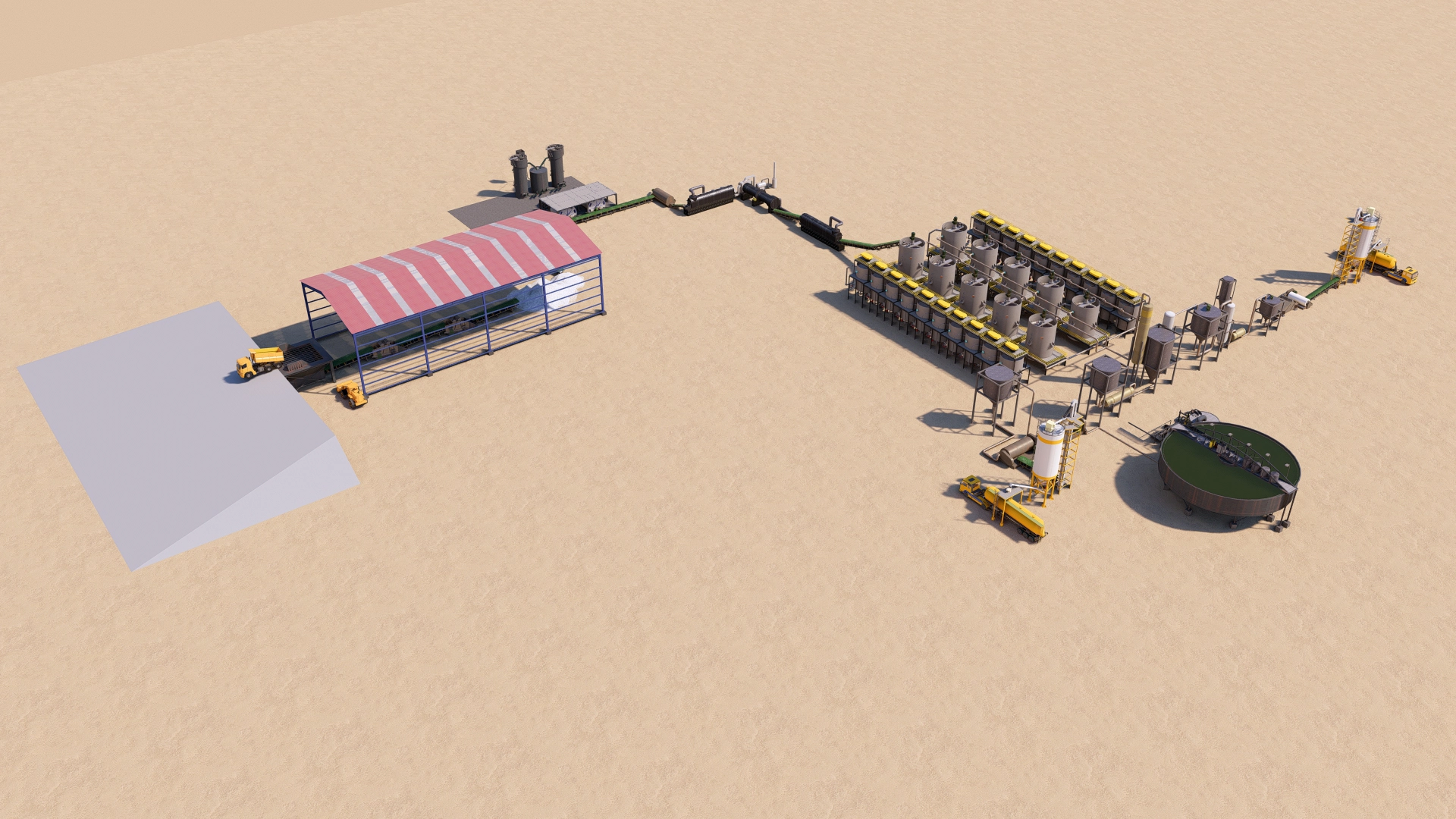

Lösungen für den Lithium-Bergbau

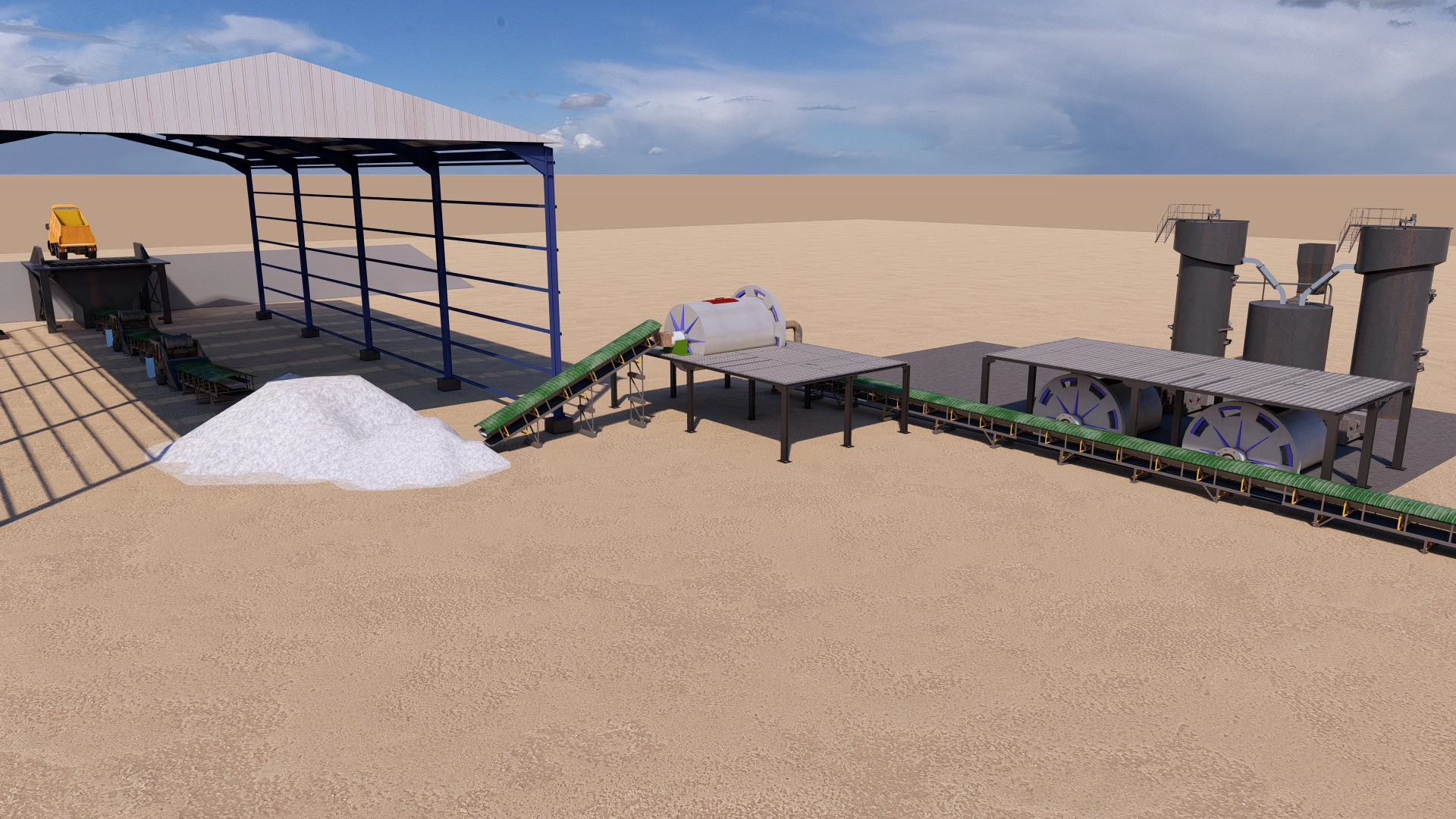

Mahlkreislauf

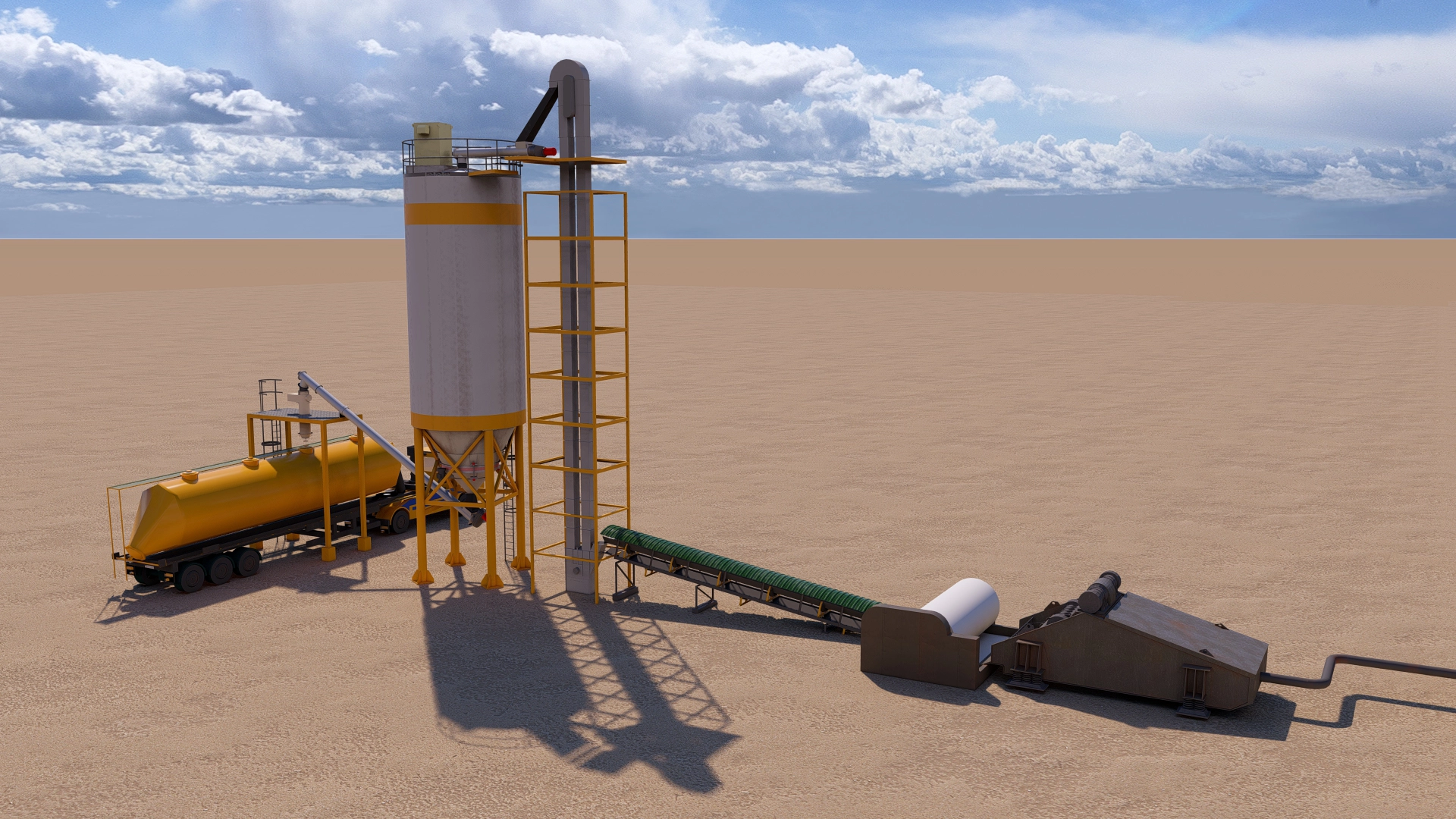

Fluidisierte Betten und Kalzinatoren

Laugung / Flotation

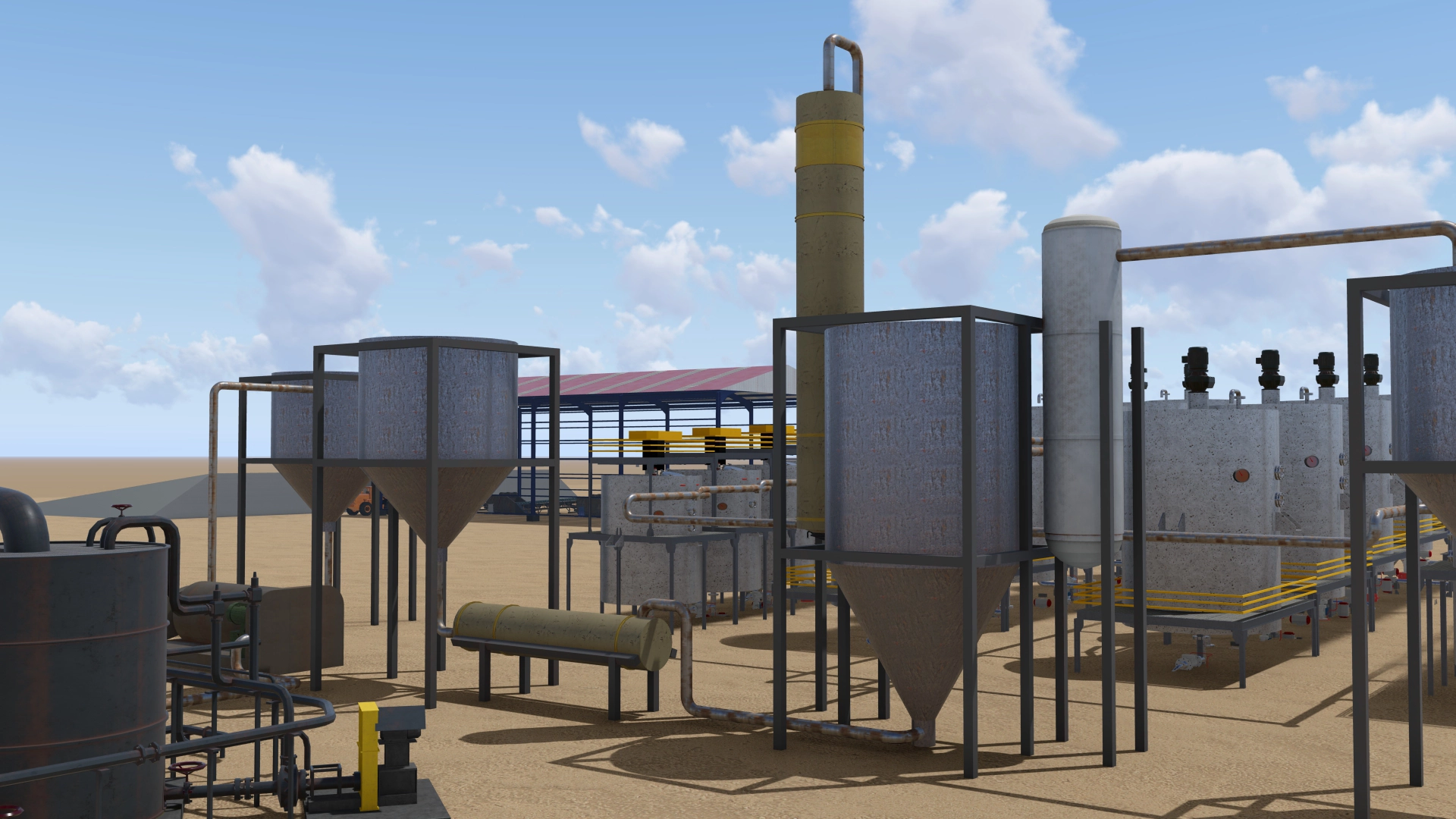

