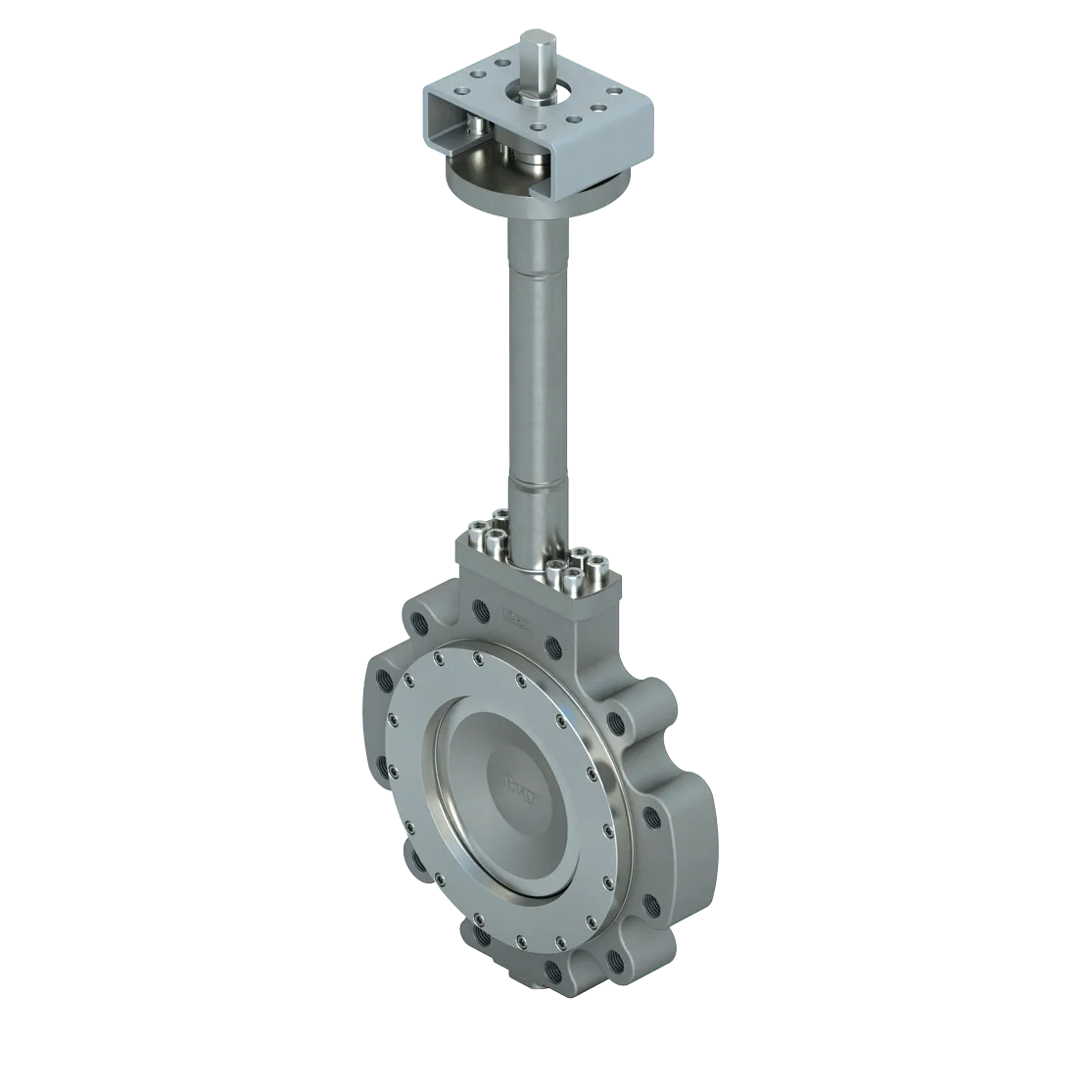

The Bray/McCannalok™ Metal Seated high performance butterfly valve has been extensively performance tested in our state-of-the-art technology center and test laboratory. The Inconel® 718 metal seat has been contoured to provide control, strength and flexibility in high temperature applications. The Technology Group’s design validation procedure includes cycle, torque and leakage testing to ensure long service life.

