More Details

Features & Benefits

-

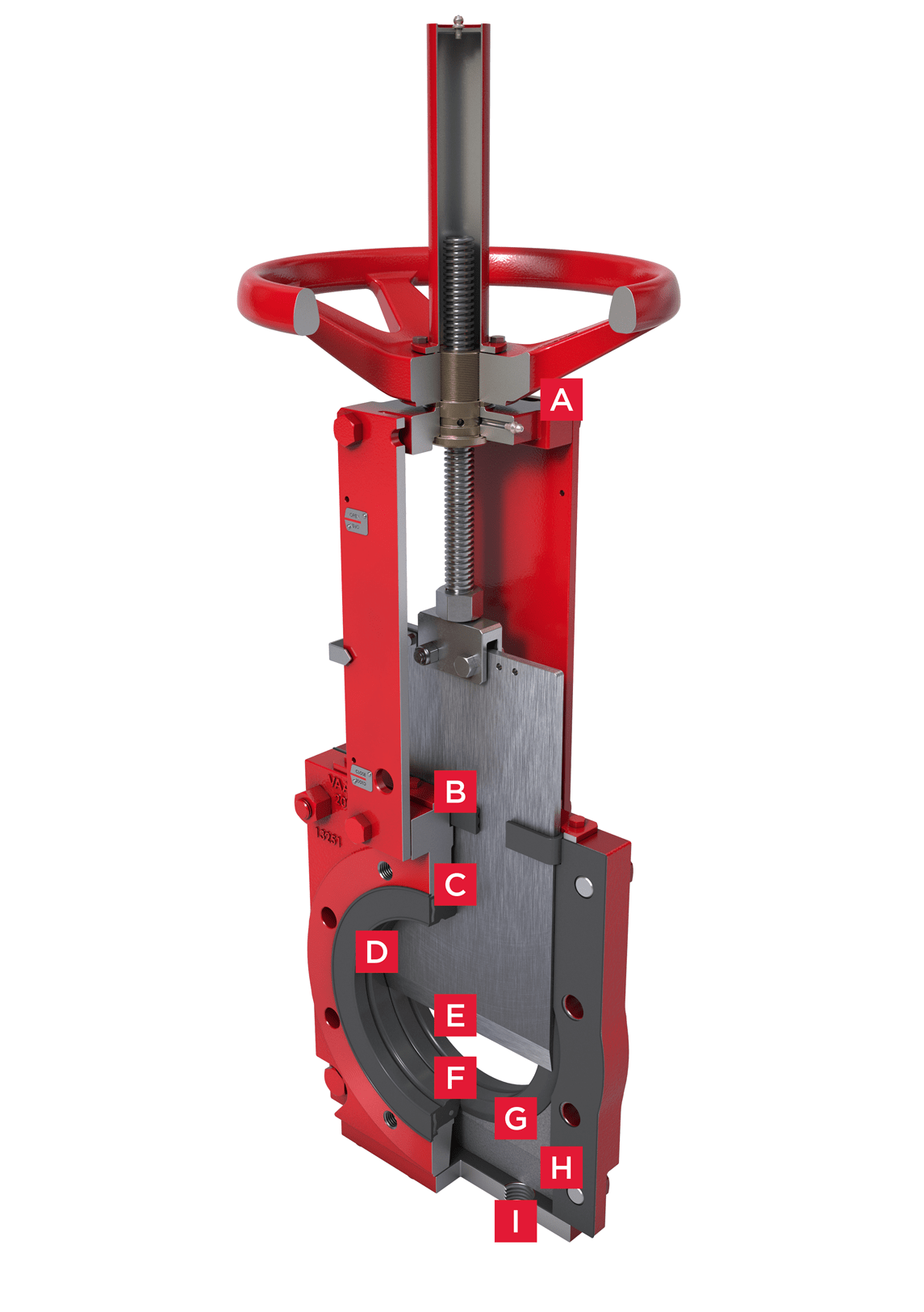

A - Topworks

Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance.*

-

B - Secondary Wiper Seal

Self-adjusting secondary wiper seal extends gate life and prevents discharge from top of valve.

-

C - Elastomer Sleeve

Metal-reinforced, elastomer sleeves provide energized, zero leakage shutoff in both directions.

-

D - Energized Sleeve

In the open position, the energized sleeves shield all metal components from direct contact with the flowing process media.

-

E - Robust Gate

Robust gate available in a wide range of corrosion resistant alloys to suit the application.

-

F - Unrestricted Flow Path

Unrestricted flow path with minimal pressure drop achieved through full port valve design for extended sleeve life.

-

G - Complete Gate Closure

Ample clearance for push-through allows complete gate closure.

-

H - Compact Wafer Body

Compact wafer body allows for easy installation and is drilled and tapped to ASME CL150 flange patterns as standard. Other drilling options available upon request.

-

I - Drain Plate with Purge Ports (Optional)

Drain plate with tapped purge ports offered as an option, allowing for safe discharge of media and easy flush water connection.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

.webp)

.webp)

-copy.webp)