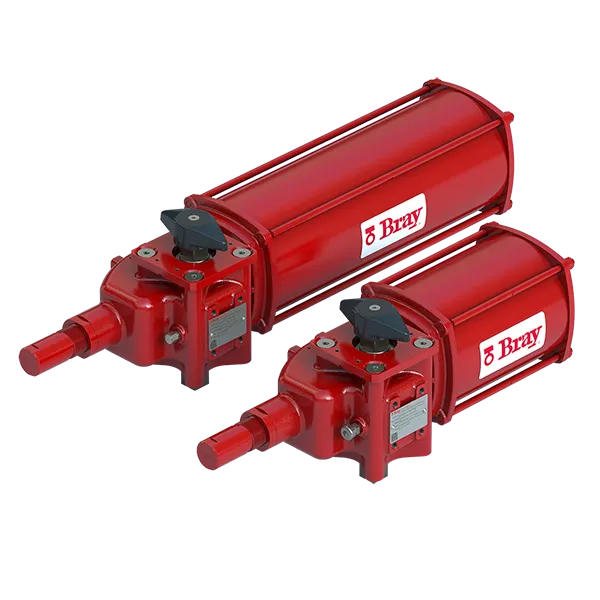

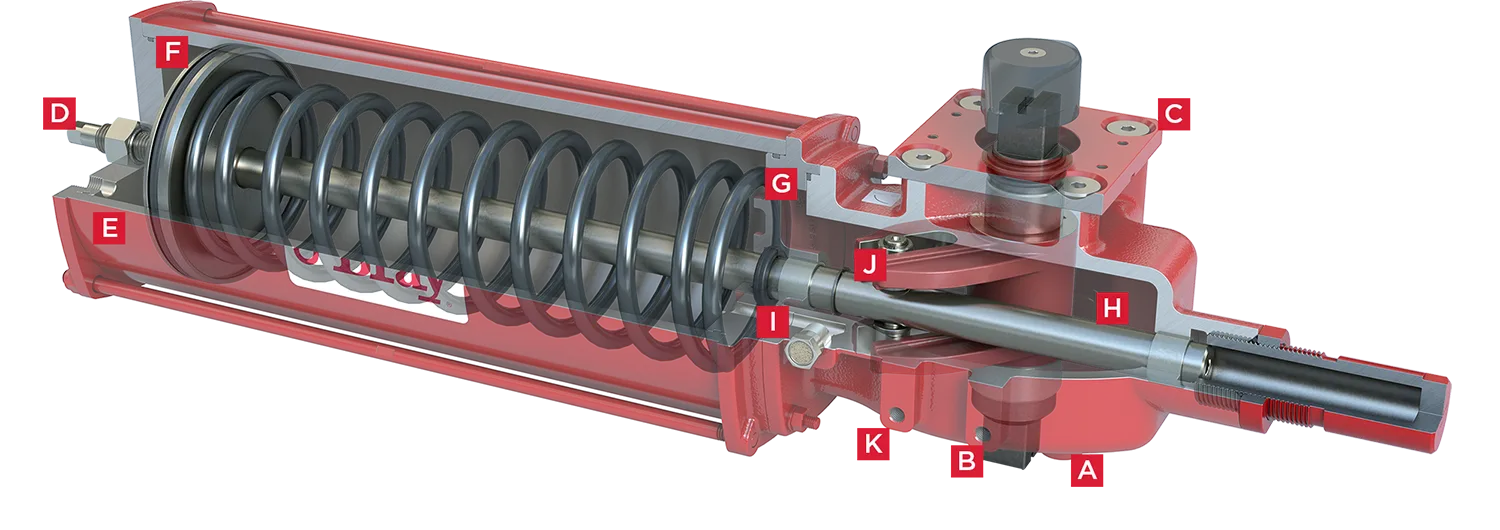

The compact Series 98C Scotch Yoke Actuator continues Bray’s commitment to provide products which exceed customers demanding applications. By utilizing proven technologies of the larger Series 98 scotch yoke actuator, the Series 98C, tested to withstand up to 1,000,000 cycles, offers a range of compact scotch yoke actuators with torque outputs up to 17,701 lbf-in (2,000 Nm). This torque range easily covers common rotary turn valve sizes from 2” to 20”.

