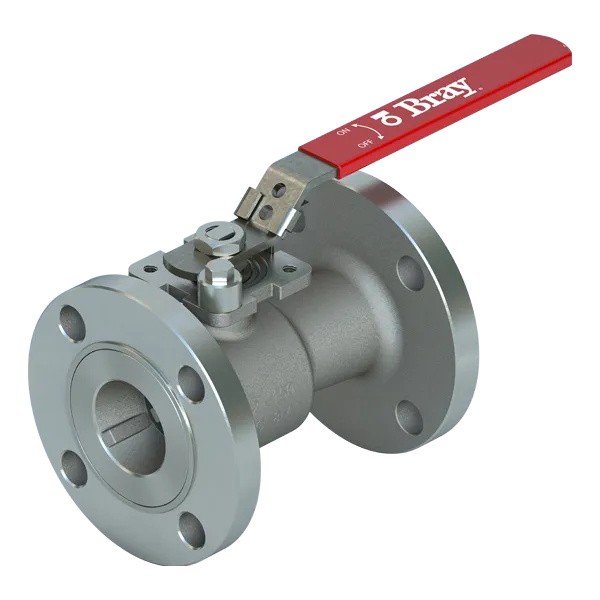

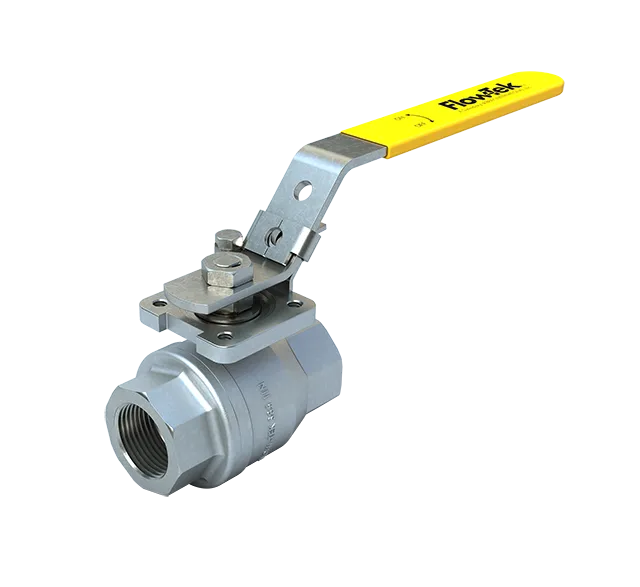

Vents & Drain Valves

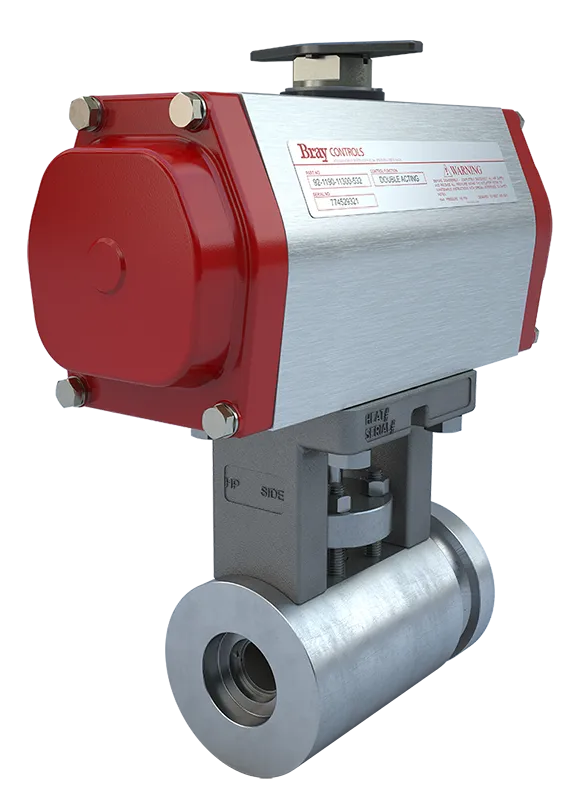

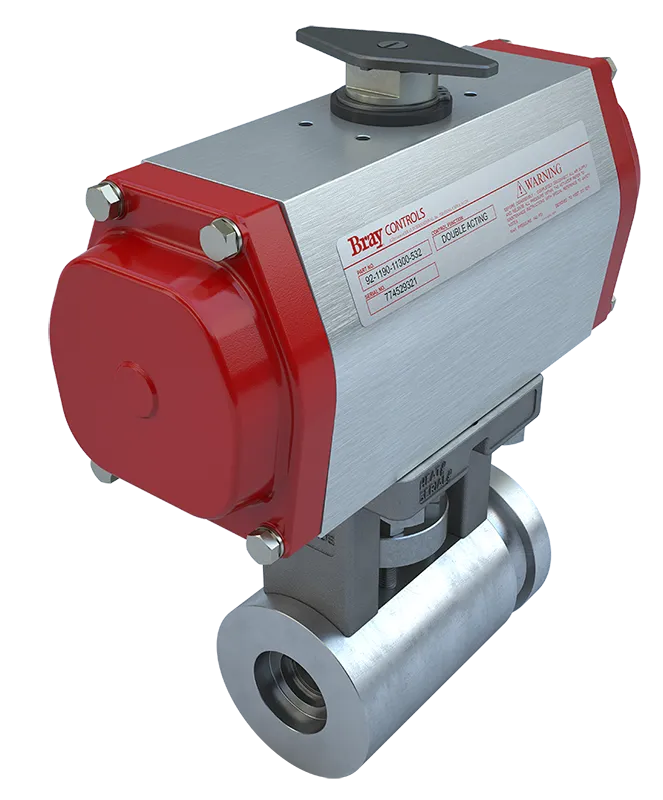

The Series M4 Severe Service ball valves are engineered specifically for Isolation in Vents & Drains Valve applications in the power industry. Series M4 valves are rigorously tested for dependable zero leakage on/off applications in high pressure, high temperature steam and superheated steam. Series M4 Vent & Drain Valves ensure maintenance free operation in the most extreme conditions.

