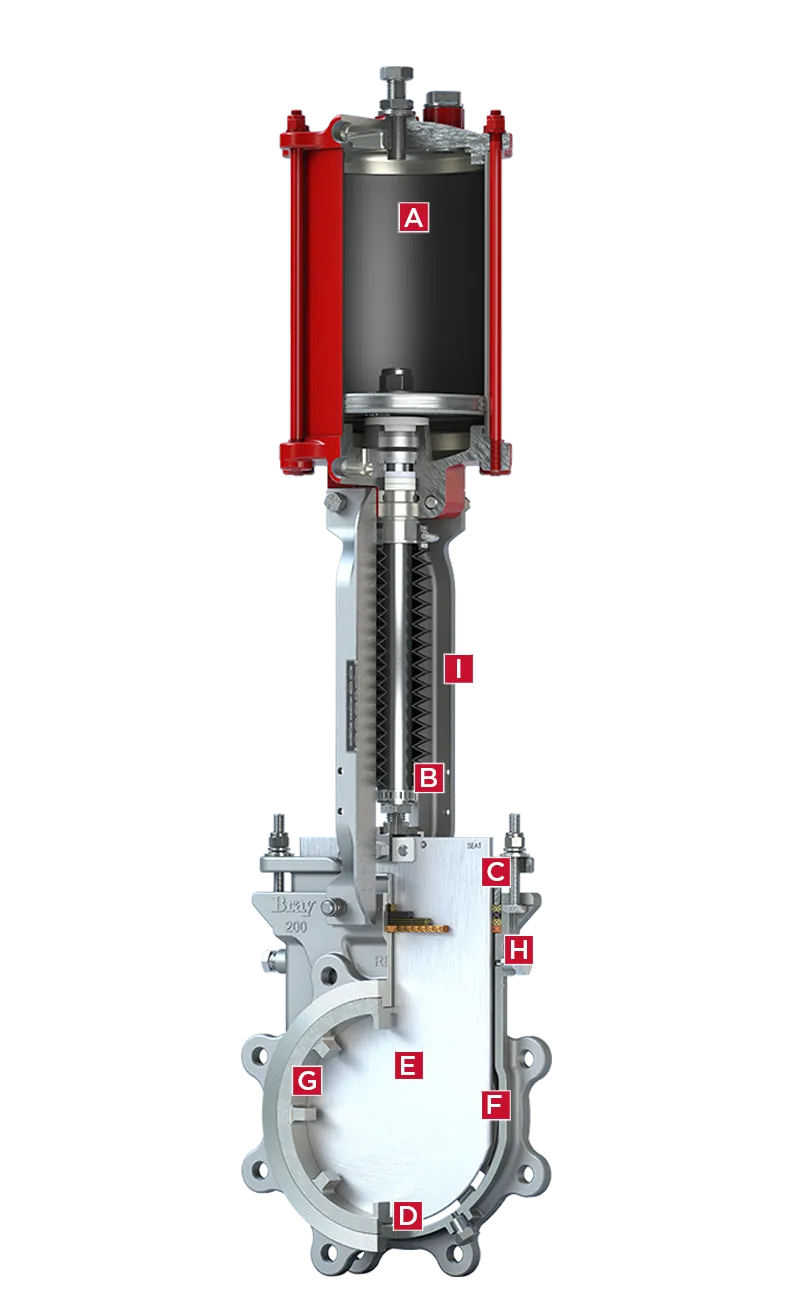

Bray's Series 942 Vortex Breaker Knife Gate Valve is designed to meet the demands of on/off isolation service within pulp and paper recycle and reject applications. It excels in high-cycle services, where robust shearing capabilities are paramount, particularly in environments with cyclone separators and recycle high-density cleaners.

The Bray Series 942 Vortex Breaker Knife Gate Valve presents an engineered solution featuring a standard replaceable Vortex Breaker. This feature serves to disrupt cyclonic flow formation, preventing premature gate and body damage and ensuring prolonged operational efficiency and reliability. The Hi-Chrome vortex breaker (500 HB) designed to disrupt cyclonic flow formation of reject materials (staples, wire, nails, sand, etc.) provides extended service life. The adaptability of the Bray Series 942 Vortex Breaker Knife Gate Valve spans multiple industry applications, from Knotter to Rejects, Pulpers, HD Cleaners, Cyclone Separators, and Junk Traps.

-copy_d.webp)