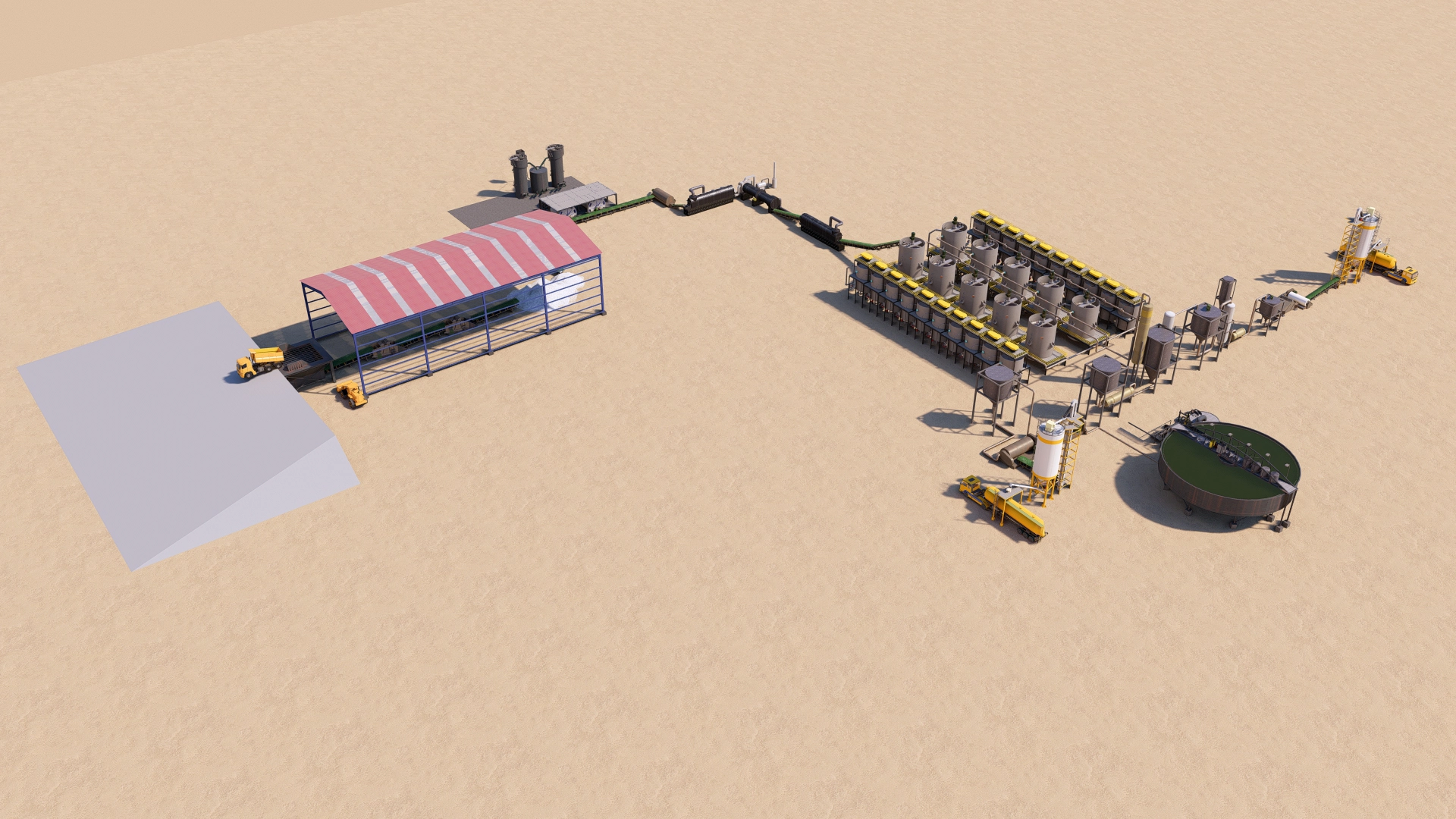

Solutions pour le secteur de l'extraction du lithium

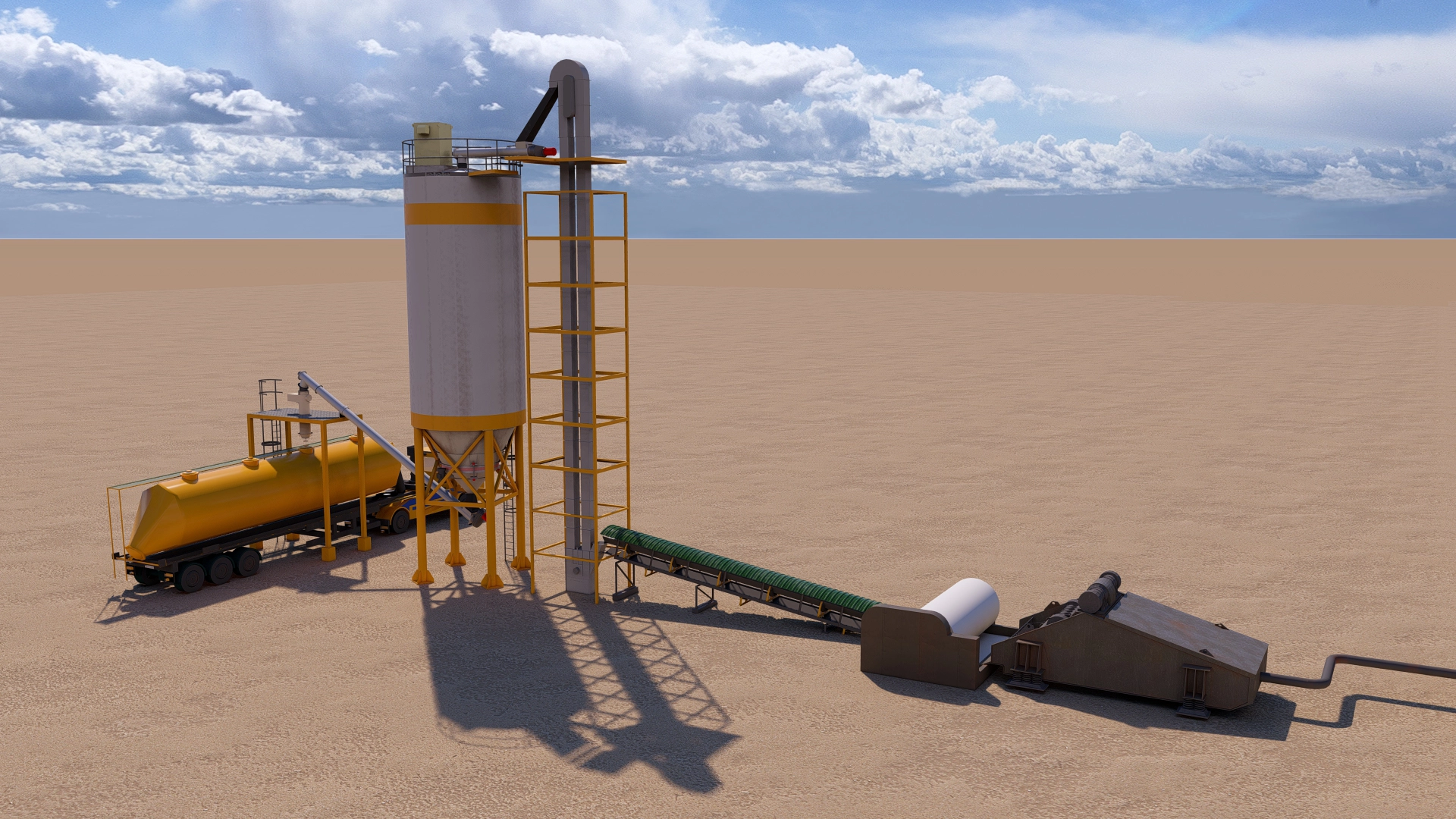

