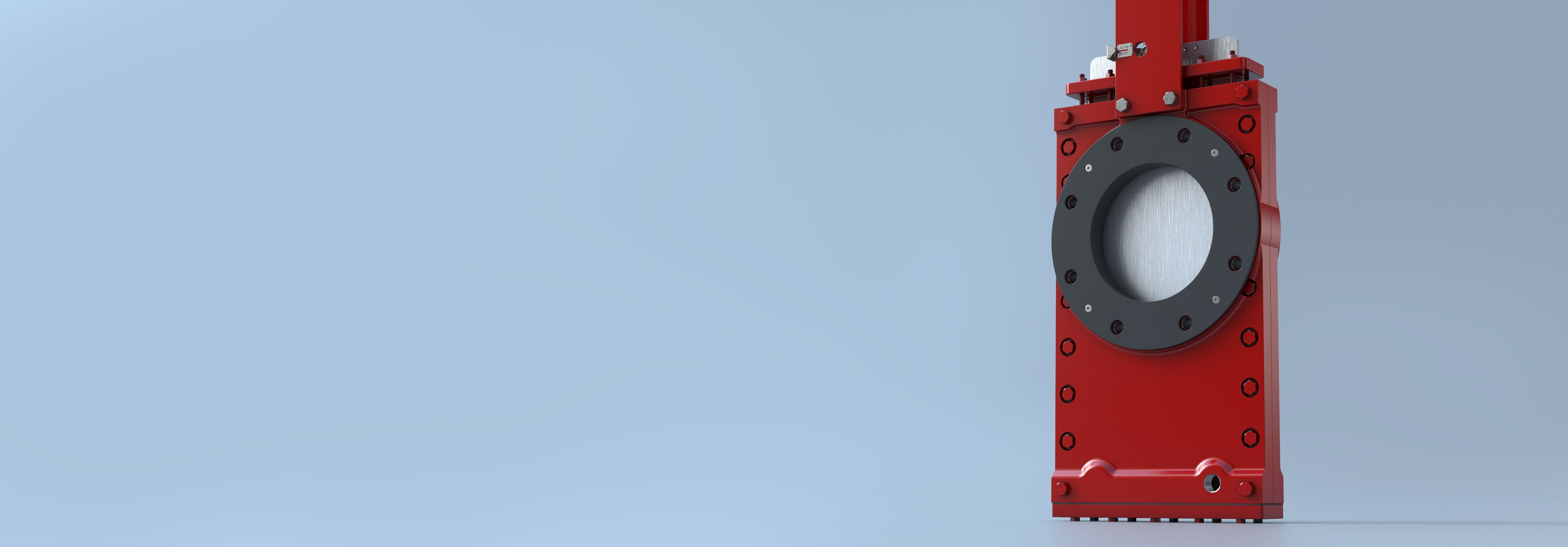

The Bray Series 770 bidirectional o-ported knife gate valve is designed for severe service applications. The 770’s o-ported gate is in constant contact with the seats, minimizing seat stress and ensuring maximum sealing performance.

The durable ductile iron body is offered in a compact wafer style. When fully open, the valve is full bore, offering no resistance to line media.