Verdampfung und Kristallisation

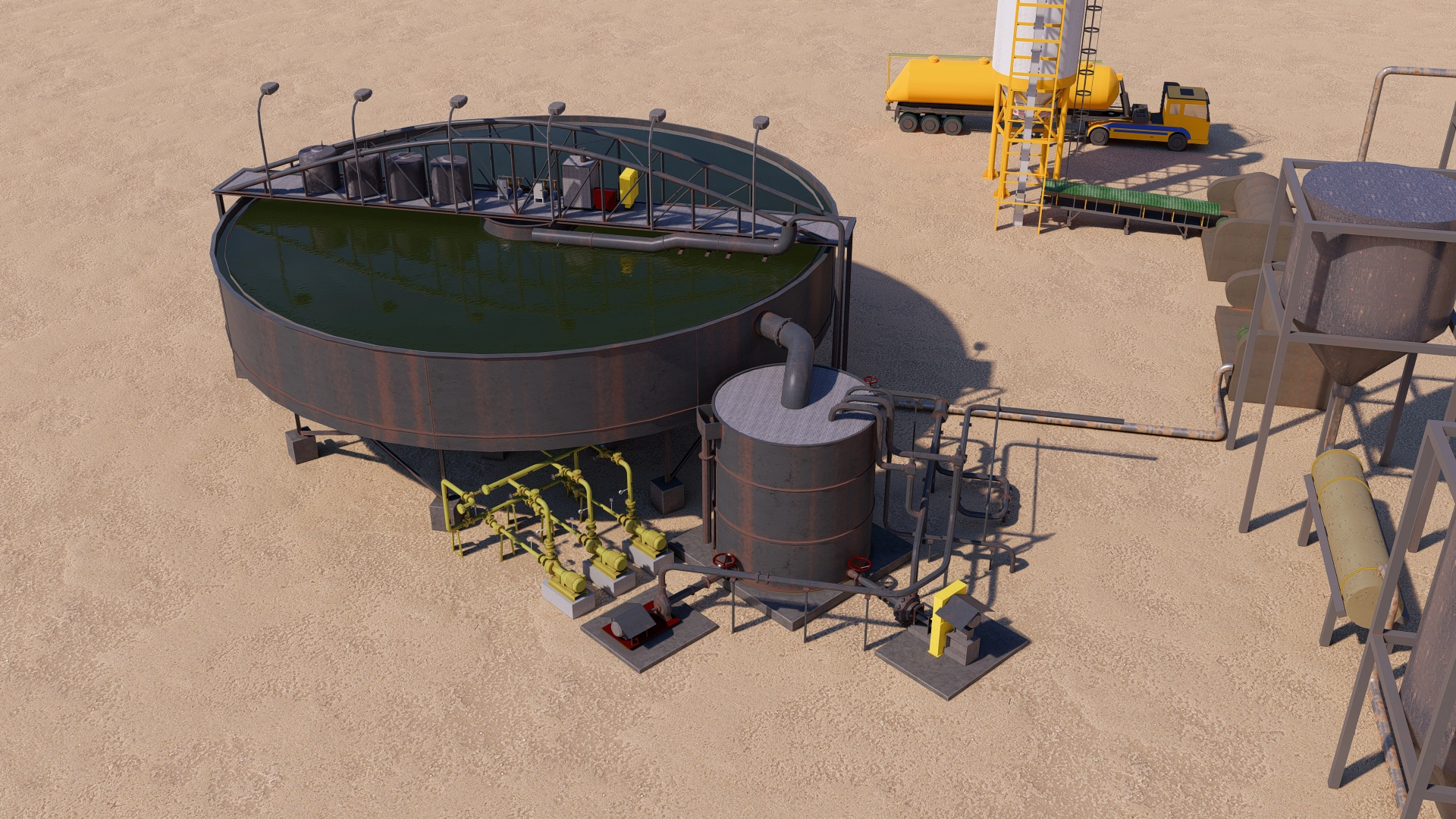

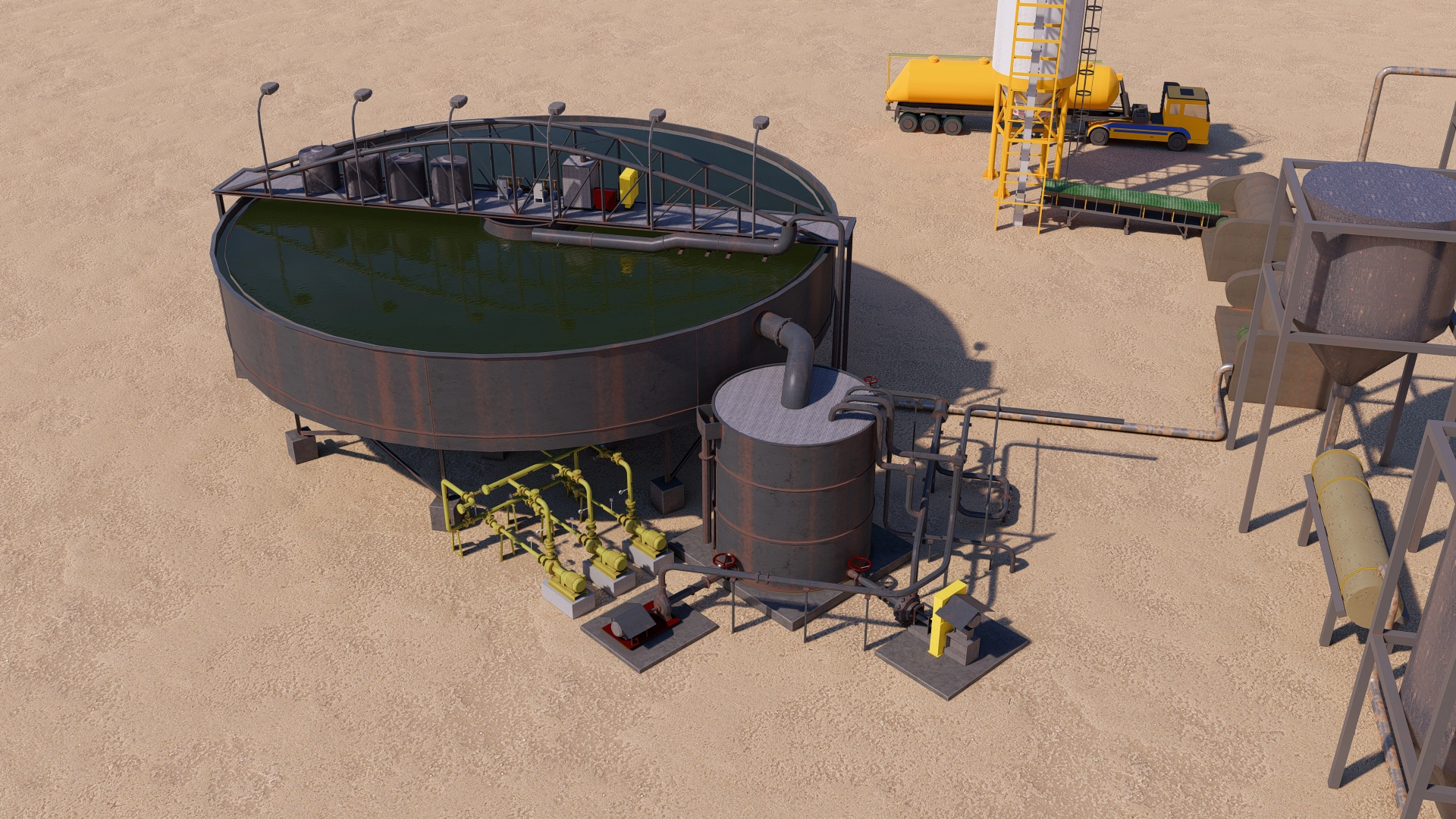

Verdickung

Lithium-Rückgewinnungstanks

Filtern und Trocknen

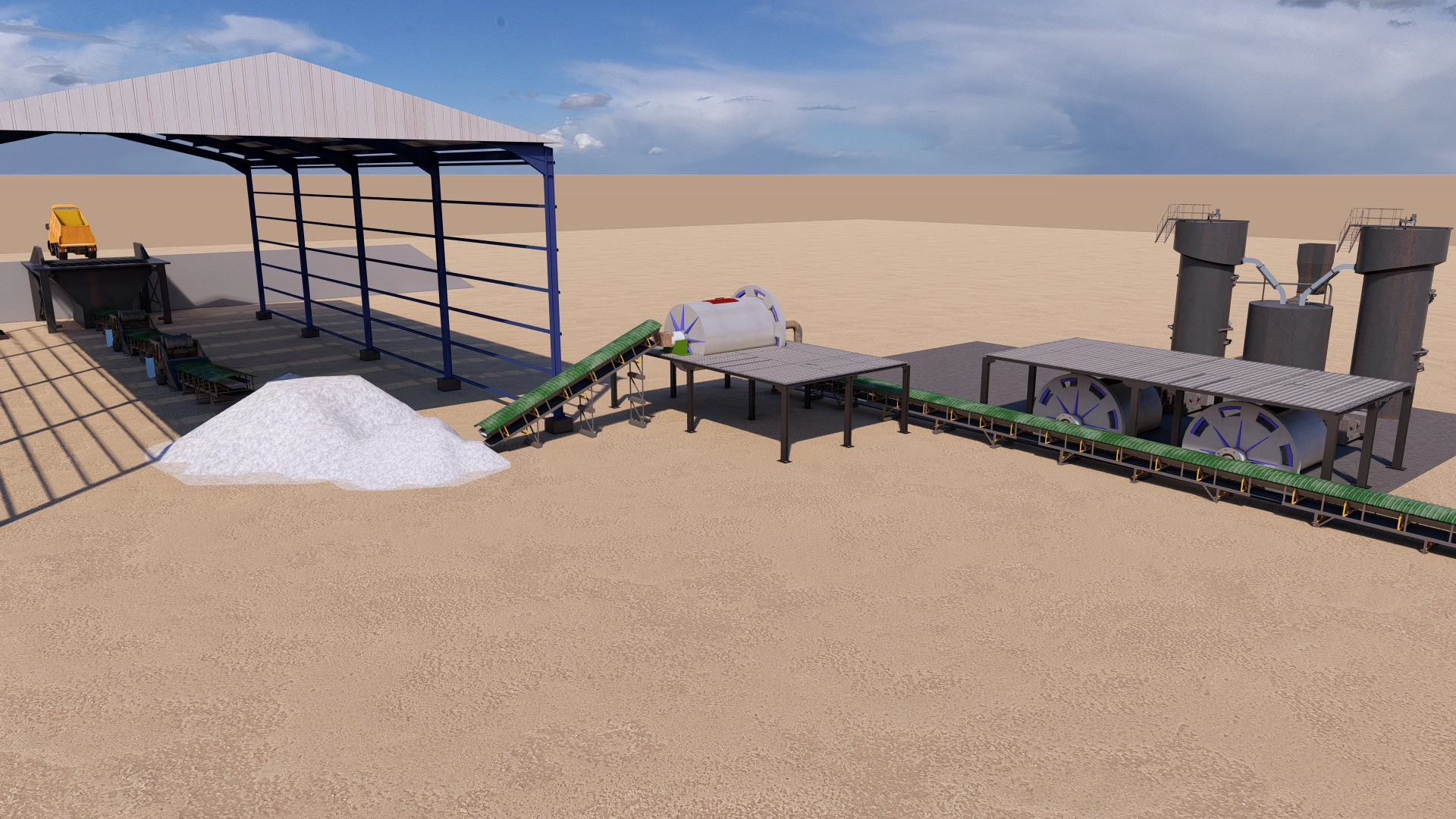

Mahlkreislauf

Spodumenerz wird zur Vorbereitung in kleiner Größen zerkleinert und