Bray® Series M4 severe service ball valves are ideal for service in conventional coal and combined cycle power generation, Nuclear balance of plant applications, Co-Generation, for boiler drains, feedwater drains, header drains, turbine drains, above and below seat drains, superheater vents and drains, steam drum vents, sootblower isolation, bypass line isolation and economizer header drain applications as well as specialized applications including, power operated pressure relief valves, sky vents and special applications upon request.

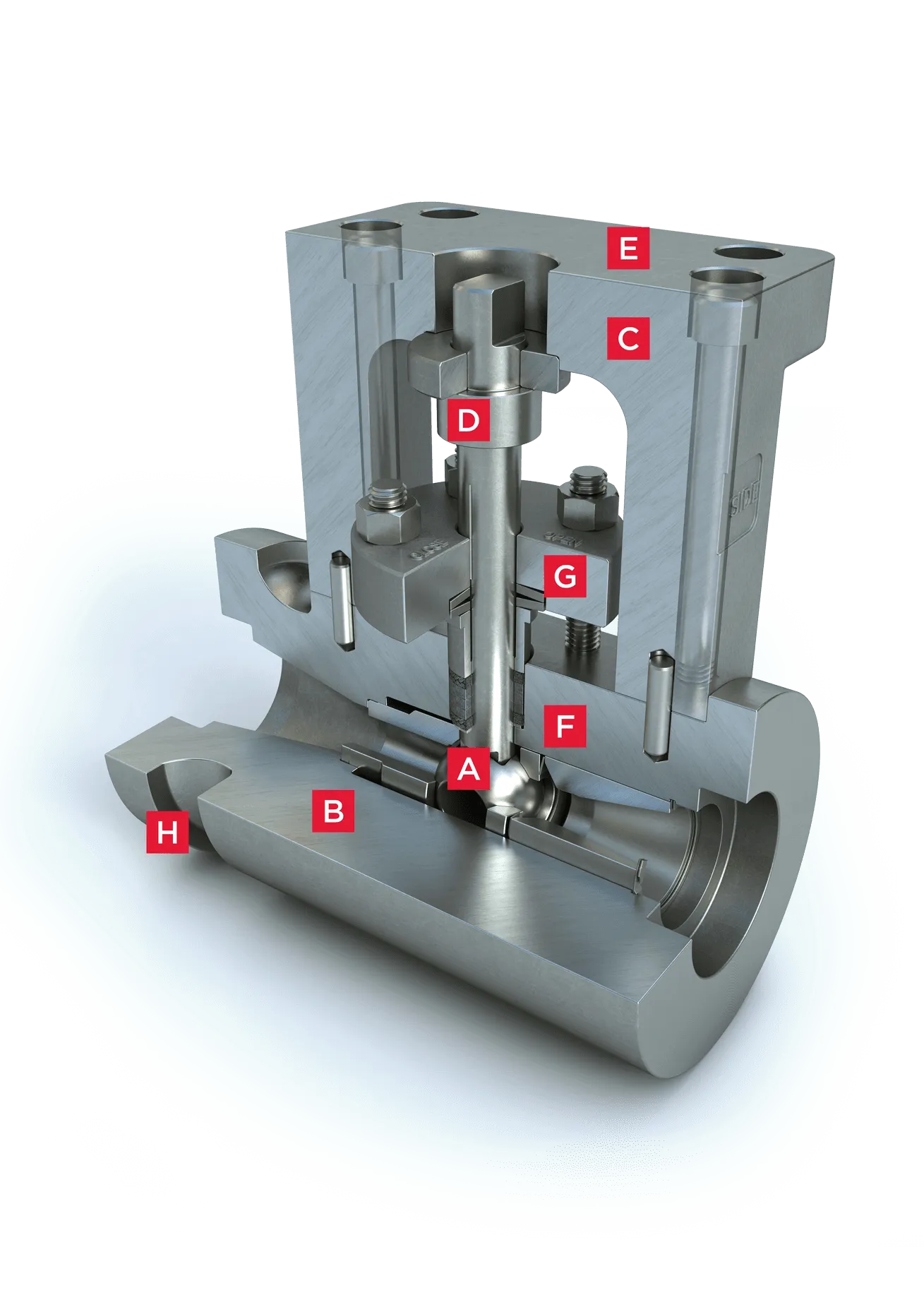

Series M4 severe service ball valves are engineered using advanced technology, featuring a 1-piece unibody body construction, with heavy-duty drivetrain, 360° mate-Lapped ball and seat with high velocity oxygen fuel (HVOF) and spray & fuse hard coating options along and live-load packing with Belleville springs. The ball and seats are constructed with the same materials and coatings, ensuring reliable tight shutoff and low seat stress during thermal cycling due to the parts shared thermal expansion rates, ensuring maintenance free operation, even in high-cycle service applications.

Series M4 Valves are manufactured in our ISO 9001:2015 facility with full traceability, including MTR’s, and certified to the requirements of Annex III, Module H of PED 97/23/EC, TSG, CRN and available compliance with TDP-1. M4 products are in stock and available for quick delivery worldwide to support MRO, turnarounds and planned maintenance intervals as wells as new plant construction projects.

Quality, Safety & Certification

- Zero Leakage is defined as no detectable or visible leakage of gas or liquid for a period of three minutes or greater.

- Our facilities have achieved ISO 9001:2008 for the design and manufacture of severe service valves.

- All pressure containing components are fully traceable.