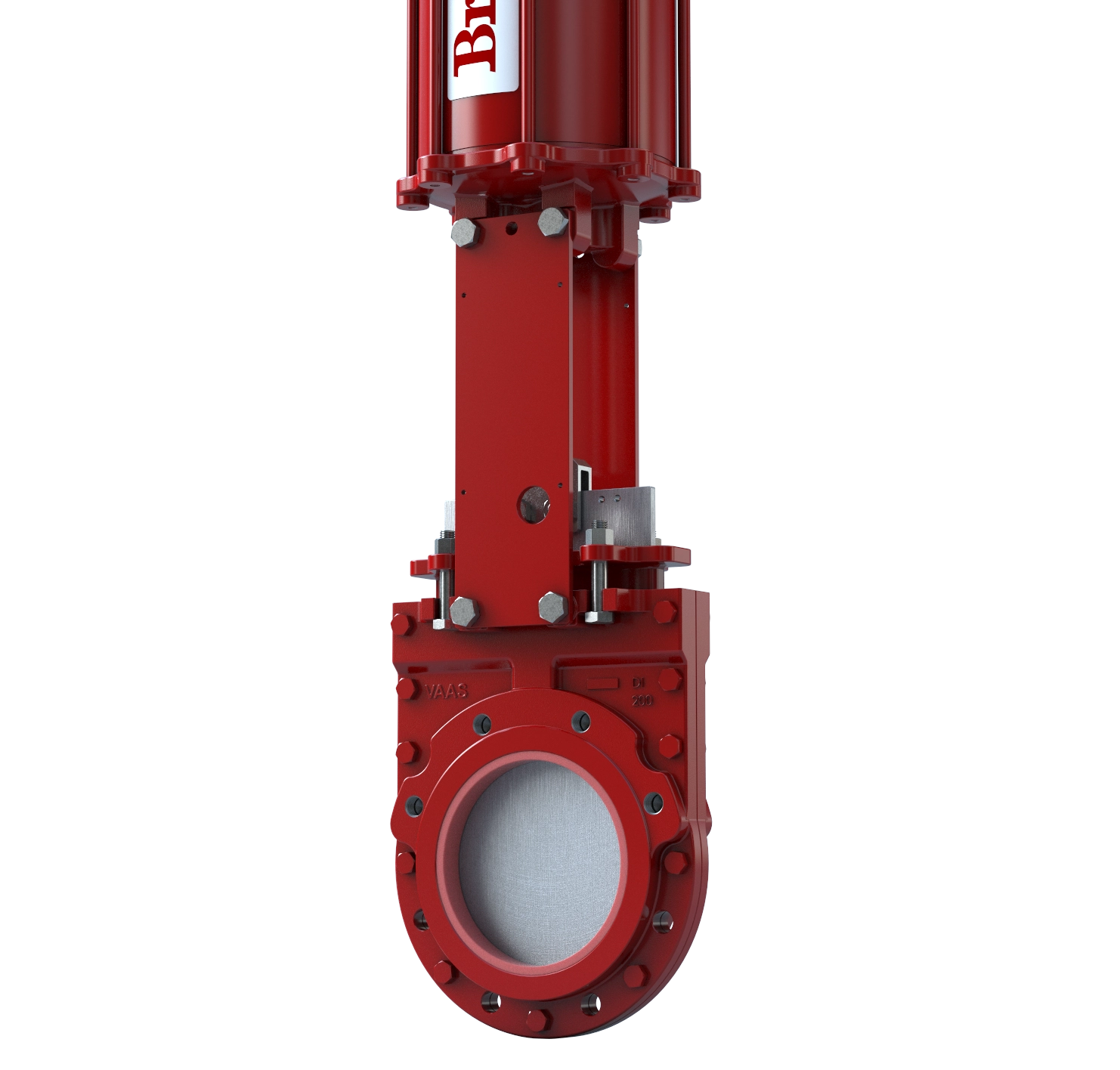

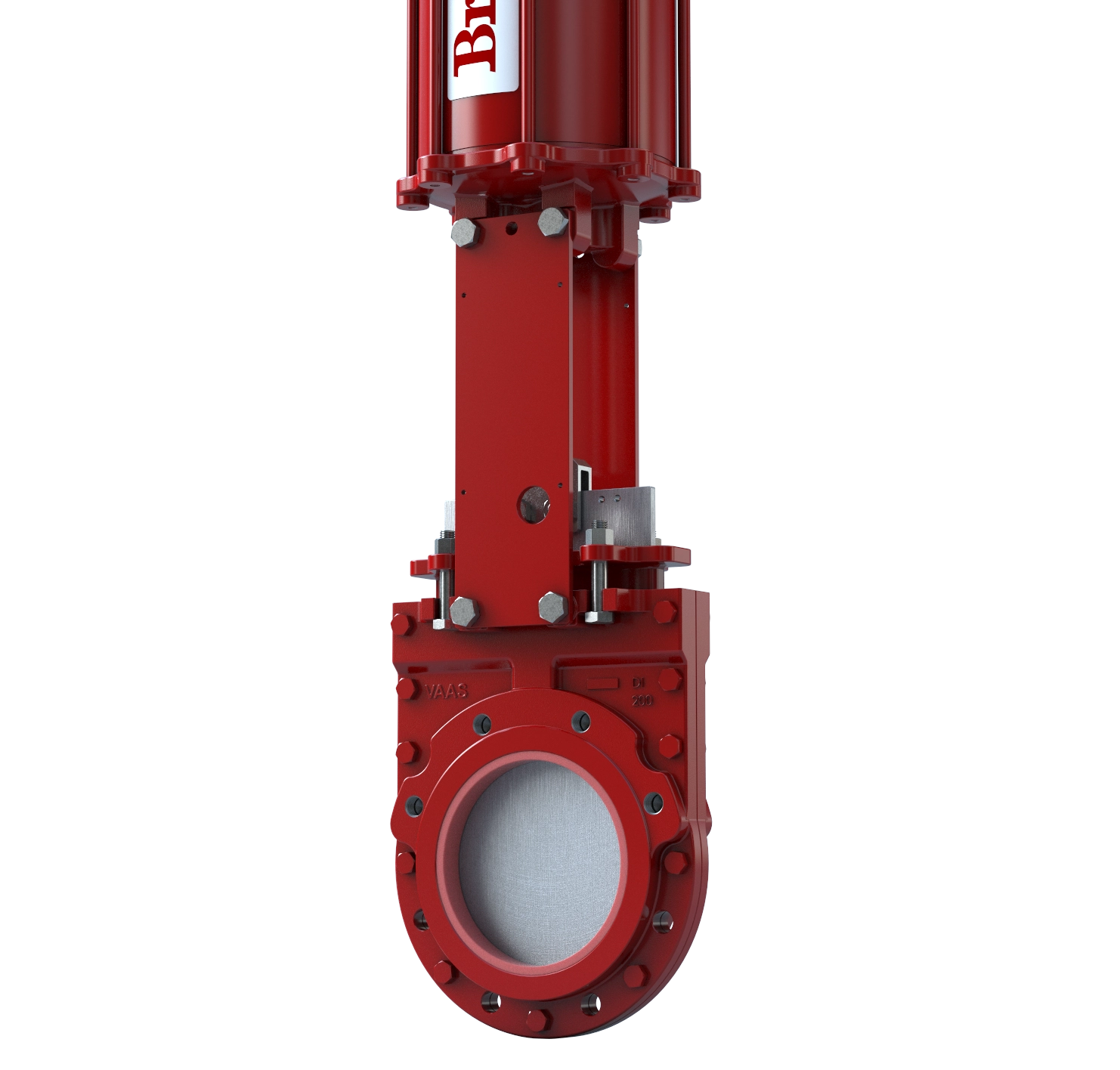

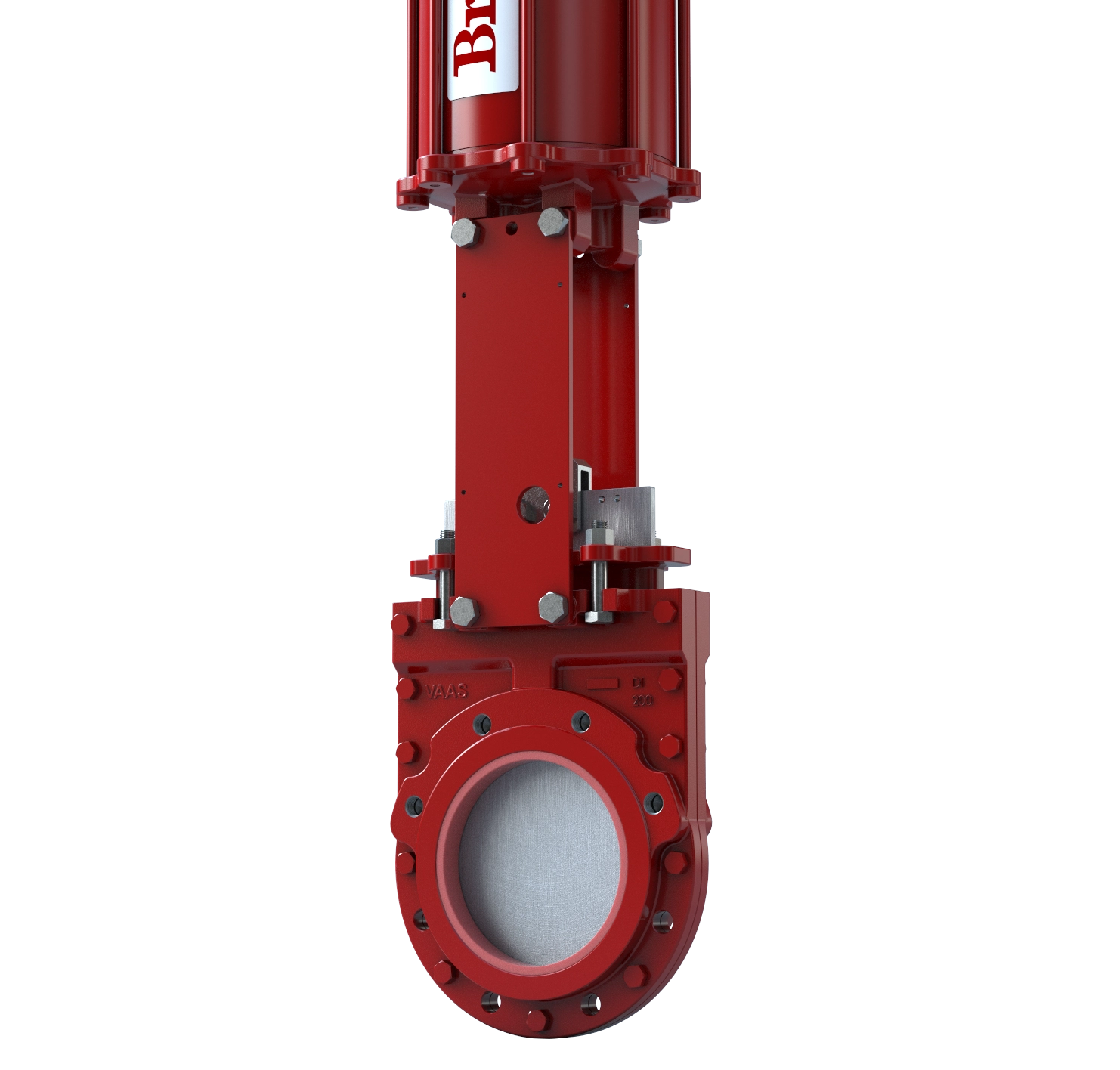

Bidirectional Knife Gate Valve

Series 755

Durable Bidirectional Valve with Field-Replaceable Liner for Abrasive Industrial Applications

Corrosion-Resistant Materials for Versatile Industrial Use

Engineered Durability for Corrosive Industrial Applications

The Bray Series 755 Bidirectional Knife Gate Valve is engineered to excel in managing abrasive and corrosive slurries across diverse applications, focusing on performance and reliability. Its design and robust construction set a new standard for efficiency and durability in industrial environments.Featuring a robust two-piece bolted body configuration, the Series 755 valve ensures structural integrity and simplifies maintenance procedures, enhancing operational efficiency. Similar to the Series 752, the valve utilizes a steel-reinforced molded perimeter seat to achieve zero-leakage bidirectional closure.With sizes ranging from 2" to 24" (50 - 600 mm), the 755 Series offers flexibility to address various application demands. It effortlessly withstands high-pressure environments with pressure rating up to 240 psi (16 bar).To