gemahlen. Hydrit- und Dualamitreagenzien werden gemahlen und dem Verfahren beigegeben.

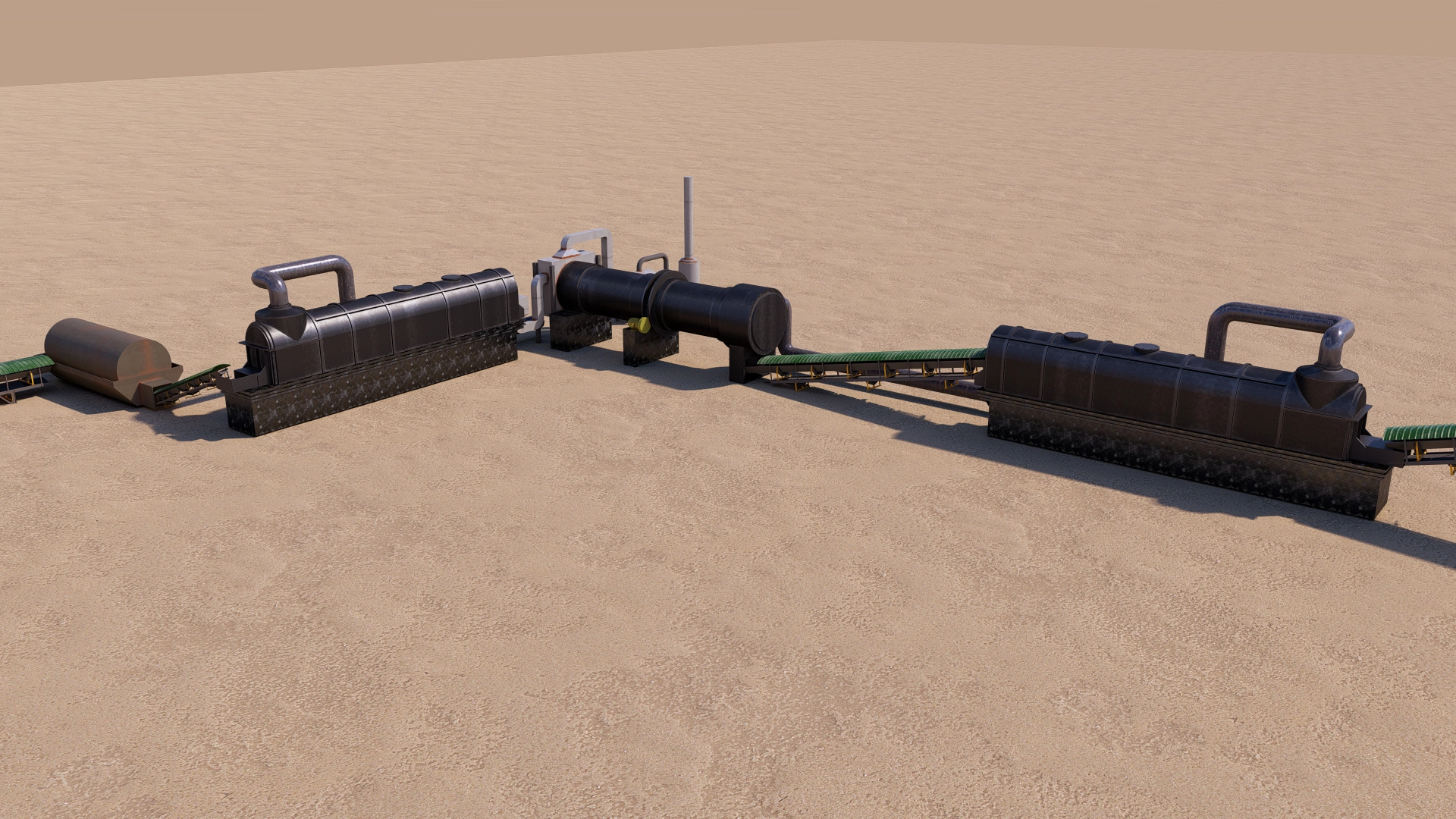

Fluidisierte Betten und Kalzinatoren

Lithium, Natrium und Kalium werden bei 1000 °C in wasserlösliche Lösungen umgewandelt und dann im Kalzinator luftgetrocknet.

