More Details

Features & Benefits

-

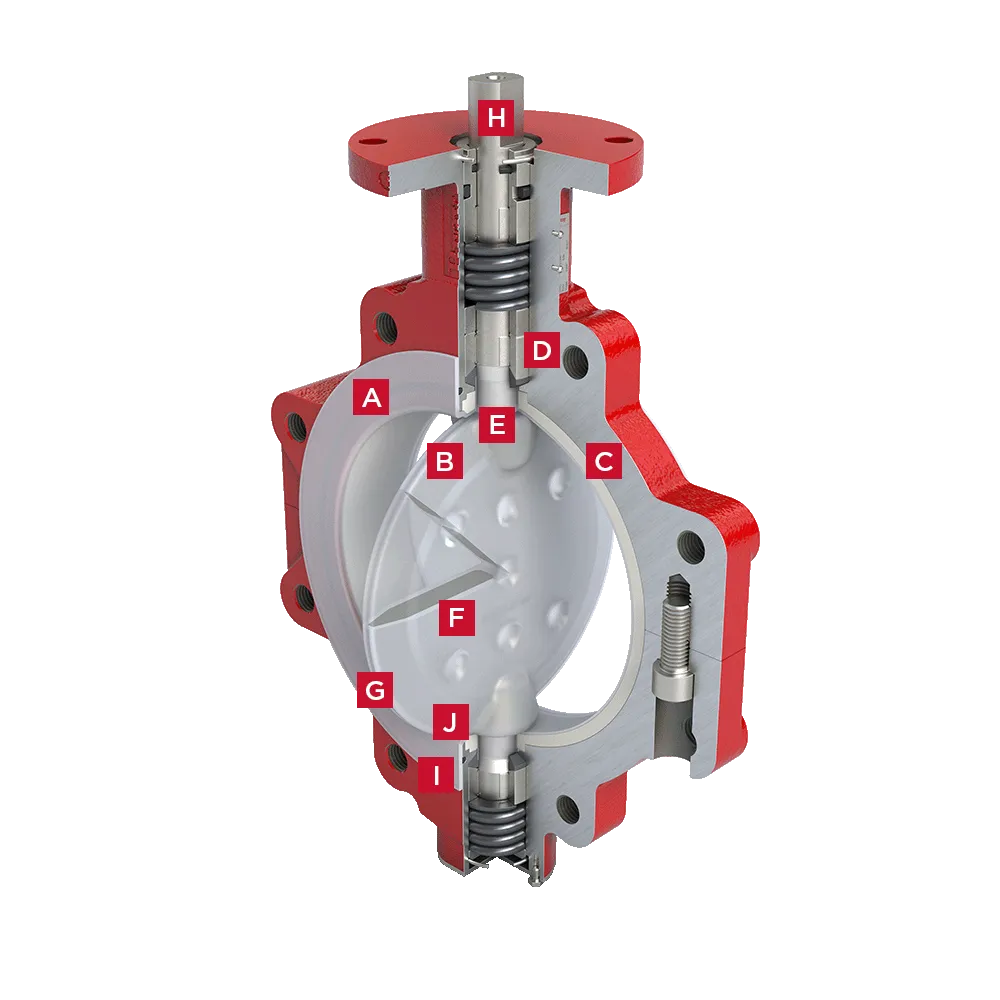

A. Fully PFA lined disc and body

Proprietary compound provides unsurpassed resistance to corrosion, permeation, and microbial contamination for maximum purity and reliability with minimum maintenance.

-

B. Durable, spherically molded PFA liner and matching disc

Interface forms a tight bidirectional seal.

-

C. Full width 360° seat energizer

Ensures uniform sealing.

-

D. Live-loaded, stem sealing system

Self-adjusts to eliminate leak paths and reduce fugitive emissions for long-term, maintenance-free operation. (Standard sealing system meets ISO 15848-1 low fugitive emission requirements.)

-

E. Extended PFA shaft over-molding

Enhances stem sealing, eliminates leak paths, and shields the stem from corrosive media.

-

F. PFA disc over-molding

PFA resin is mechanically bonded to the base metal to enable vacuum capability.

-

G. Streamlined disc

Engineered for maximum flow.

-

H. High-strength, one-piece 17-4 stainless steel disc and stem

Standard for improved reliability.

-

I. Energized flange seal

Maintains proper sealing between valve and flange.

-

J. Mechanically retained seat energizer

Wide elastomer seat energizer rests in a machined body groove to enable end-of-line service at full working pressure.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business