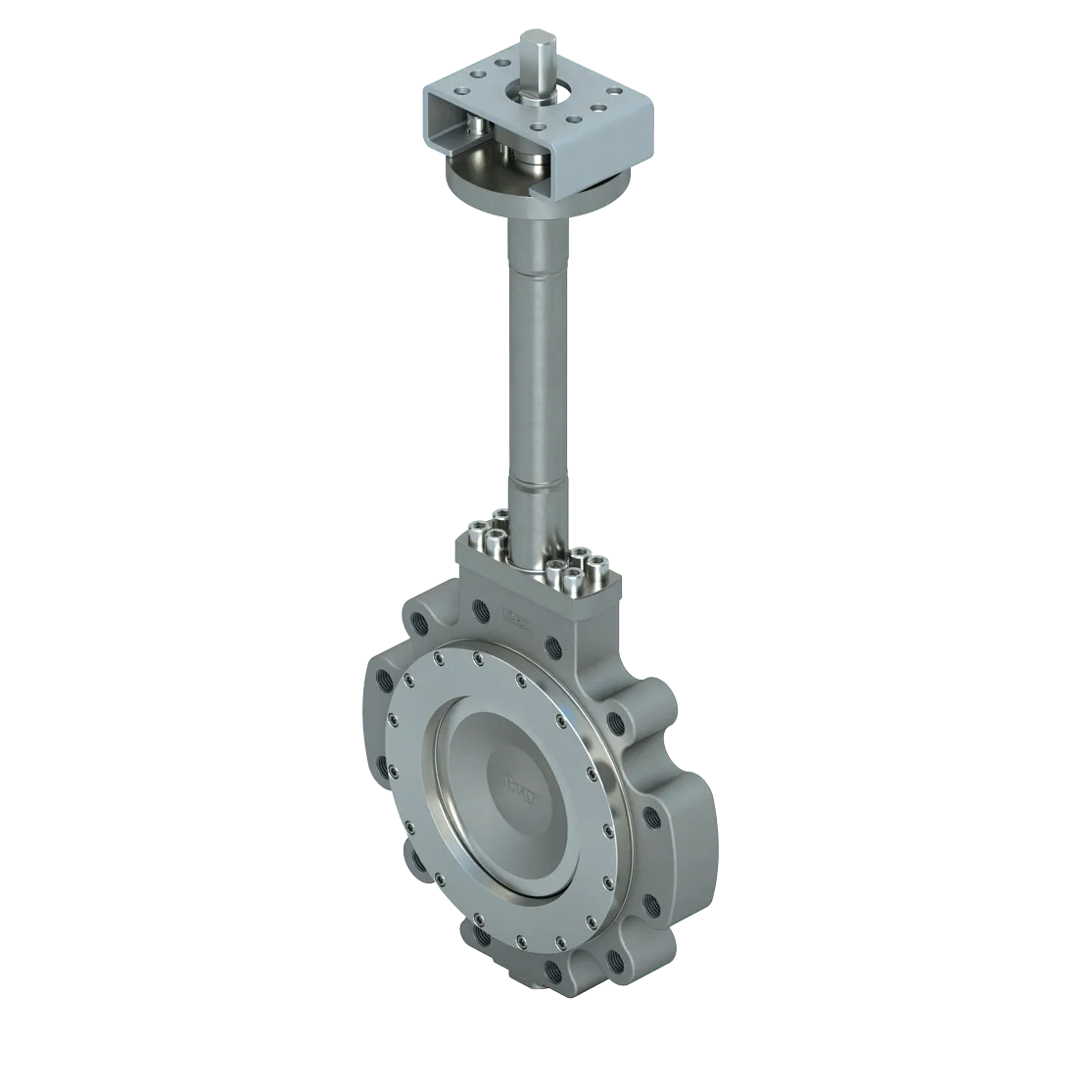

J. Body

Extended neck allows access to stem packing adjustments and actuator mounting when valve is fully insulated.

-

K. Dead-end Service

Lug and double-flanged bodies are full rated for bidirectional dead-end service.