Circuit de broyage

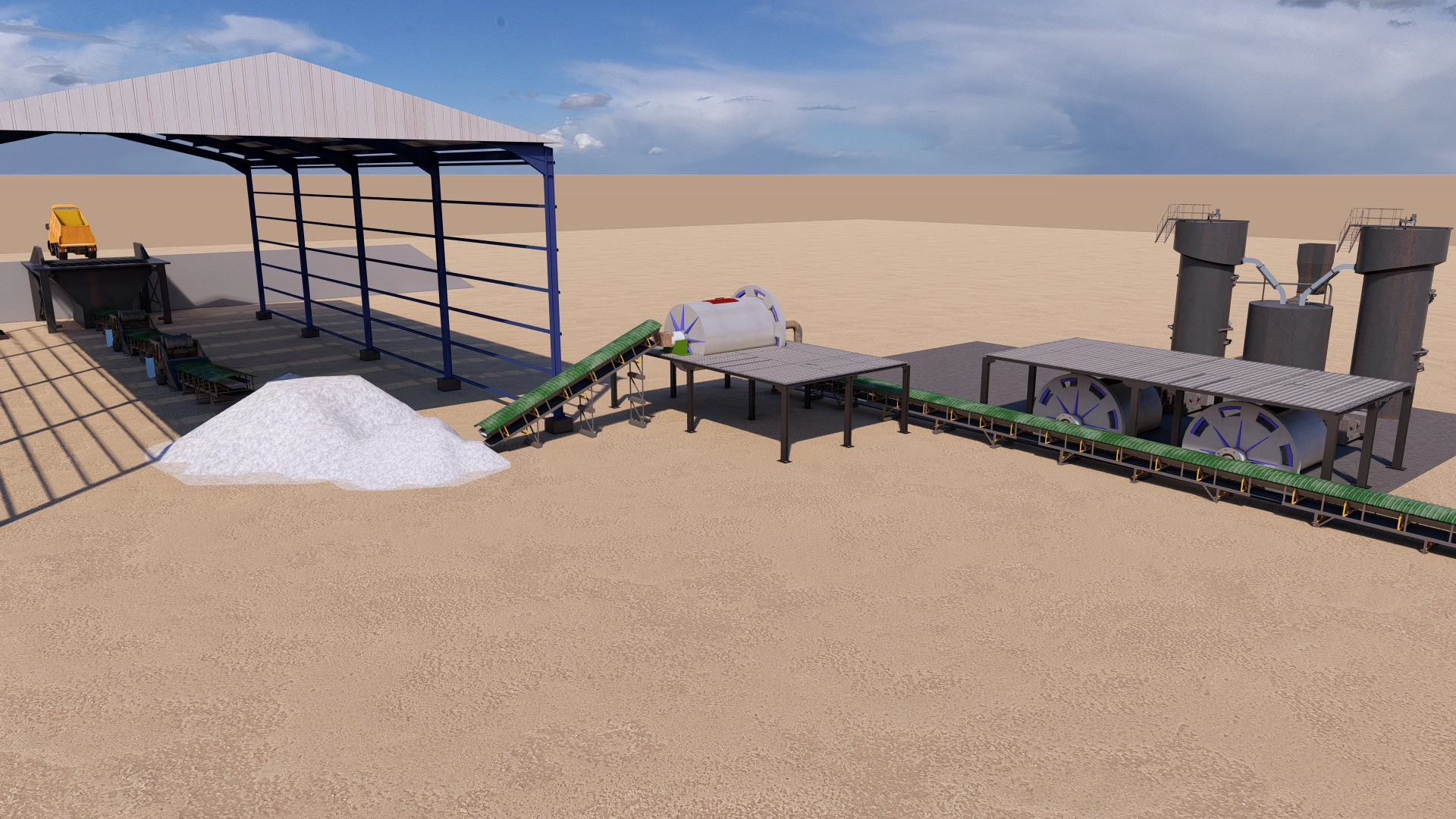

Lits et calcinateur fluidisés

Lixiviation/Flottaison

Évaporation et cristallisation