High Performance Butterfly Valve

McCannalok™ Metal Seated

Engineered High-Performance Valve Tested for Strength and Long-Term Durability

.webp)

.webp)

ASME Class 150-600 Certified with Inconel® 718 Seat for Durability and Reliable Performance

Bray McCannalok™ Metal Seated Valve for High Temperature Applications

Specifications

Size Range

NPS 2½ to 30 / DN 65 to 750

Body Materials

Stainless Steel, Carbon Steel

Temperature Range

Capabilities up to 900 °F (482°C)

3rd party-validated

3rd party-validated

Stem Materials

17-4 PH Stainless Steel: ASTM A564 Type 630 H1150D

Stainless Steel: ASTM A479 316 Strain Hardened Level 1

Stainless Steel: ASTM A479 316 Strain Hardened Level 1

Maximum Allowable Operating Pressure

ASME Class 150, 300, 600

Seat Materials

Inconel® 718

Shutoff Rating

Class IV

Disc Materials

Nitrided Stainless Steel, ASTM A351 CF8M

Body Style

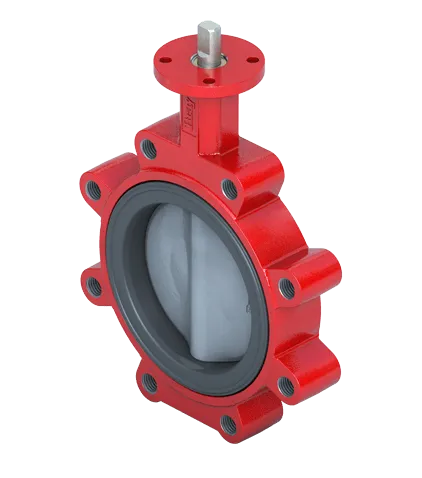

Wafer, Lug, Double Flanged

Design Standard

ASME B16.34, ASME VIII, API 609

Flange Drilling

ASME B16.5, EN 1092

Testing Standard

ANSI/FCI 70-2-2013, IEC 60534-4

Certifications

ABS, DNV, PED, PE(S)R

Face to Face

API 609, ISO 5752

Fugitive Emissions Standard

ISO 15848-1, API 641

applications

High temperature, Abrasive, Hot Oil, Hot Air & Gas, Saturated Steam, Slurries, Chemical Processing, Modulation and Control

Downloads

Sales Data Sheet

High Performance Butterfly Valve McCannalok™

Download

English

Technical Sales Manual

High Performance Butterfly Valves McCannalok™

Download

English

Product Brochure

High Performance Butterfly Valves McCannalok™ Metal Seated

Download

English

Product Brochure

Rotary Control Valve Brochure

Download

English

IOM Manual

High Performance Butterfly Valves McCannalok™ Series

Download

English

Selection Guide

Control Valves Version 2.0

Download

English

More Details

Features & Benefits

- Body Style: Wafer, Lug and Double Flanged

- ASME Class 150 and 300: 2 -1/2” – 30” (65mm - 750mm)

- ASME Class 600: 3” – 14” (80mm - 350mm)

- Capabilities up to 900 °F (482 °C)

- Wear-resistant Inconel® 718 metal seat provides industry leading low torque

- 3rd party validated high temperature tested

- High strength, anti-blowout one piece stem

- Nitrided disc for abrasion resistance

- Contoured disc to maximize flow

- Full face retaining ring protects seat in abrasive applications

- Easily accessible and adjustable stem packing

- Class IV bi-directional leakage rates through full pressure range tested in accordance to IEC 60534-4 and ANSI/FCI 70-2-2013

- Alternative flange drilling available

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

ISO-Certified Cleanroom Solutions for Superior Valve Integrity

Cleanroom Valve Services

Bray's state-of-the-art cleanroom facilities deliver ISO Class 6 to ISO Class 9 precision cleaning around the globe where valves are cleaned, inspected, bagged & tagged to meet the most stringent global standards, ensuring contamination-free valves.

Discover Our Precision Cleaning Solutions