Ball Check Valves

Maxi-Check

High-Pressure, Low-Pressure, and Dual-Function Check/Isolation Models

Prevent Reverse Flow

Isolation Valves for High Pressure

Bray’s SlurryTuff™ brand includes the MAXI-CHECK line of ball check valves and ball check isolation valves. Available in high pressure high wear, low pressure &low wear and dual function check/isolation models. They are designed to prevent reverse flow, and in the case of the Model I, prevent reverse flow with isolation.

Specifications

Purpose

Non Return & Isolation

Type

Ball check & Ball check isolation

Size Range

DN 80 to DN 750 / NPS 3 to 30

Figures Available

MH0300 to MH2800

Rating

ANSI B16.5 Class 150/300/600 & 900 @ 65°C (150°F) Nominal

Ends

ASME B16.5, DIN

Body-Inlet

Fabricated carbon steel standard other materials on request

Body-outlet

Fabricated carbon steel standard other materials on request

Ball Materials

Urethane coated metal core

Seal

Moulded ntural rubber as required

Gasket

BS‐N90 90 shore O ring between body and outlet flange for high pressure seal

Fasteners

Carbon steel galvanised high tensile 8.8 standard or stainless steel on request

Face to Face

On request

Testing Standard

AS 4037-1999 / EN 12266 Pt 1 & 2 / API 598

applications

Slurry pipelines, Power plant ash disposal, Mine dewatering, Pipelines with scale, Cement plant, Pulp & paper, Water & wastewater, High pressure pipelines

Downloads

Product Brochure

Ball Check Valves / Isolation Valve Slurrytuff® Maxi-Check

Download

English

More Details

Features & Benefits

Engineered for slurry service, MAXI-CHECK operating features include:

- Full bore design: Provides unrestricted flow ensuring low pressure loss and minimum back pressure to seal

- Large port: Prevents clogging

- High-wear resistant seat and ball design: Offers large sealing area, to provide drip-tight sealing under all conditions

- Sinking ball design: Preferred for applications involving viscous liquids or slurries

- Self-cleaning: The ball rotates during operation eliminating the risk of impurities adhering to the ball

- Fabricated design: Low weight and allows for inline repairs

- Operation: suitable for horizontal or vertical application

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

Copper Mining, Mineral Processing, Refining & Production

Copper Mining

Bray valves, actuators, controls and accessories are engineered to deliver reliable service for copper mining, copper concentrates production, smelting and electrolysis around the world.

Explorer Now

Explore Bray's Innovative Solutions for Efficient, Reliable Operations in the Copper Mining Process

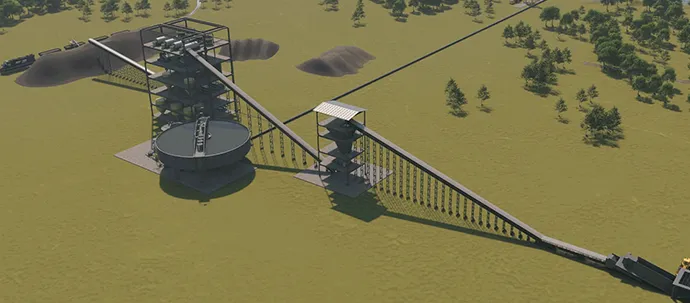

Coal Mining Virtual Plant

Explore our Virtual Coal Mining Plant and discover more about our Bray Solutions.

Copper Mining Industry Solutions

Optimized Valves for Metals & Mining

Solutions for Mining Industry

Our durable valves, actuators, and controls are built for challenging mining and refining processes, handling abrasive, corrosive chemicals in aluminum, copper, gold, and more.

Explore Our Mining Products-copy.webp)