Bray solutions for

Sugar Processing

Sugar processing conditions require valves capable of handling steam, caustic chemicals, dirty/viscous media, solid sugar crystals and erosive slurry found in sugar processing. Bray valve solutions for sugar processing are manufactured to ensure high reliability, uptime, and long service life throughout the Sugar production season. Our valves are designed for the entire sugar production process starting with juice extraction, filtration, clarification, evaporation, crystallization, centrifuge and refining processes. Bray valves are optimized for the entire sugar production process.

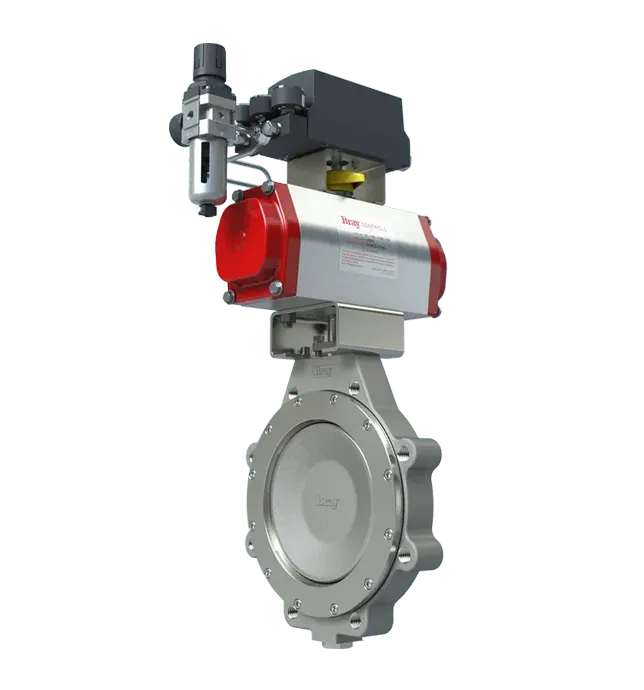

Bray Butterfly valves for

Sugar Production

Bray’s resilient seated butterfly valve are uniquely designed and suited for reliable performance in various parts of the sugar refinery requiring ZERO leakage at high cycle services such as juice heaters, vacuum pans and centrifuges. Bray high performance valve are specially designed for the Sugar Industry. These valves are structured to handle a wide range of media from slurry mud, to high temperature condensate and steam isolation & control applications. Bray Butterfly Valves ensure ZERO leakage performance, ease of field maintenance and low-cost automation.

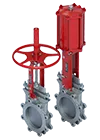

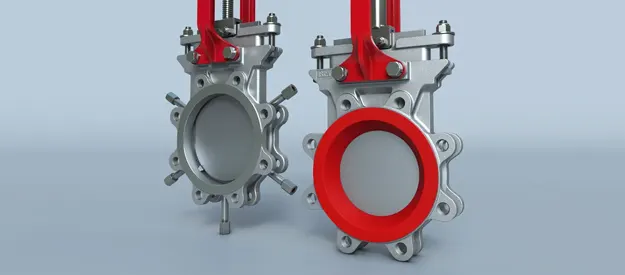

Bray Knife Gate valves for

Sugar Industry

In addition to standard knife gate valve solutions Bray has designed unique solutions to enhance the service life of valves in tough sugar industry applications. Options include purge ports which can be used to flush media in applications such as receivers/crystallizers where the media tends to dewater, solidify or build up in the seat area. Deflection cones on Bray knife gate valves can be used to redirect flow of suspended solid sugar crystals away from the seat towards the center of the bore. This extends service life of the seat and gate, ensuring uninterrupted service for the sugar Industry production season.

Bray Control Valves for

Sugar Refining

Bray Series S19/S19L segmented control valves are an ideal solution for precise control and dependable on/off service in the abrasive slurry control and clean media applications in sugar processing. Some of the key features include drive train protection to prevent ingress of media into the stem area to prevent jamming issues, seat and segment design provides self cleaning action preventing media build up in the valve internals, abrasion resistant coatings and liner to handle high velocity and highest level of abrasion in the sugar industry and on top of all these key features the valves are field maintainable with minimal spare parts. Bray also manufactures a wide array of Vball valves including 1 piece, 2 piece and 3 piece valves including flanged, threaded, and socket weld options for characterized control applications for water, steam and other process support in sugar processing and Sugar refining applications.

Dependable Automation Solutions for

Sugar Mills

Bray is a leader in valve automation providing innovative products and state-of-the-art technical solutions to our customers. Thru years of closely working with our customers and a robust technology organization the Bray portfolio has evolved to provide a complete range of actuators, positioners, switches, sensors and accessories for various applications in multiple industries. From smart intelligent positioners and IIoT enabled sensors/switchboxes to Ethernet plug and play electric actuators and hydraulic actuators, Bray provides a wide range of high performing products to maximize customer uptime, safety and efficiency. That’s why customers around the world rely on Bray products to keep their processes running.

Certified and Trusted

By thousands of companies worldwide

Our performance tested products are in compliance with a variety of global certifications and approvals, including Lloyd's Register, UL, ABS and more.

-copy.webp)

Sugar Cane

Virtual Plant

Discover how Bray's valves optimize sugar processing. Access technical info, connect with experts, and explore key applications.

Sugar Beet

Virtual Plant

Experience Bray’s solutions in action and explore how they optimize each stage of the sugar beet process.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business