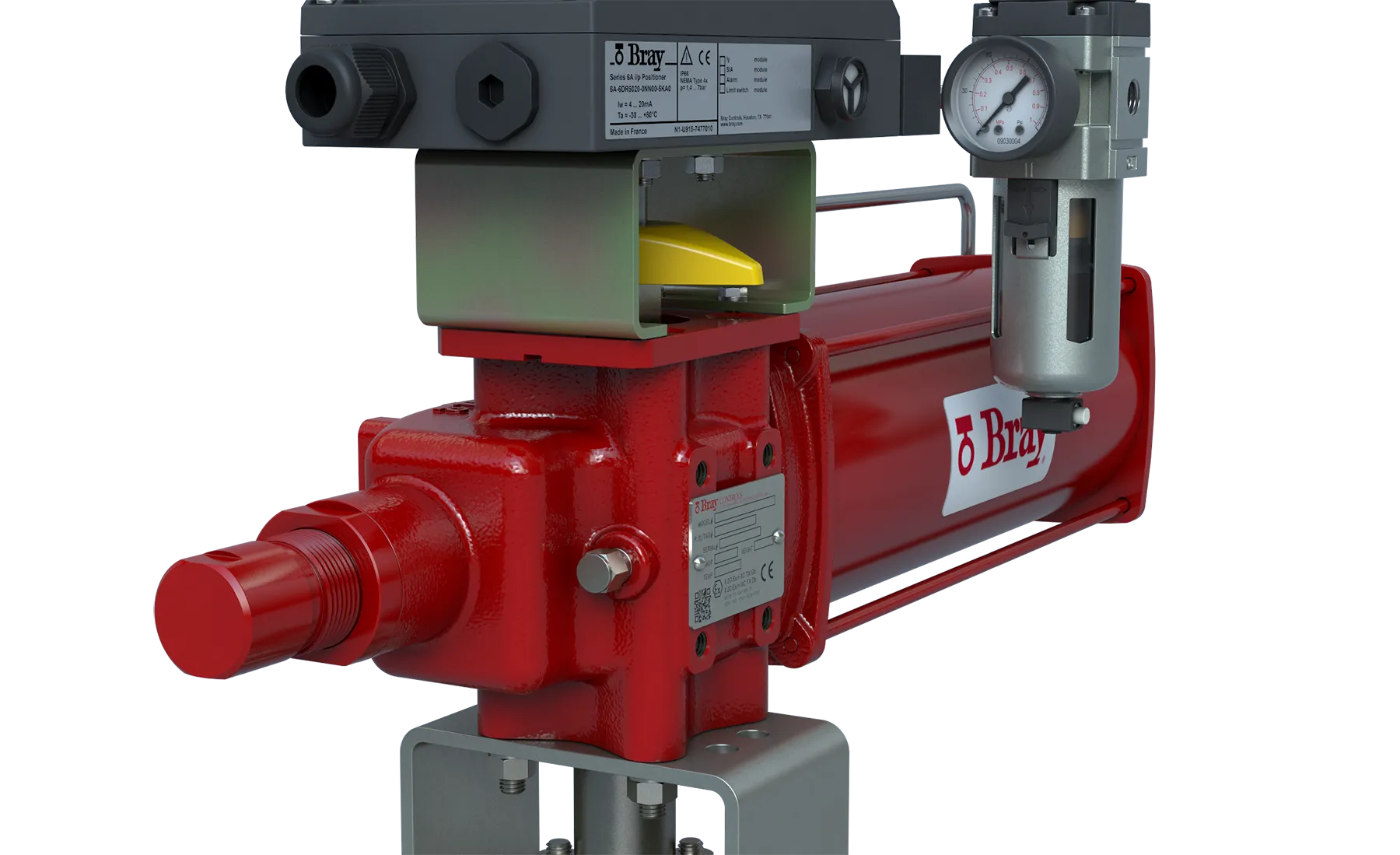

Standard 98C valve adaption includes two easily adaptable ISO 5211 mounting surfaces with a square drive output shaft which are designed to adapt to any quarter turn valve. Conversion from fail clockwise to fail counterclockwise direction is as easy as simply flipping the actuator over and reattaching to the valve. A VDI/VDE 3845 accessory mounting pad readily accepts switchboxes, sensors or positioners for provide position feedback to a facilities host system.