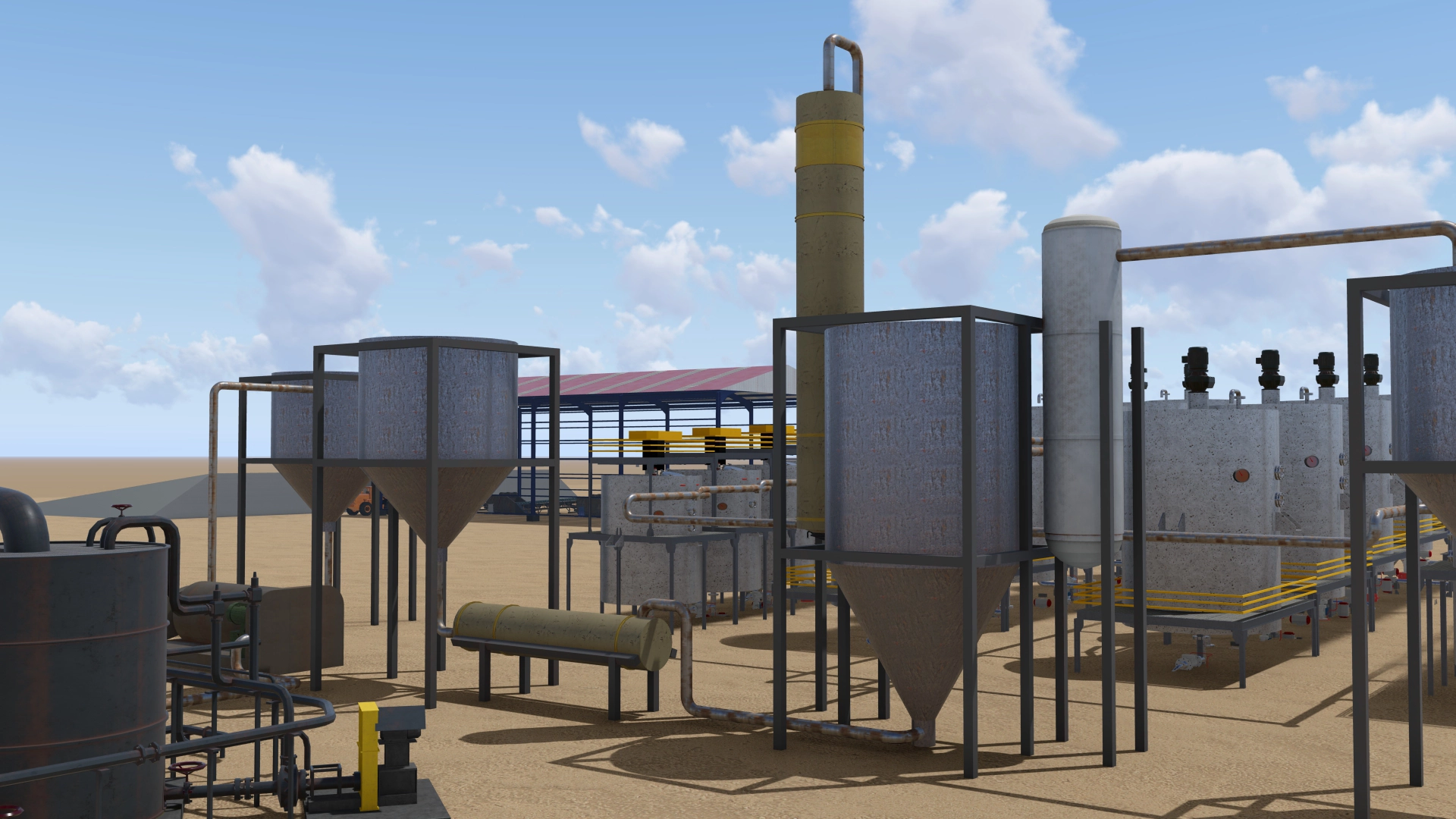

Laugung / Flotation

Gelöst, gemeinsam mit Spurenmengen an Magnesium und Kalzium. Andere Unreinheiten bleiben weiterhin unlöslich. Eine Laugenlösung wird beigeben, um die Lithiumkonzentration zu maximieren.

Verdampfung und Kristallisation

Eine geklärte Laugenlösung wird mit den zurückgewonnenen Lösungen vermischt und in die Verdampfer gegeben und das Lithiumsulfat wird stärker konzentriert.

Verdickung

Schlacke wird bei der Entnahme von überschüssigem Wasser durch die Verwendung von Schwerkraft zur Konzentrierung von feinen Feststoffen konzentriert. Die Schlackedichte wird für die nachgelagerte Filtration als Kaliumsulfat optimiert.

Lithium-Rückgewinnungstanks

Spuren an Kalzium und Magnesium werden aus dem Konzentrat entfernt. Dann wird Lithiumkarbonat durch Zugabe von Natriumkarbonat präzipitiert.

Filtern und Trocknen

Filternebenprodukte (Glaubersalz) und Lithiumkarbonat nach der Lithiumrückgewinnung oder Kaliumsulfat nach Verdickung, Waschen und Trocknen zum Abfüllen in Säcke.