meet specific application requirements, the 755 Series knife gate valve offers a variety of body material options, including CF3M stainless steel, SAF 2205 Duplex, and SAF 2507 Duplex for use in corrosive applications. Furthermore, the Series 755 knife gate valve features a field-replaceable polyurethane bore liner, enhancing performance and providing a cost-effective solution for abrasive applications.

Specifications

Size Range

NPS 2 to 24 / DN 60 to 600

Body Materials

Ductile Iron, Carbon Steel (WCB) CF8 Stainless Steel, CF8M Stainless Steel, CF3M Stainless Steel

Maximum Allowable Operating Pressure

240psi (16bar)

Stem Materials

304 Stainless Steel

Body Style

Wafer, Two-Piece Bolted

Gate Materials

304, 316, 317 Stainless Steel, SAF 2507, SAF 2205,17-4PH, Hastelloy® C, Monel®

Seat Material Temperature Range

Buna-N: -34 to 194°F (-36 to 90°C)

EPDM: -65 to 248°F (-54 to 120°C)

Viton®: -15 to 392°F (-26 to 200°C)

EPDM: -65 to 248°F (-54 to 120°C)

Viton®: -15 to 392°F (-26 to 200°C)

Design Standard

MSS SP81

Packing Maximum Temperature

PTFE/Buna-N: 194°F (90°C)

PTFE/Viton®: 392°F (200°C)

PTFE/EPDM: 248°F (120°C)

PTFE/Viton®: 392°F (200°C)

PTFE/EPDM: 248°F (120°C)

Testing Standard

MSS SP151

Liner Maximum Temperature

176°F (80°C)

Certifications

ATEX, CRN, PED, PE(S)R, TR CU, UA TR

Face to Face

MSS SP81

Actuator Options

Handwheel, Bevel Gear, Pneumatic, Hydraulic, Electric

More Details

Features & Benefits

- Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance

- Clevis design and horizontal bolting stabilizes gate ensuring proper alignment

- Standard multi-layer square packing provides exceptional gland sealing

- Optional energized quad seal packing for enhanced gland sealing

- Unrestricted flow path with minimal pressure drop achieved through full port valve design

- Replaceable steel reinforced elastomer perimeter seat ensures bidirectional zero leakage shutoff

- Two piece bolted body for easy maintenance and seat replacement

- Polyurethane liner bonded to both halves of the body (755P) completely protect valve body from media

- Polyurethane bore liner provides total protection from abrasive media

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

Dependable Valve Solutions for Power Plants by Bray

Power Industry

Bray provides reliable valves and actuators for power generation plants, ensuring uptime.

Explore Our Power Valve Solutions

.webp)

.webp)