The 98C isn’t just a piece of equipment; it’s a long-term partner in performance. Maximize uptime, reduce repair cycles, and achieve optimal functionality without compromise. easy maintenance: just replace the soft components, and it’s ready to deliver peak performance year after year.

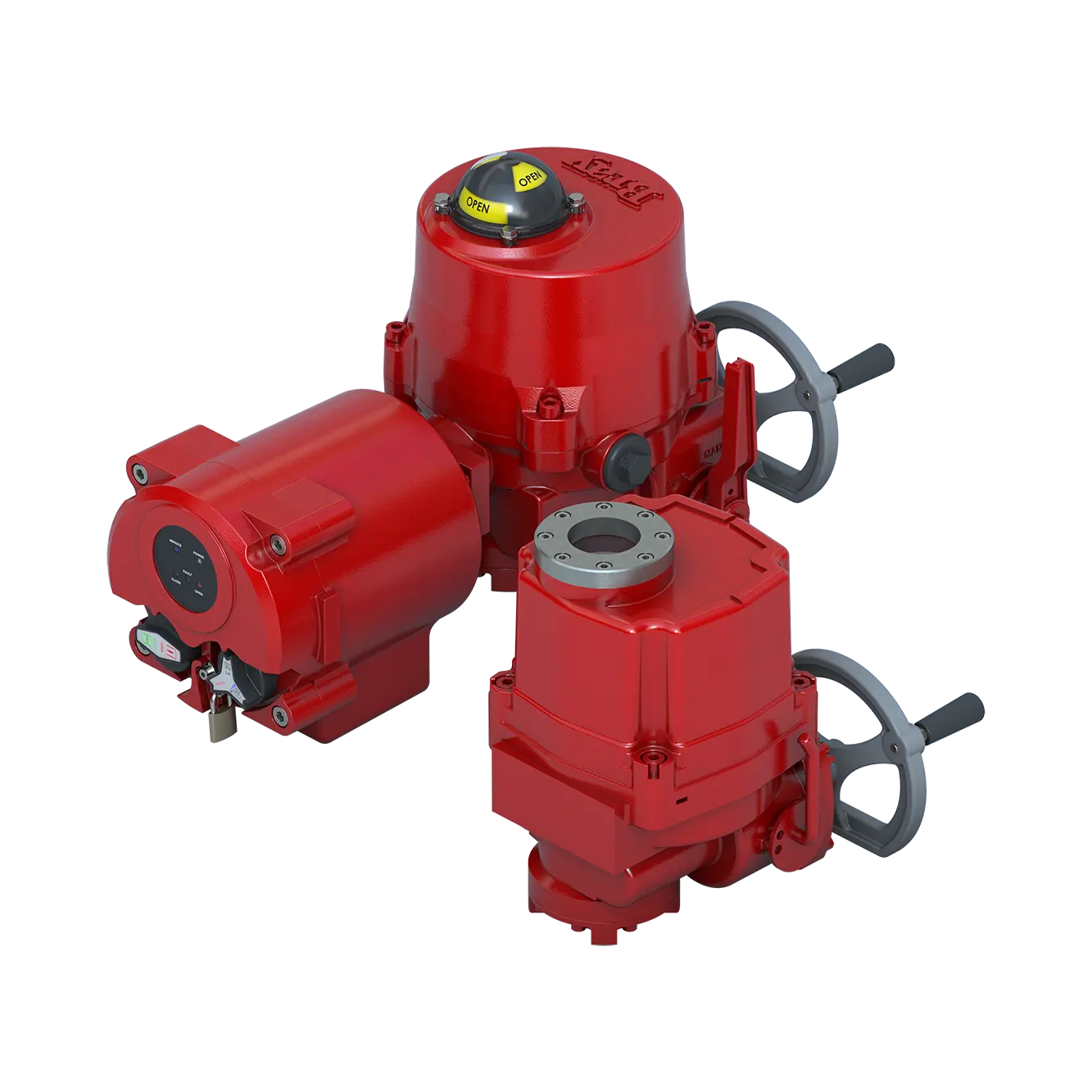

Have multiple power sources in your facility? Don’t worry, a Series 98C may be controlled with a pneumatic or hydraulic power source. Optionally, if electric power is the only energy source, the 98C can utilize Bray’s electro-hydraulic power unit for self-contained and emission free operation.