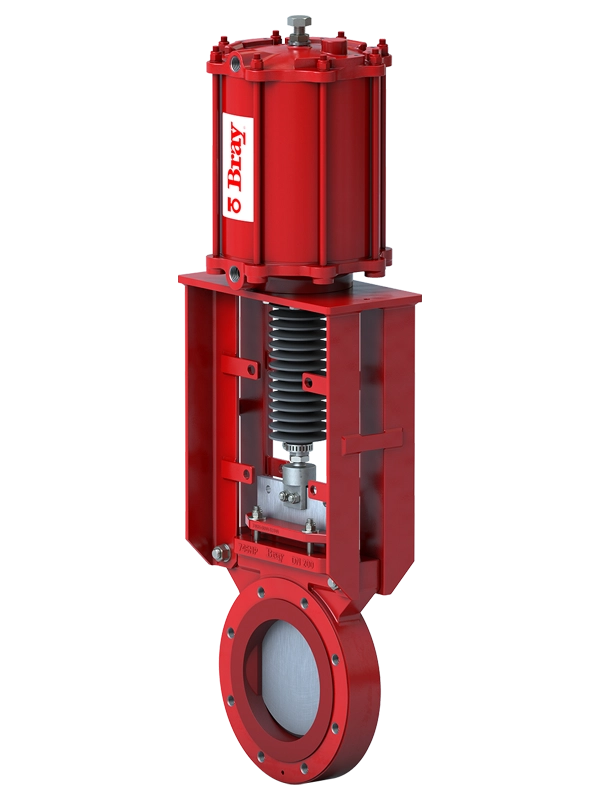

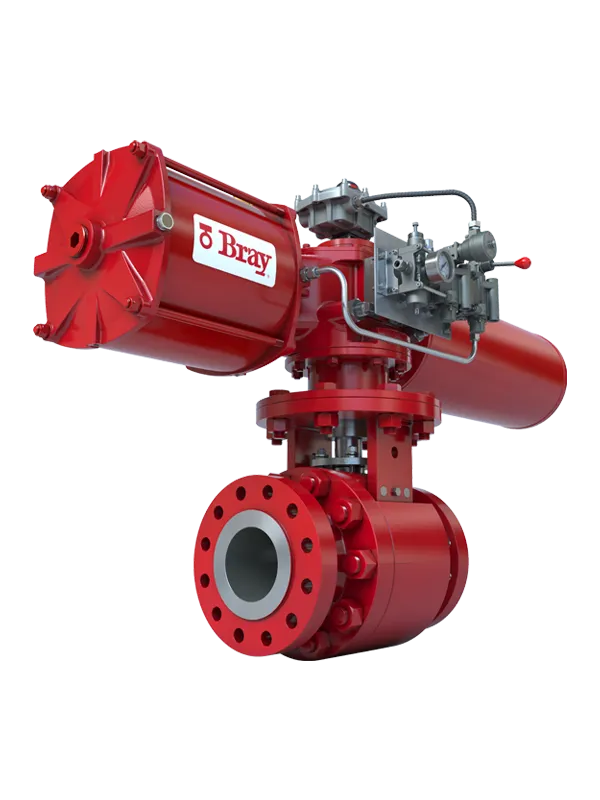

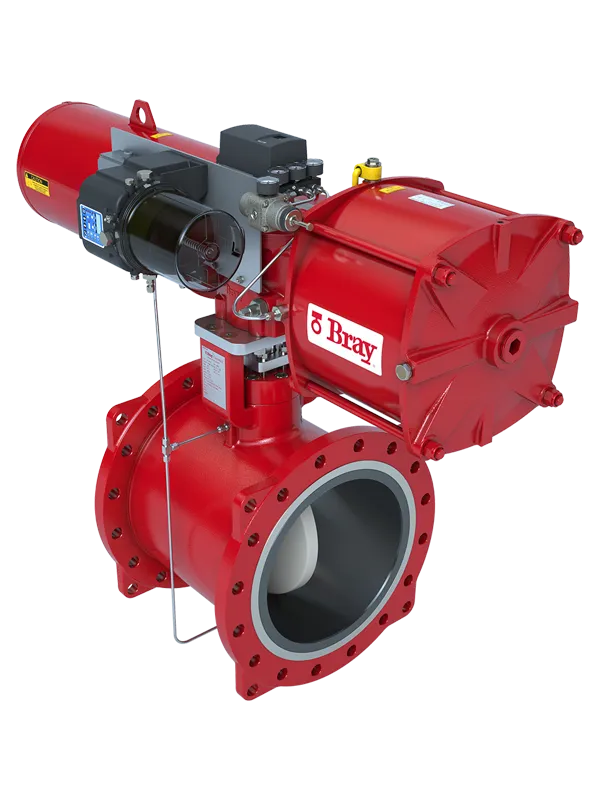

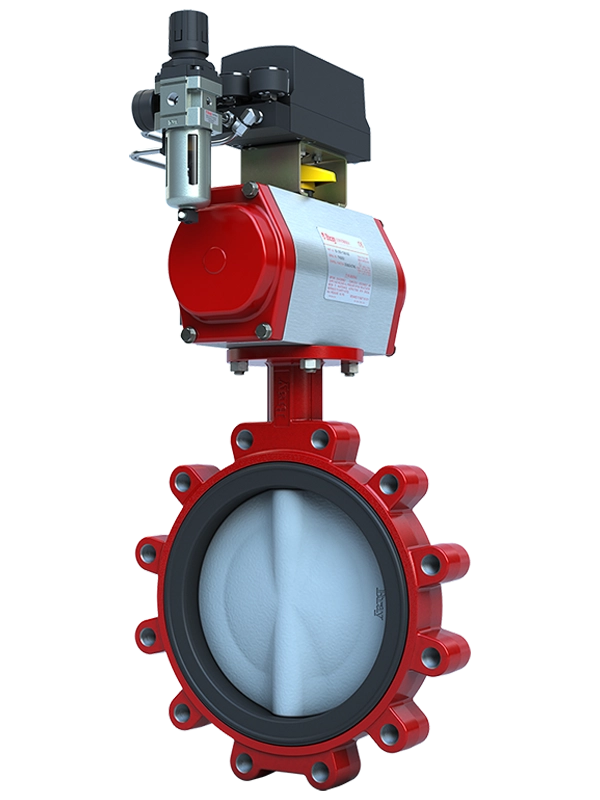

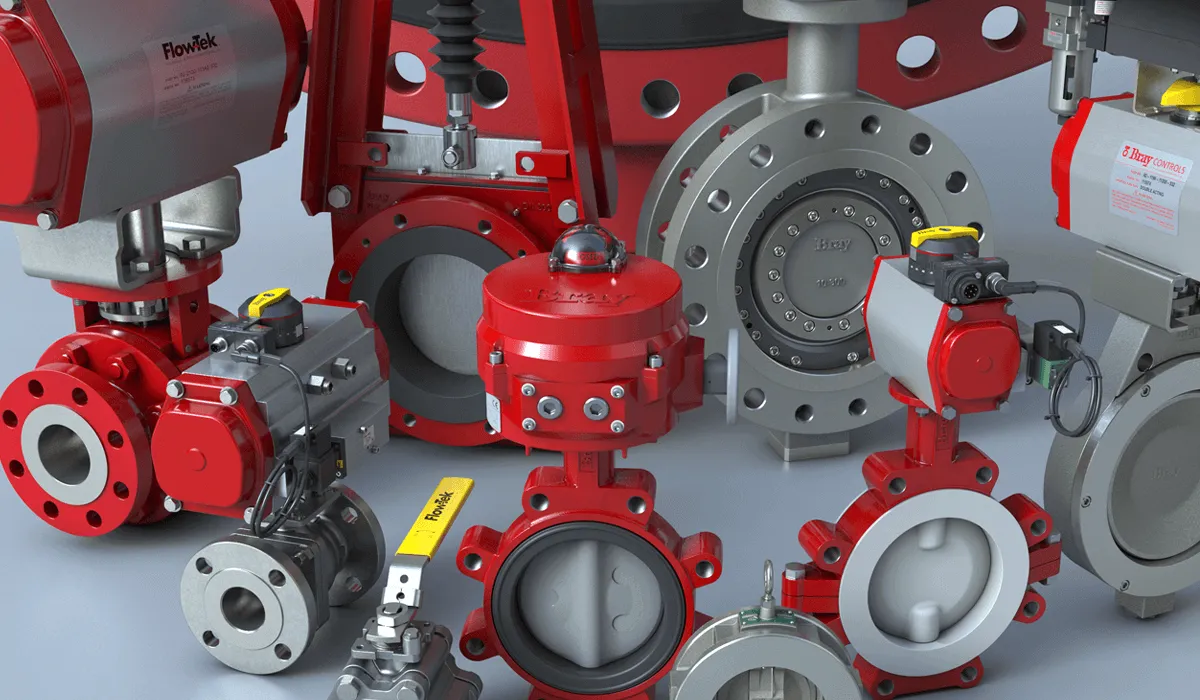

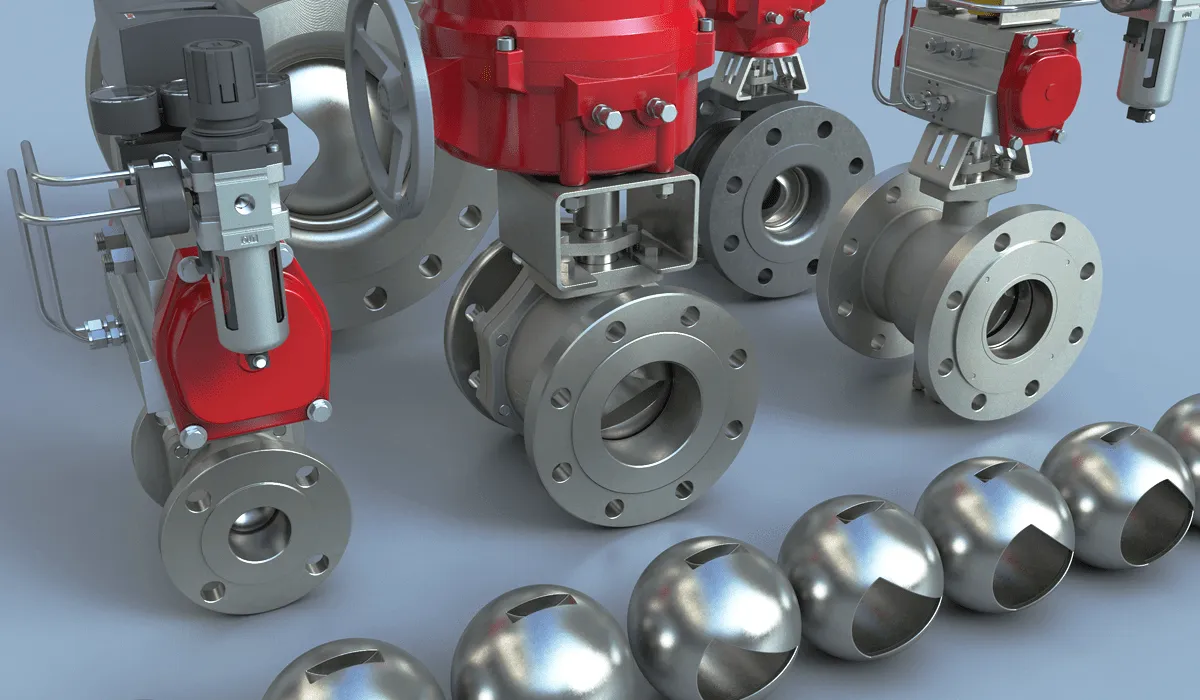

