More Details

Features & Benefits

-

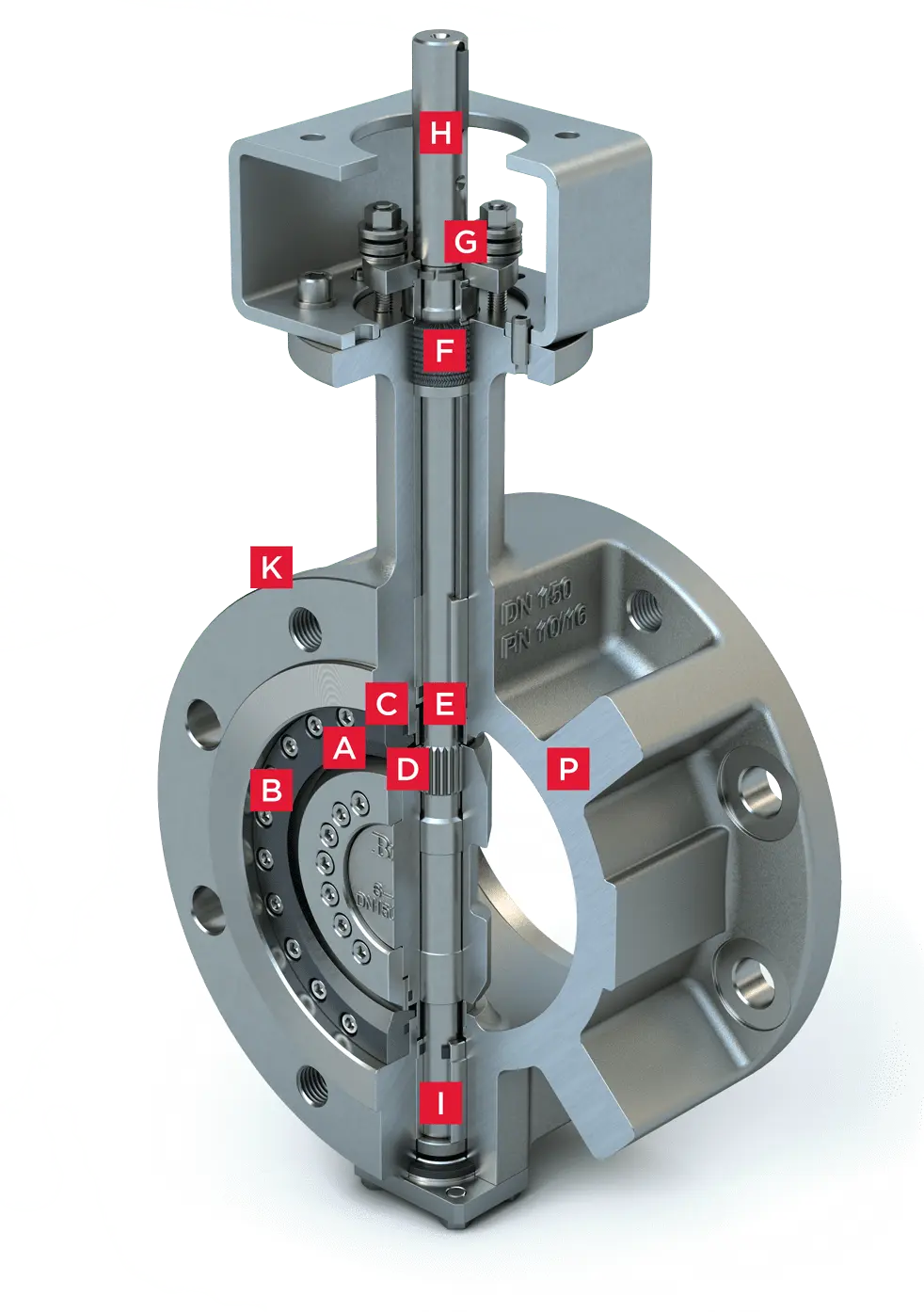

A. Seat & Seal System

The fully field-replaceable seat & seal extends overall life, minimizes downtime, and reduces the need for costly off-site repairs or total replacement.

-

B. Enhanced Seat Hardness

Eliminates risk of seat/seal galling, offering superior performance, durability, and abrasion resistance compared to other materials.

-

C. Sealing System

The non-rubbing, metal-to-metal sealing system is inherently firesafe and fire-tested, while meeting zero-leakage requirements for many critical applications.

-

D. Seal Ring

Offers a flexible design and wide range of materials to provide torque-loaded sealing with zeroleakage. (Optional solid seal ring available.)

-

E. Splined Disc-to-Stem Connection

The strong and reliable connection allows for axial movement of the stem independent of the disc, to protect the disc/stem connection from temperature fluctuations and pressure effects. This connection prevents typical misalignment problems of rigidly attached discs and stems, minimizes hysteresis, eliminates external connections & associated hardware, and allows for easy assembly & disassembly.

-

F. Stem Packing

Fully-adjustable, field-replaceable stem packing is certified to international fugitive emission standards.

-

G. Blowout-Proof Stem

One-piece stem features blowout prevention ring located outside of the pressure boundary, as well as redundant blowout prevention mechanisms.

-

H. Indexed Stem

Provides positive visual indication of disc/seal ring position after installation.

-

I. Elongated Stem Bearings

Hardened bearings provide maximum stem support.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business