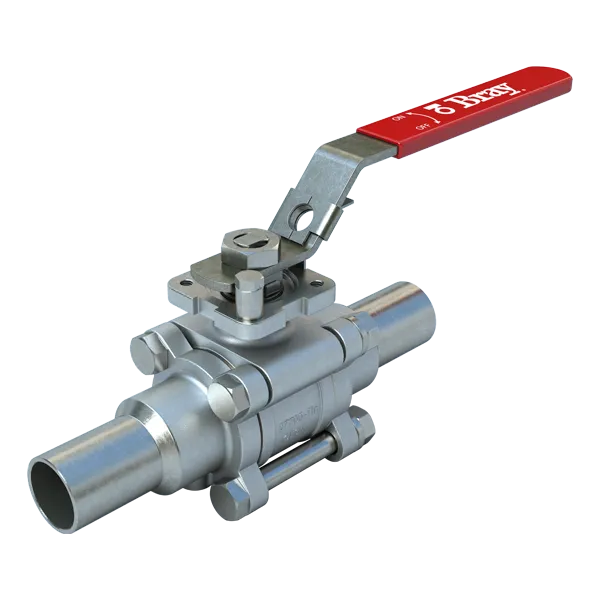

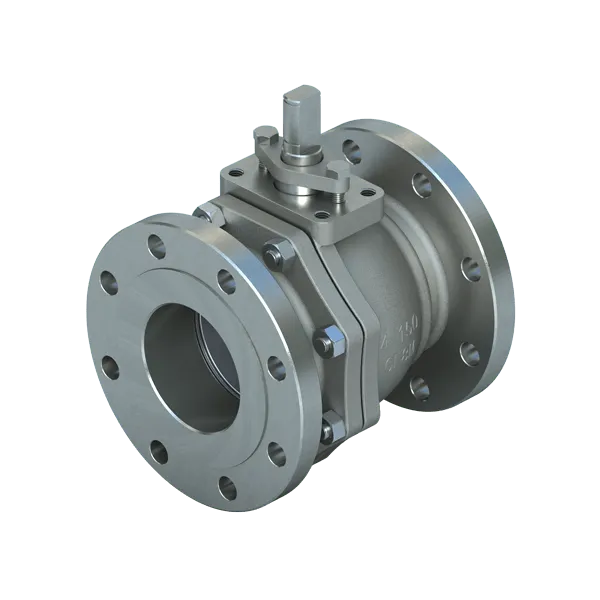

Bray’s V-Port (V-Ball) Rotary Control valves combine the benefits of a zero leakage, Class VI bubble-tight shut-off ball valve with the high-rangeability of a characterized control valve, delivering exceptional flow control, lower pressure drop and fast response times in a wide variety of control valve applications.

Offered as a drop-in replacement V-ball, for many of Bray’s quarter-turn ball valves, V-Port ball valves deliver a high flow coefficient (Cv), in a light weight, compact package. V-Port geometry is available in standard 30°, 60° and 90° ports and is available with custom characterized port geometry for highly specialized control valve applications.

All V-ball control valves adhere to multiple industry standards and certifications, ensuring their reliability and compliance with international regulations: API 607, ATEX, NACE MR0175, PED, PE(S)R, SIL, TR CU.

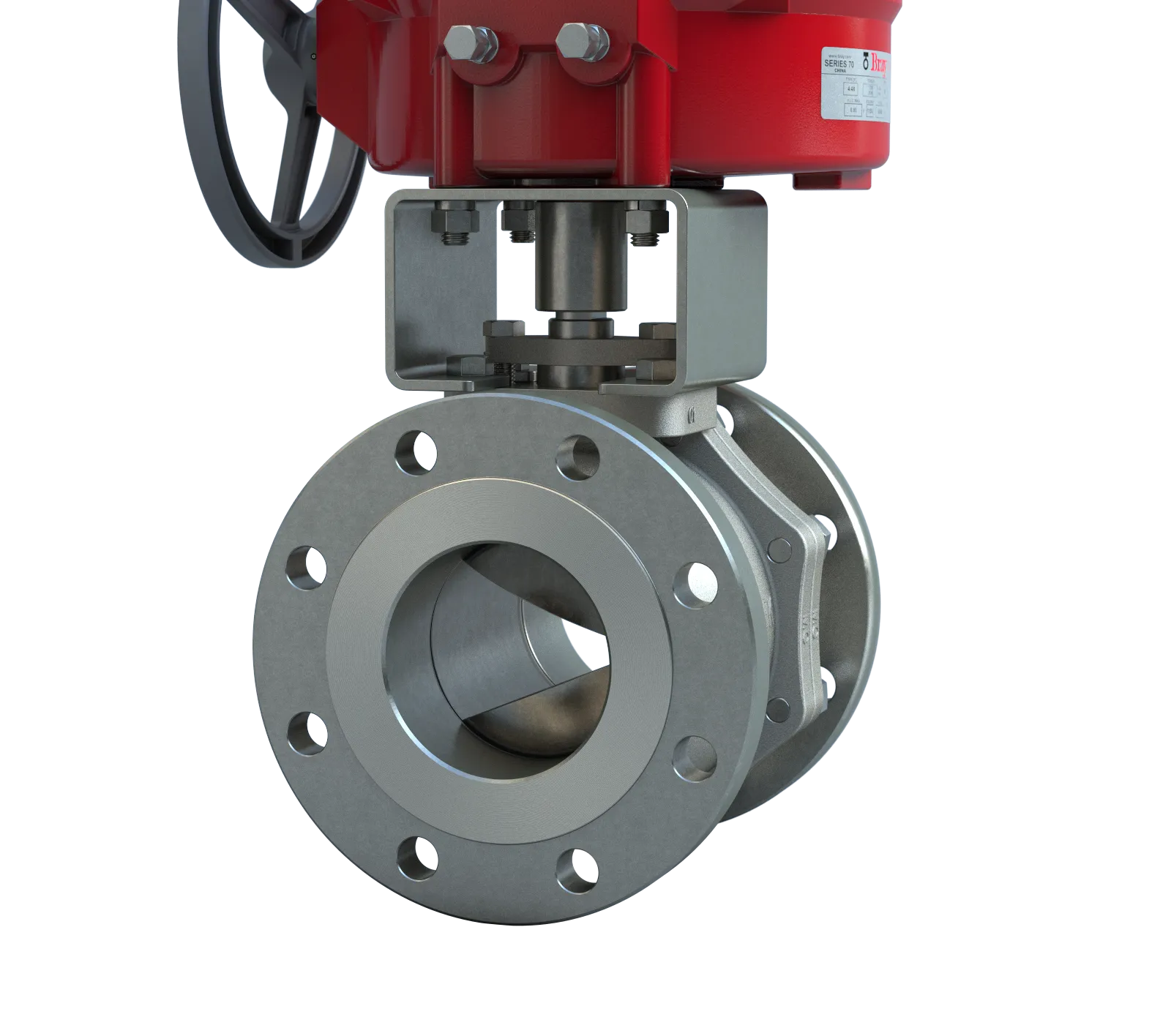

Ensuring optimized flow control for industrial valve automation requires complete control valve package including valve, actuator and valve controller. When combined with Bray’s World-Class Pneumatic, Electric, and Electro-Hydraulic actuator and control packages, Bray’s Characterized V-ball control valves deliver rangeability, repeatability and precise control.