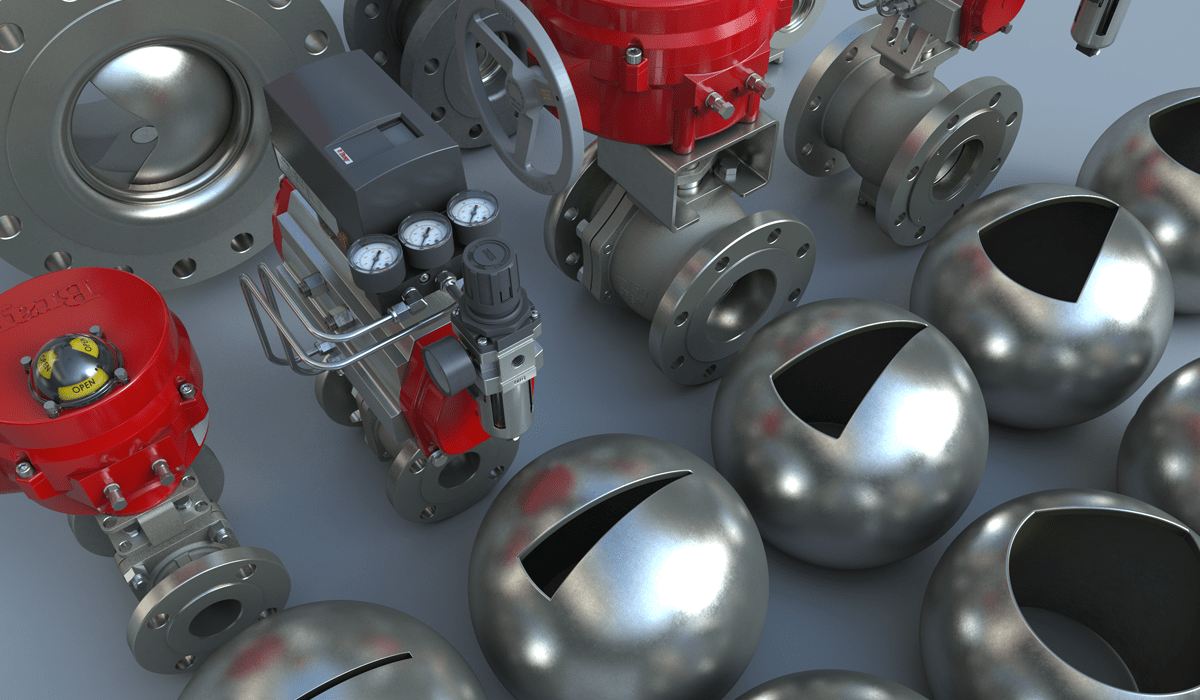

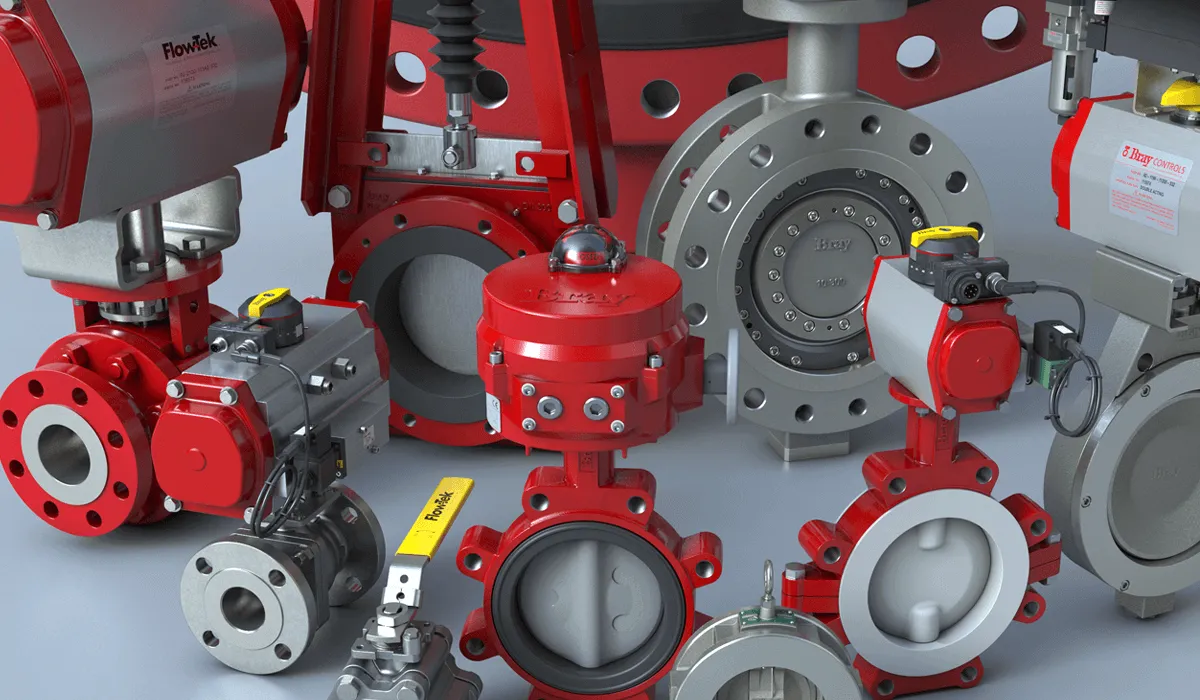

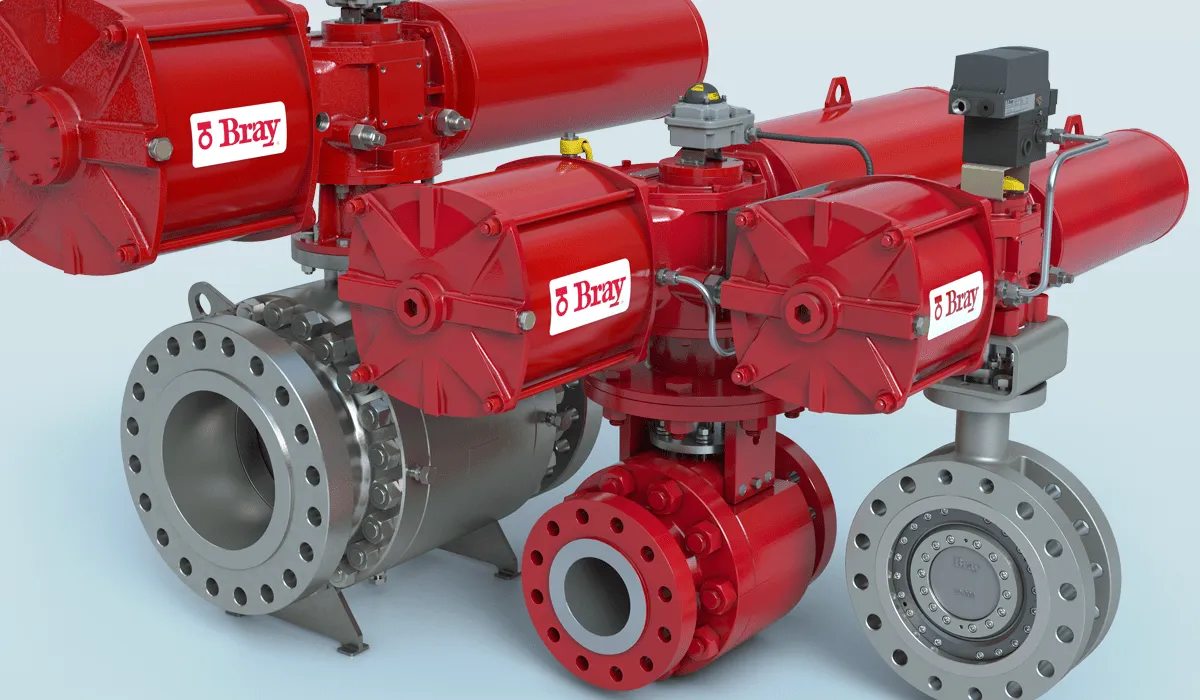

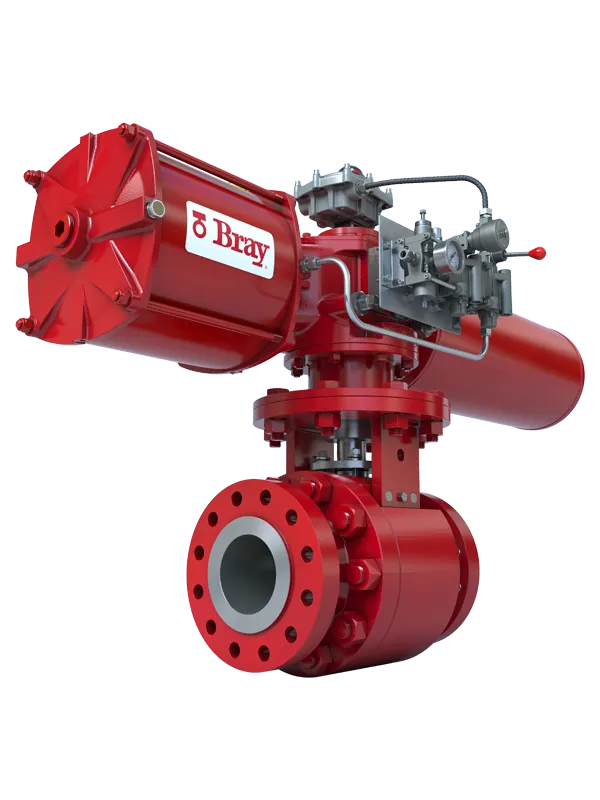

Verbessern der Armaturenzuverlässigkeit – Auswahl von Kugelhähnen für kritische Anwendungen