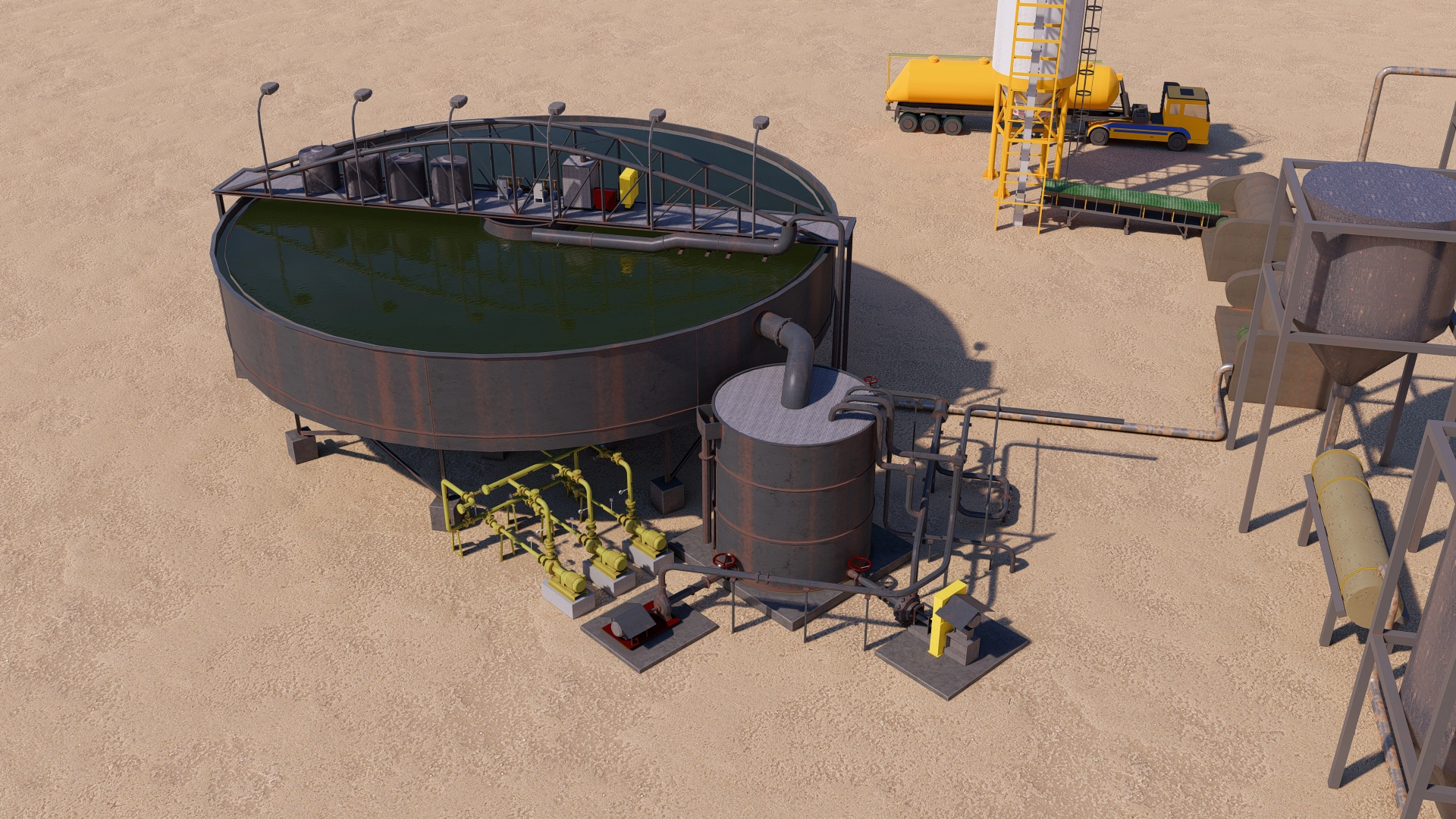

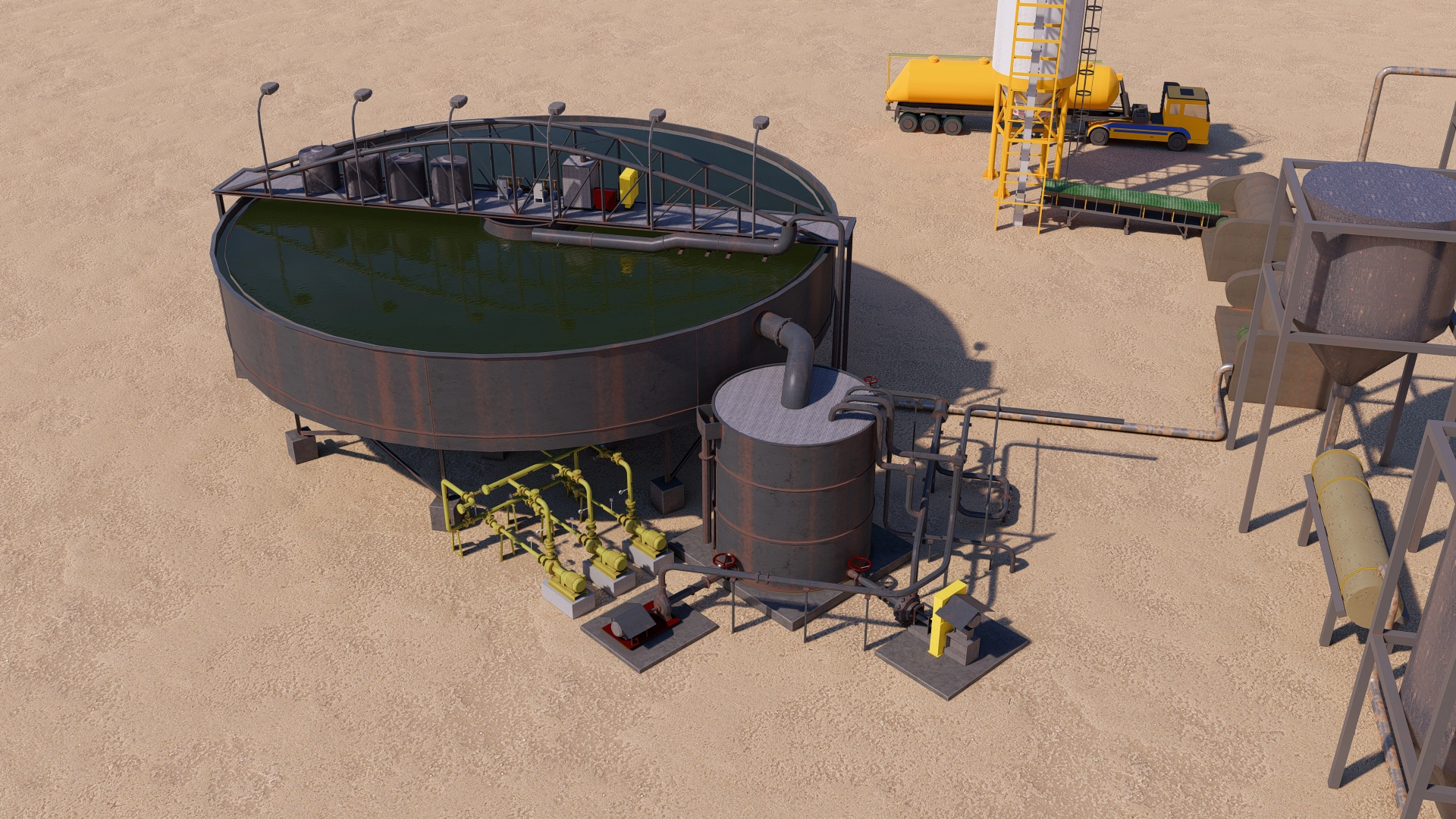

Épaississement

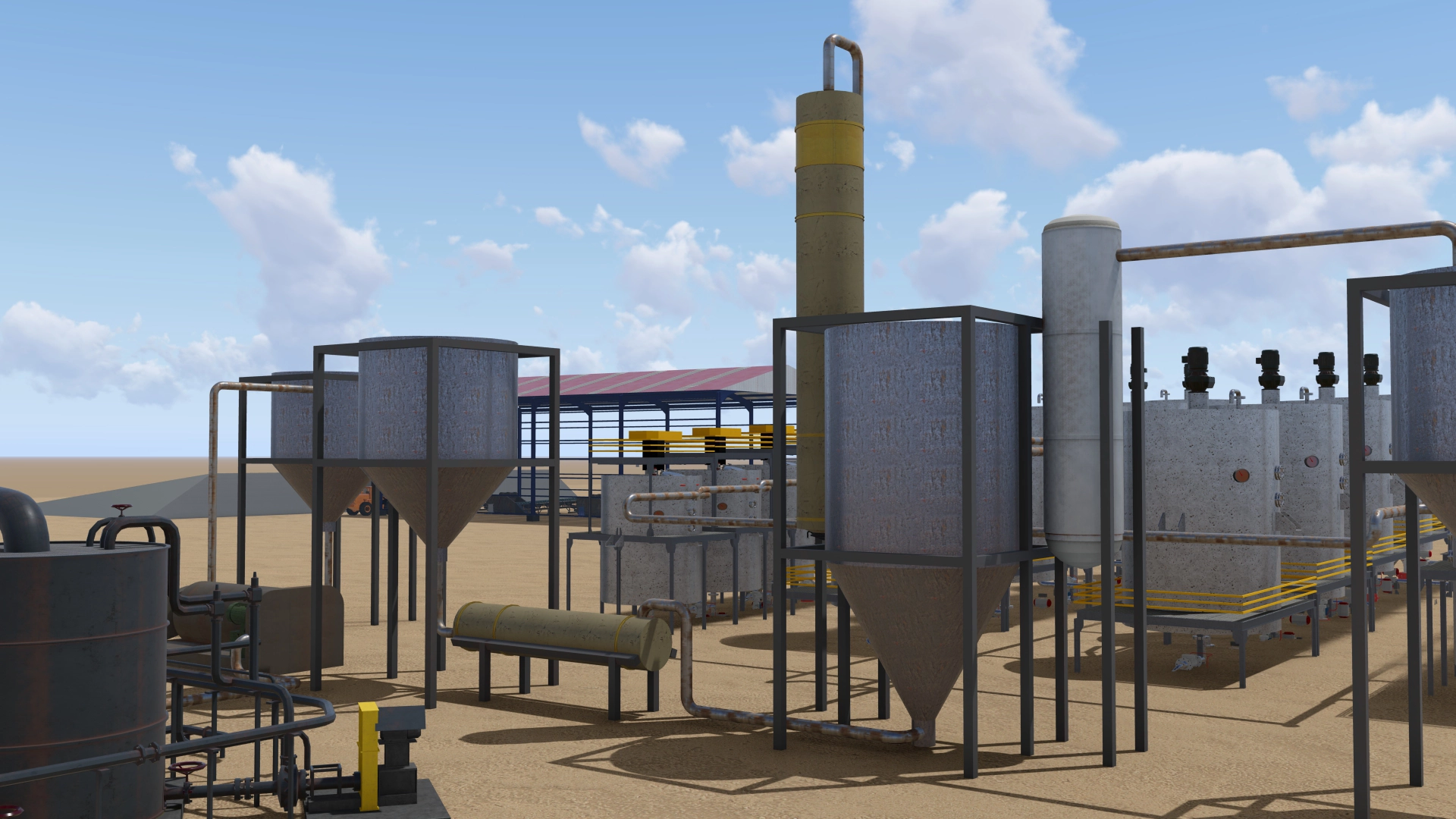