Specifications

-

Features & Benefits

-

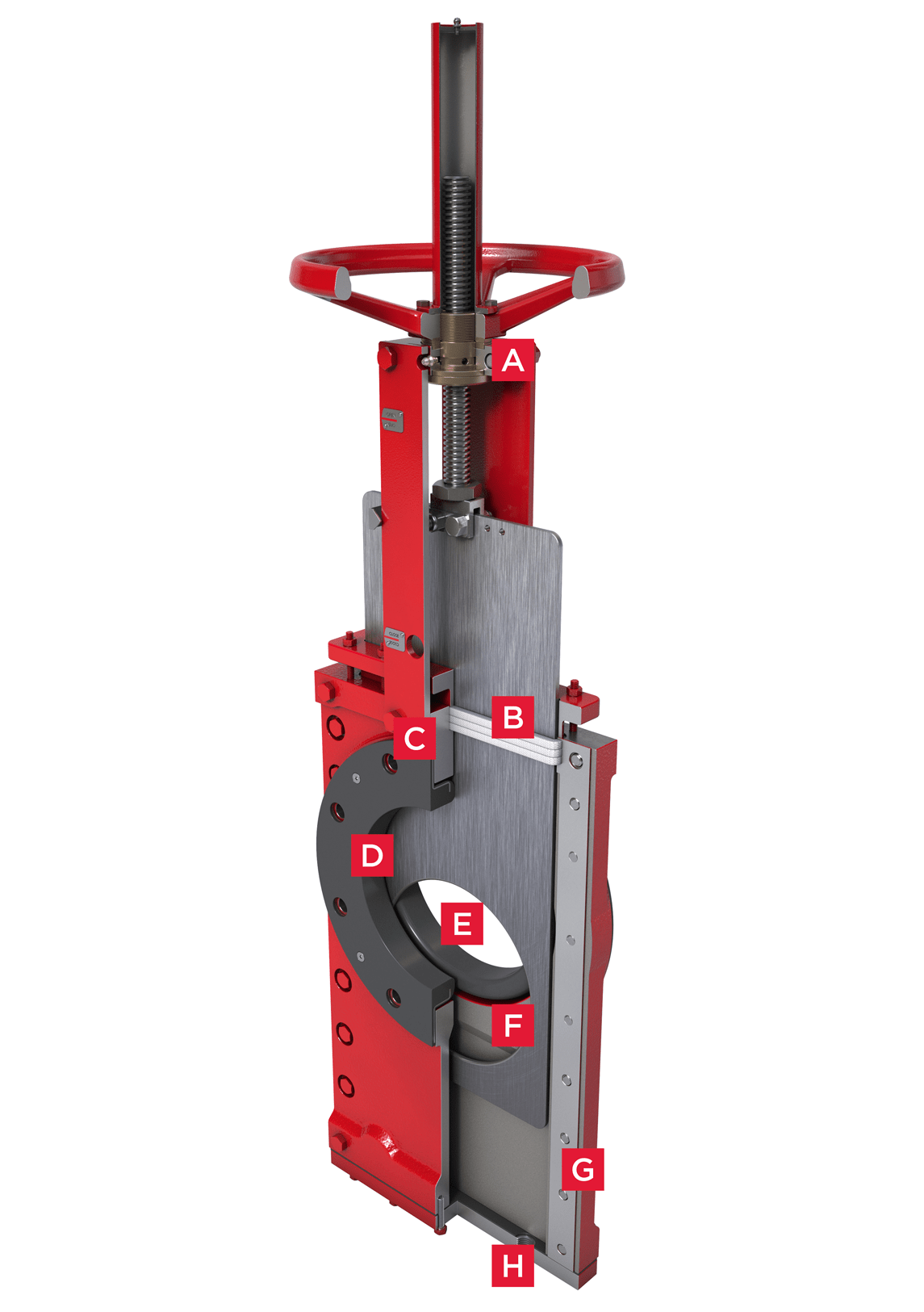

A. Topworks

Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance.*

-

B. Packing

Multi-layer square packing provides exceptional gland sealing.

-

C. Seat

Replaceable steel reinforced, elastomer seat ensures bi-directional zero leakage shutoff.

-

D. Seat Contact

Seats are in constant contact with gate throughout the entire stroke of the valve.

-

E. Gate

Deflection resistant gate design ensures consistent alignment for industry leading durability.

-

F. O-Port

The inherent design of the o-ported slide gate provides 360˚ scale-breaking.

-

G. Body

Compact wafer body allows for easy installation and is drilled and tapped to ASME CL150 flange patterns as standard. Other drilling options available upon request.

-

H. Tapped Flush Port

Non-discharging body design includes tapped flush ports as standard, allowing for safe discharge of media and easy flush water connection.