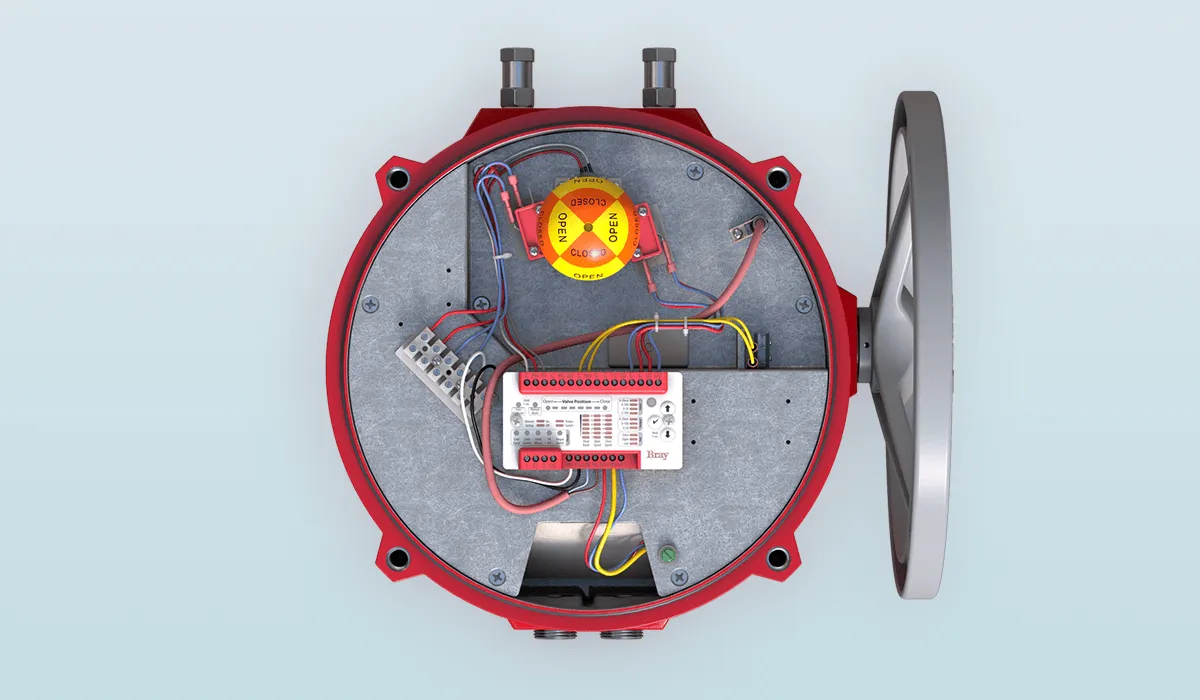

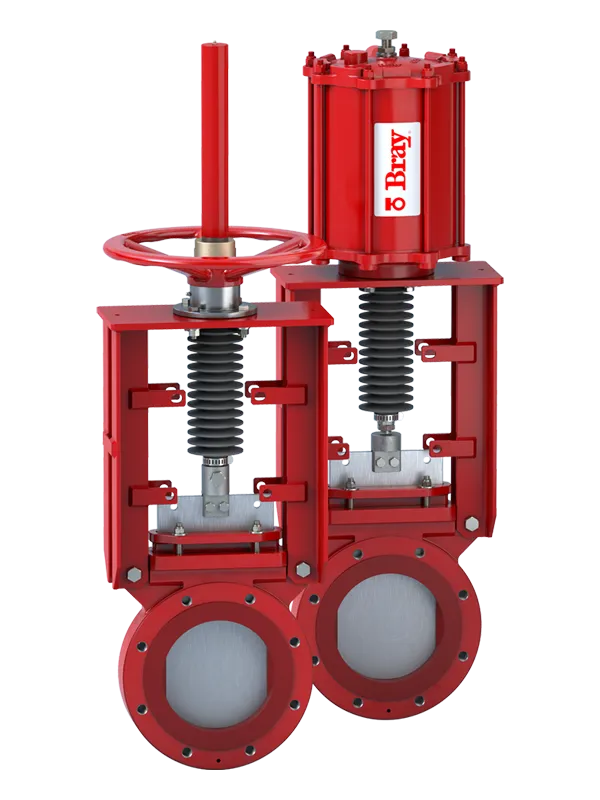

Verbessern der Armaturenzuverlässigkeit – Es fängt bei der Konstruktion an

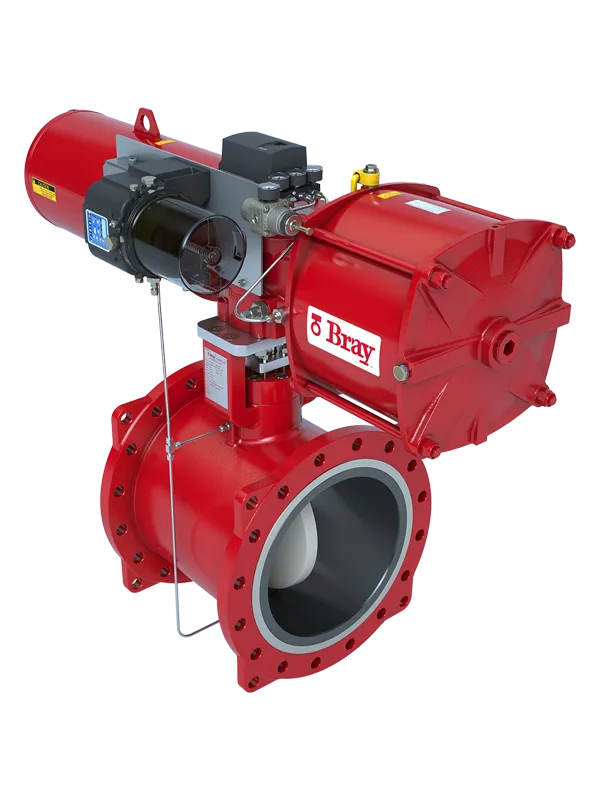

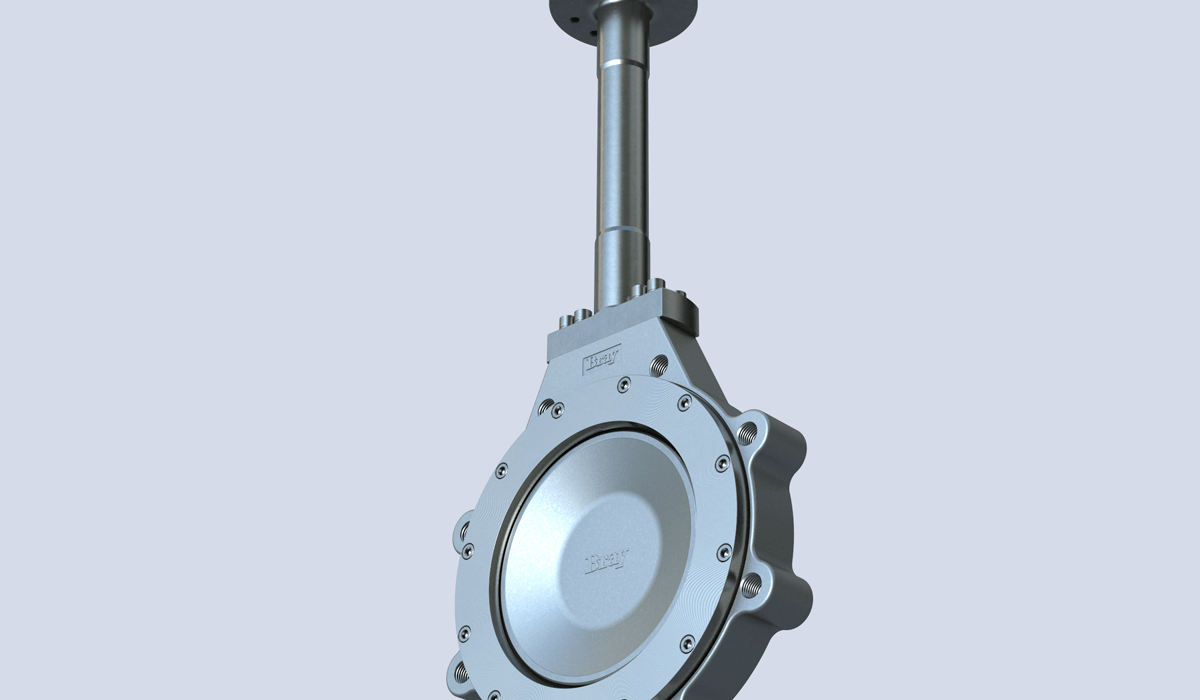

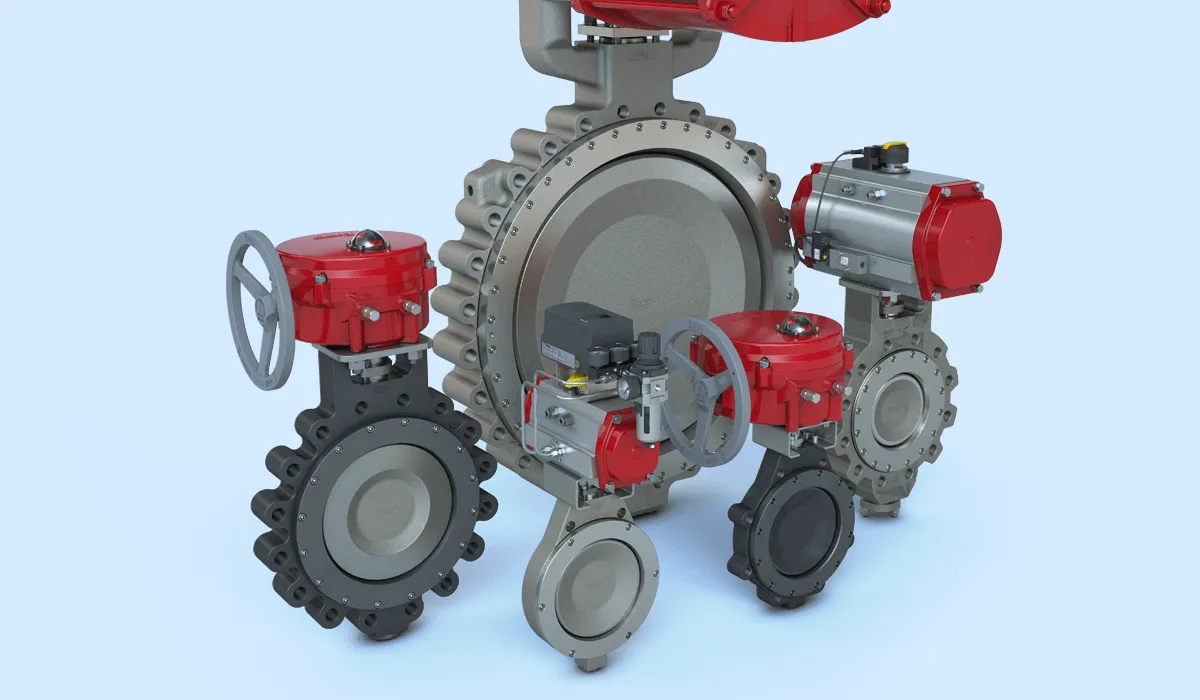

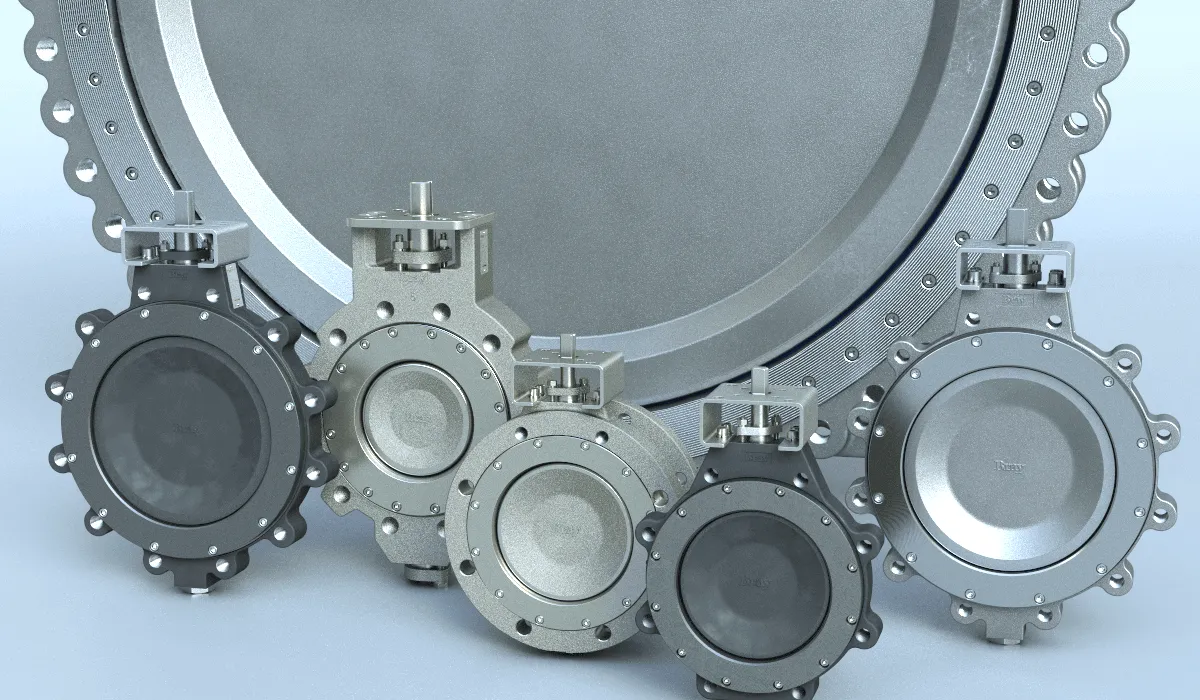

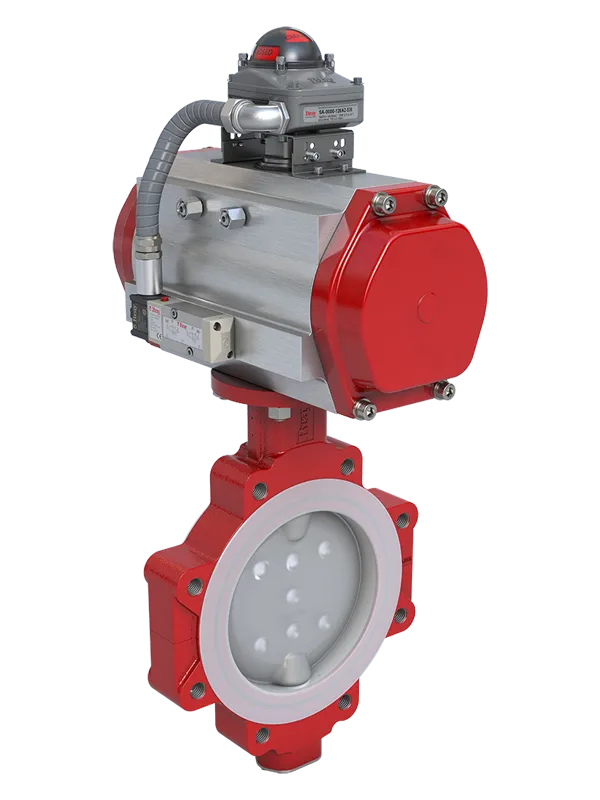