Réservoirs de récupération de lithium

Filtrage et séchage

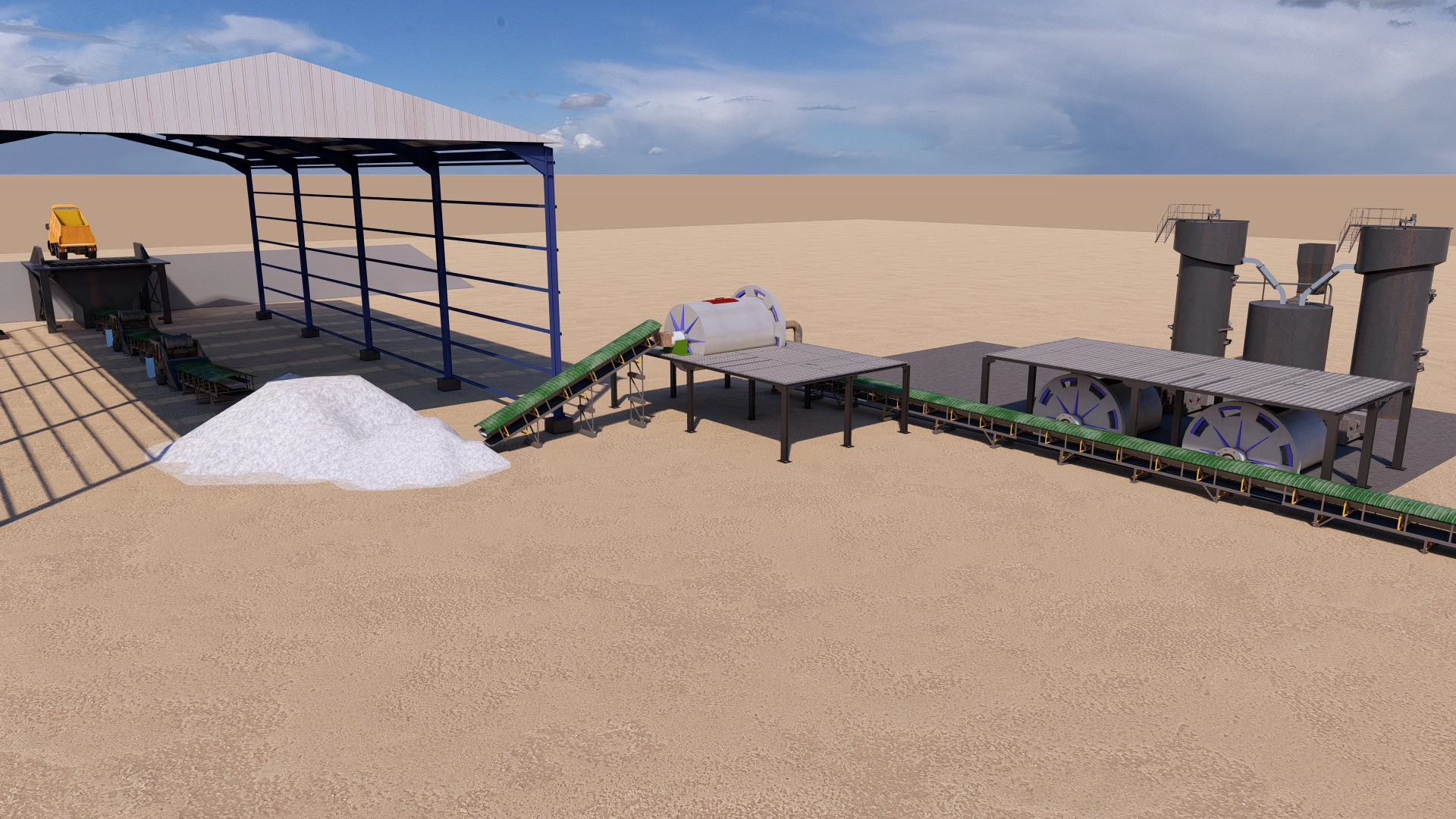

Circuit de broyage

Le minerai spodumène est broyé et concassé en petite taille pour la préparation. Les réactifs hydrite et dualamite sont broyés et ajoutés au processus.