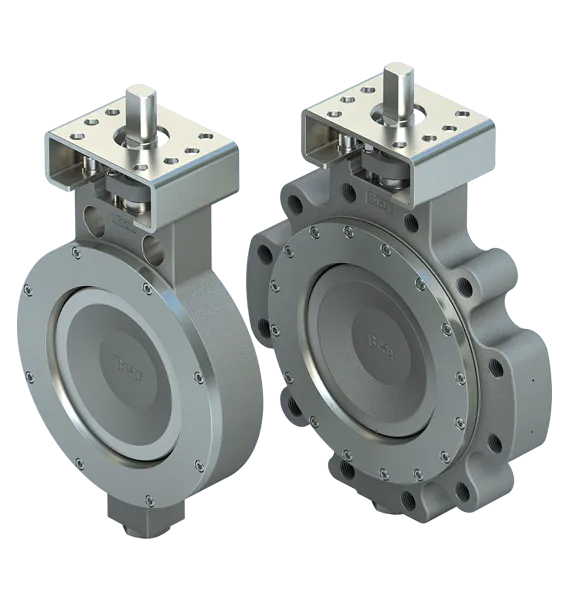

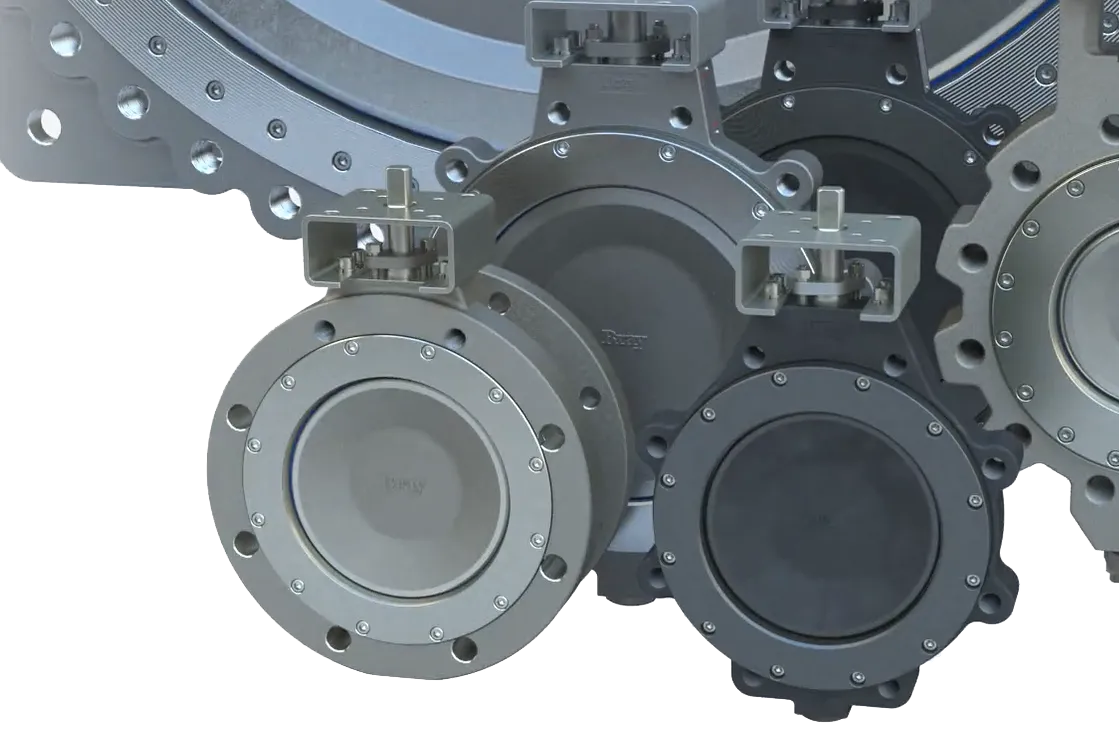

Series 40/41/4A

Up to 285 psi (19.6 bar)

Valve Sizes (NPS)

| Model | Body Style | Resilient Seated | Firesafe | Metal Seated |

|---|---|---|---|---|

| 40 | Wafer | 2 to 66 | 2 to 48 | 2½ to 36 |

| 41 | Lug | 2 to 66 | 2 to 48 | 2½ to 36 |

| 4A | Double Flanged | 2 to 54 | 2 to 48 | 2½ to 36 |

Valve Sizes (DN)

| Model | Body Style | Resilient Seated | Firesafe | Metal Seated |

|---|---|---|---|---|

| 40 | Wafer | 50 to 1500 | 50 to 1200 | 65 to 900 |

| 41 | Lug | 50 to 1500 | 50 to 1200 | 65 to 900 |

| 4A | Double Flanged | 50 to 1400 | 50 to 1200 | 65 to 900 |

Series 42/43/4B

Up to 740 psi (51 bar)

Valve Sizes (NPS)

| Model | Body Style | Resilient Seated | Firesafe | Metal Seated |

|---|---|---|---|---|

| 42 | Wafer | 2 to 36 | 2 to 36 | 2½ to 30 |

| 43 | Lug | 2 to 54 | 2 to 36 | 2½ to 30 |

| 4B | Double Flanged | 3 to 42 | 2 to 36 | 2½ to 30 |

Valve Sizes (DN)

| Model | Body Style | Resilient Seated | Firesafe | Metal Seated |

|---|---|---|---|---|

| 42 | Wafer | 50 to 900 | 50 to 900 | 65 to 750 |

| 43 | Lug | 50 to 1400 | 50 to 900 | 65 to 750 |

| 4B | Double Flanged | 80 to 900 | 50 to 900 | 65 to 750 |

Series 44/45

Up to 1440 psi (100 bar)

Valve Sizes (NPS)

| Model | Body Style | Resilient Seated | Firesafe | Metal Seated |

|---|---|---|---|---|

| 44 | Wafer | 3 to 24 | 3 to 24 | 3 to 12 |

| 45 | Lug | 3 to 36 | 3 to 36 | 4 to 12 |

Valve Sizes (DN)

| Model | Body Style | Resilient Seated | Firesafe | Metal Seated |

|---|---|---|---|---|

| 44 | Wafer | 80 to 600 | 80 to 600 | 80 to 300 |

| 45 | Lug | 80 to 900 | 80 to 900 | 100 to 300 |

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business