Verbessern der Armaturenzuverlässigkeit – Auswahl von Absperrklappen und Kugelhähnen

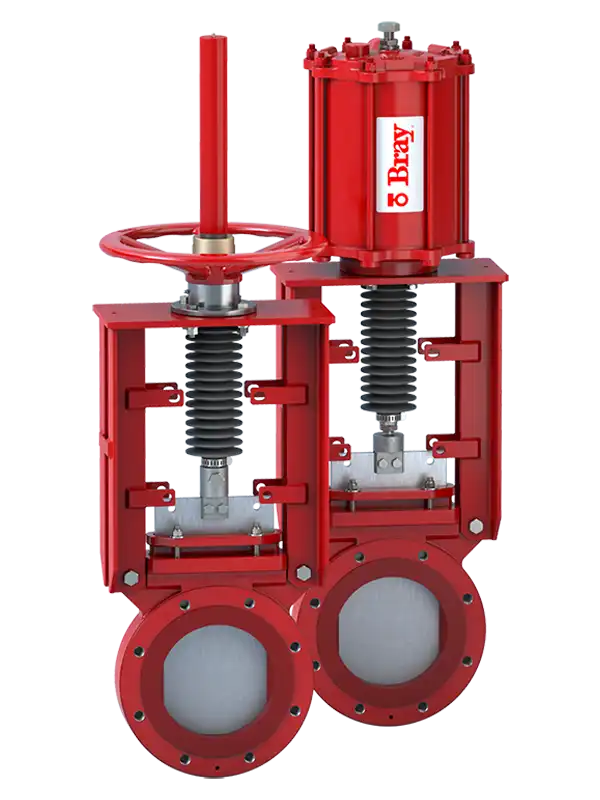

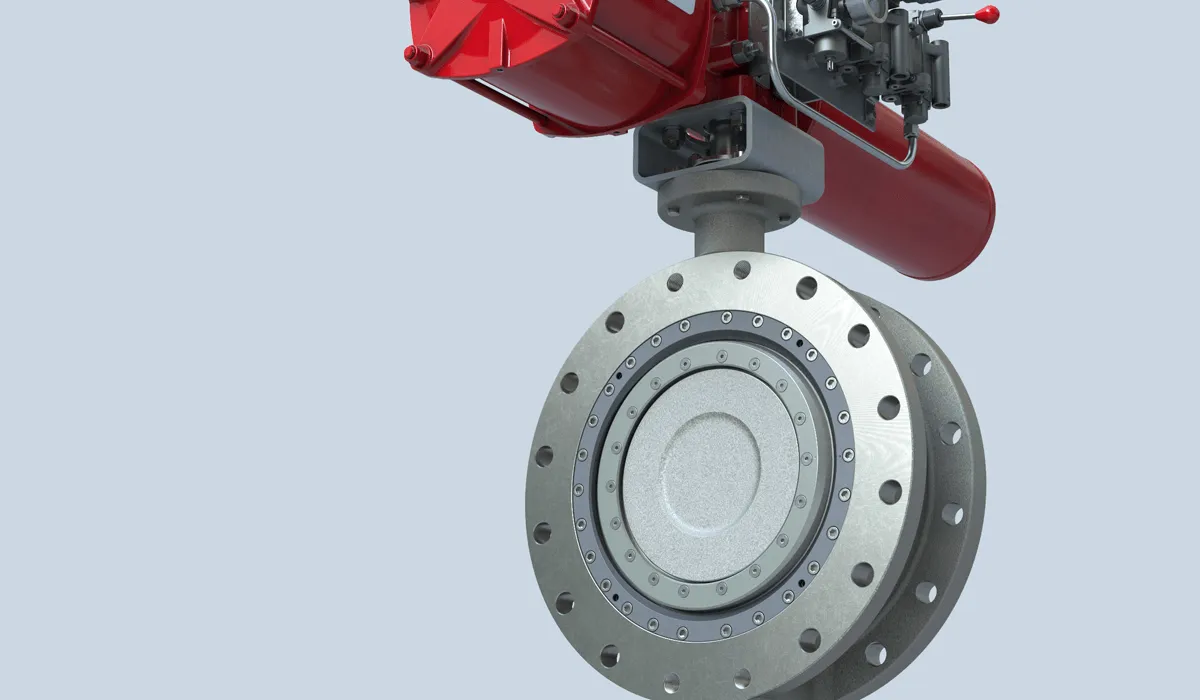

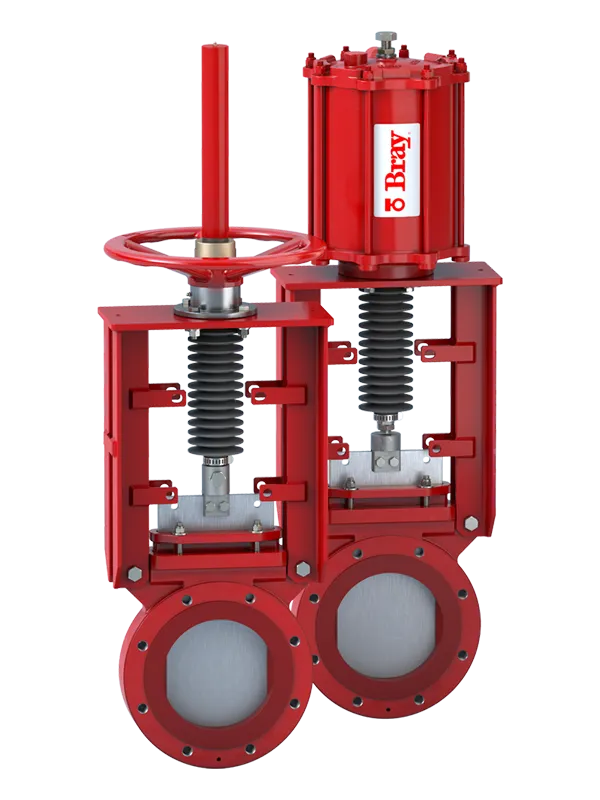

Erhöhung der Zuverlässigkeit für schnell wirkende Notabschaltventile

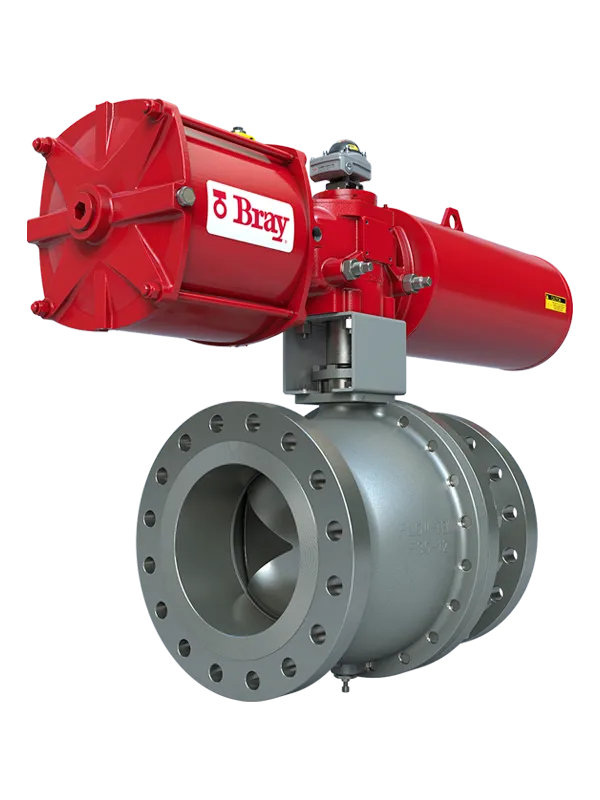

Unabhängige Bewertungen heben die Vorteile von Bray McCannalok hervor

-copy.webp)

-copy.webp)

.webp)