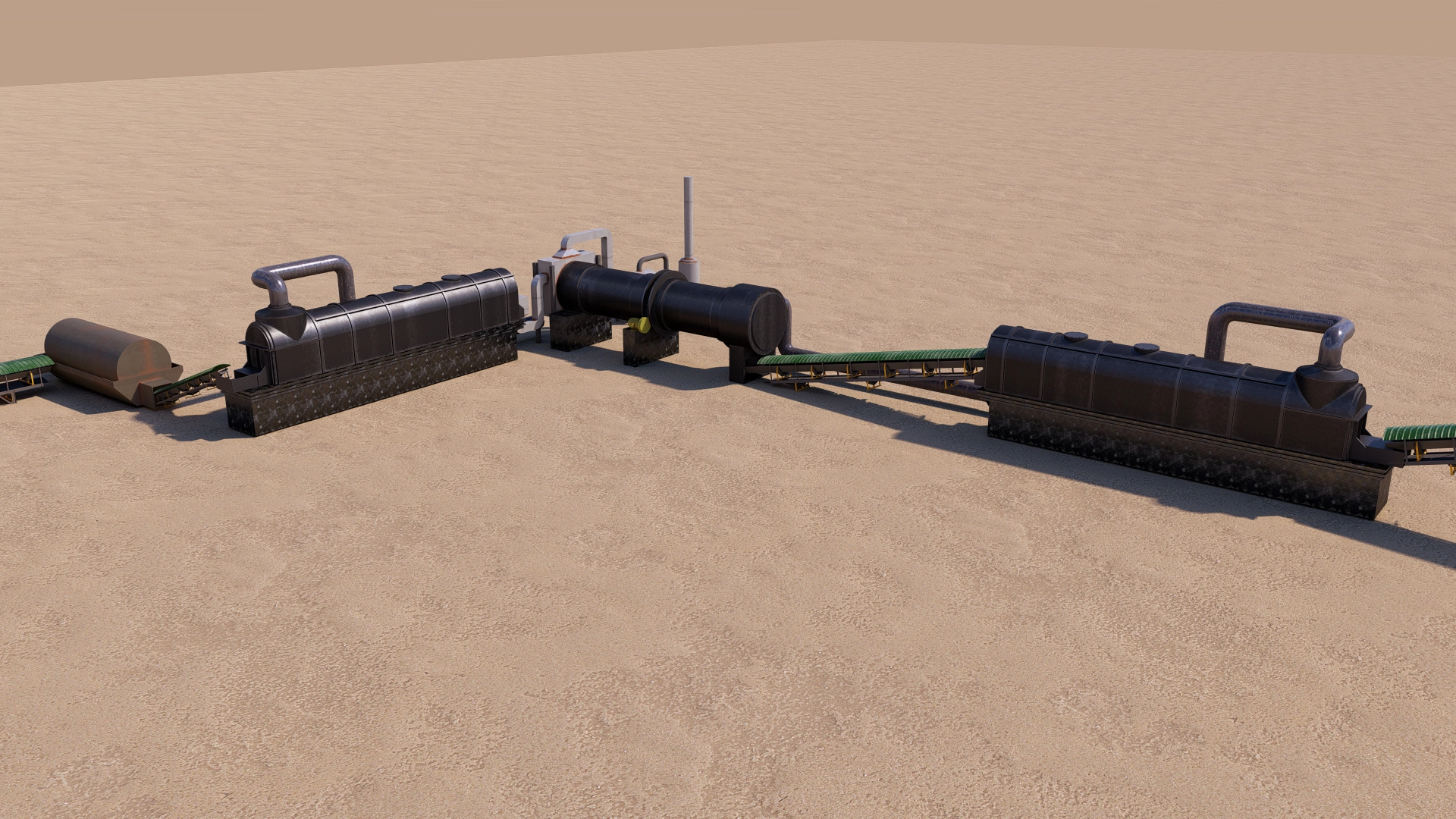

Lits et calcinateur fluidisés

Le lithium, le sodium et le potassium sont convertis en solvates solubles dans l'eau à 1000 °C, puis refroidis à l'air dans le calcinateur.

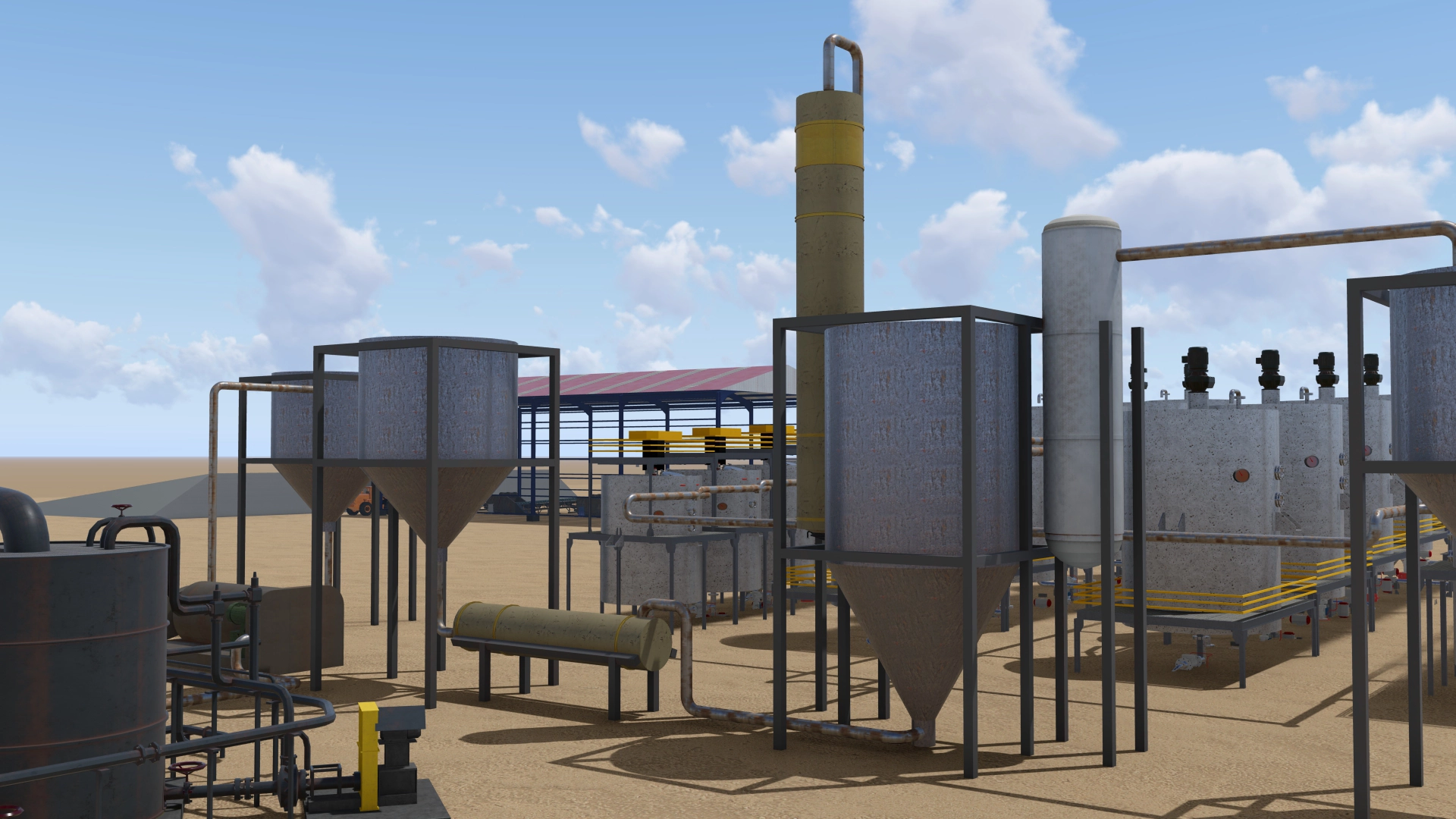

Lixiviation/Flottaison

Dissous, avec des traces de magnésium et de calcium. D'autres impuretés restent insolubles. La solution de lixiviation est soumise à un cycle pour maximiser la concentration de lithium.

Évaporation et cristallisation

Une solution de lixiviation clarifiée est mélangée avec des solutions recyclées et alimentée aux évaporateurs, le sulfate de lithium est ainsi plus concentré.

Épaississement

Concentre les boues en éliminant l'excès d'eau par gravité pour concentrer les solides fins, optimisant ainsi la densité des boues pour la filtration en aval afin d'obtenir du sulfate de potassium.

Réservoirs de récupération de lithium

Les traces de calcium et de magnésium sont éliminées du concentré, puis le carbonate de lithium est précipité en ajoutant du carbonate de sodium.

Filtrage et séchage

Filtre le sous-produit (sel de Glaubers) et le carbonate de lithium après la récupération du lithium, ou le sulfate de potassium après épaississement, lavage et séchage pour l'ensachage.

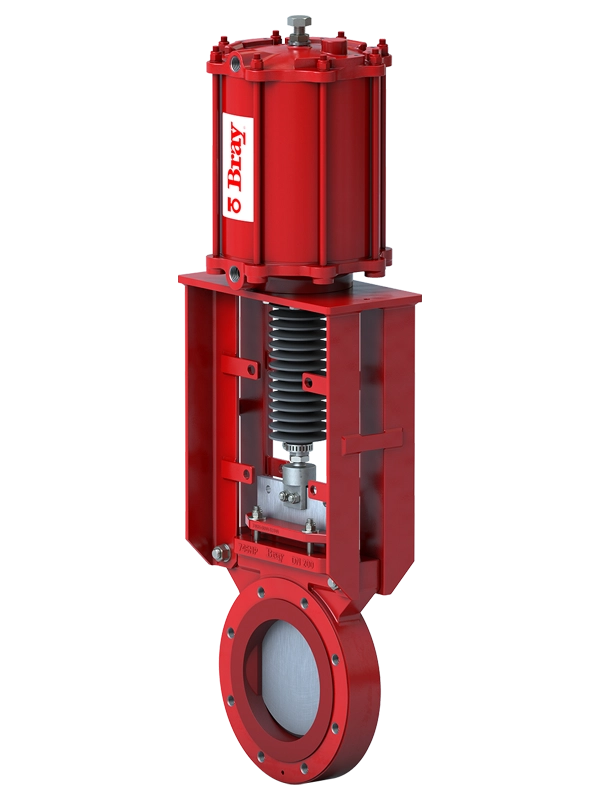

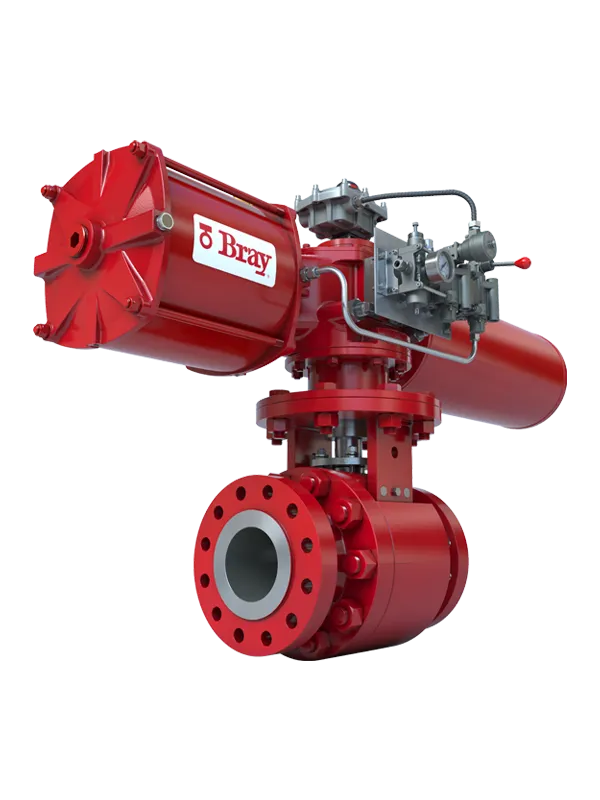

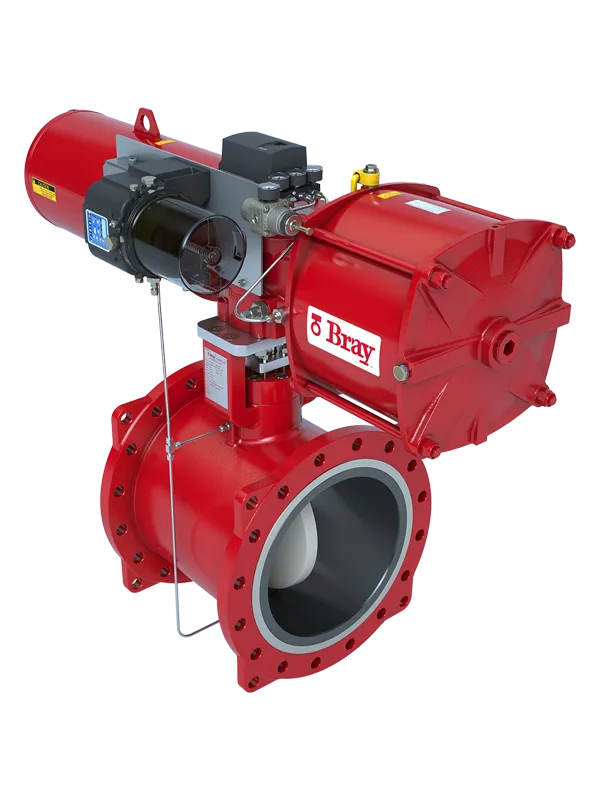

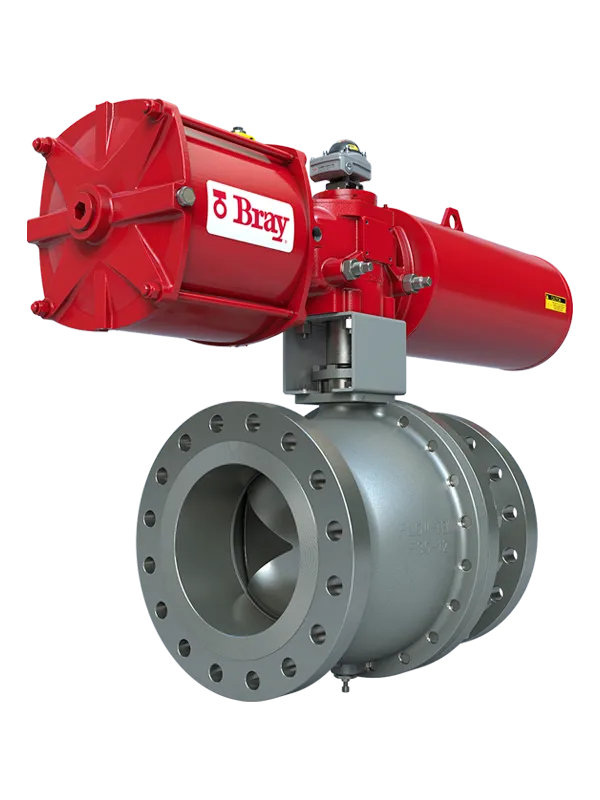

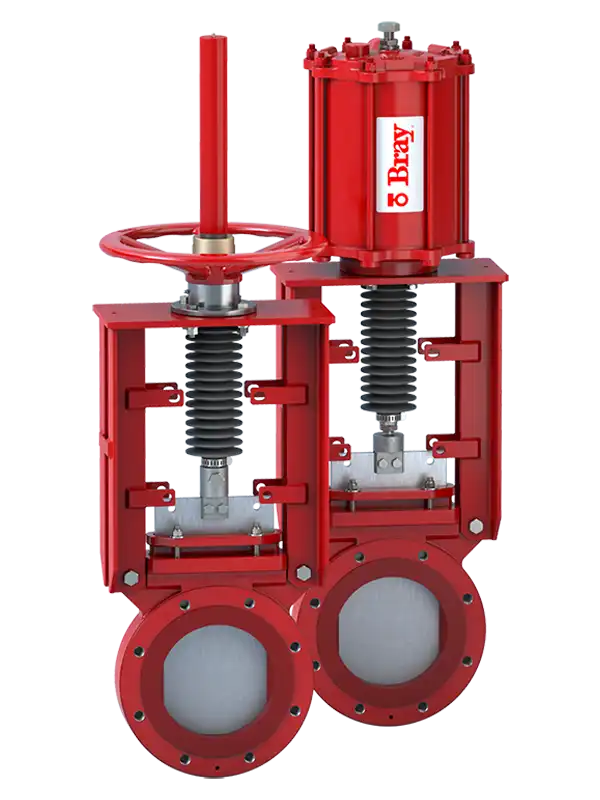

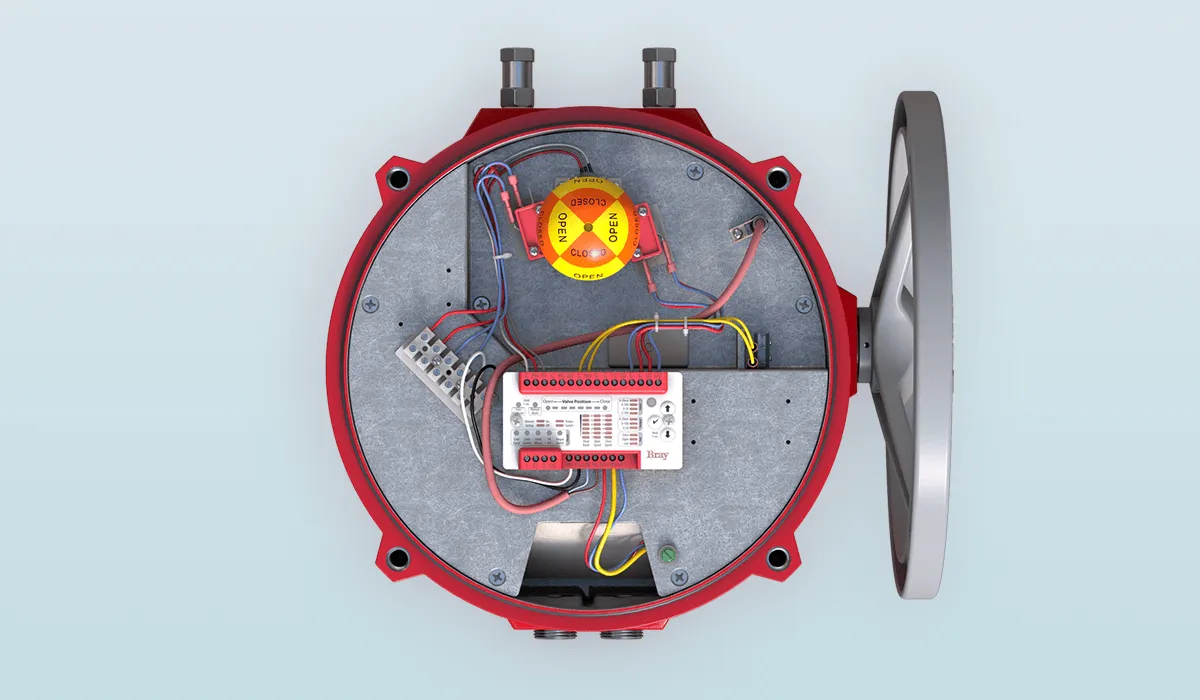

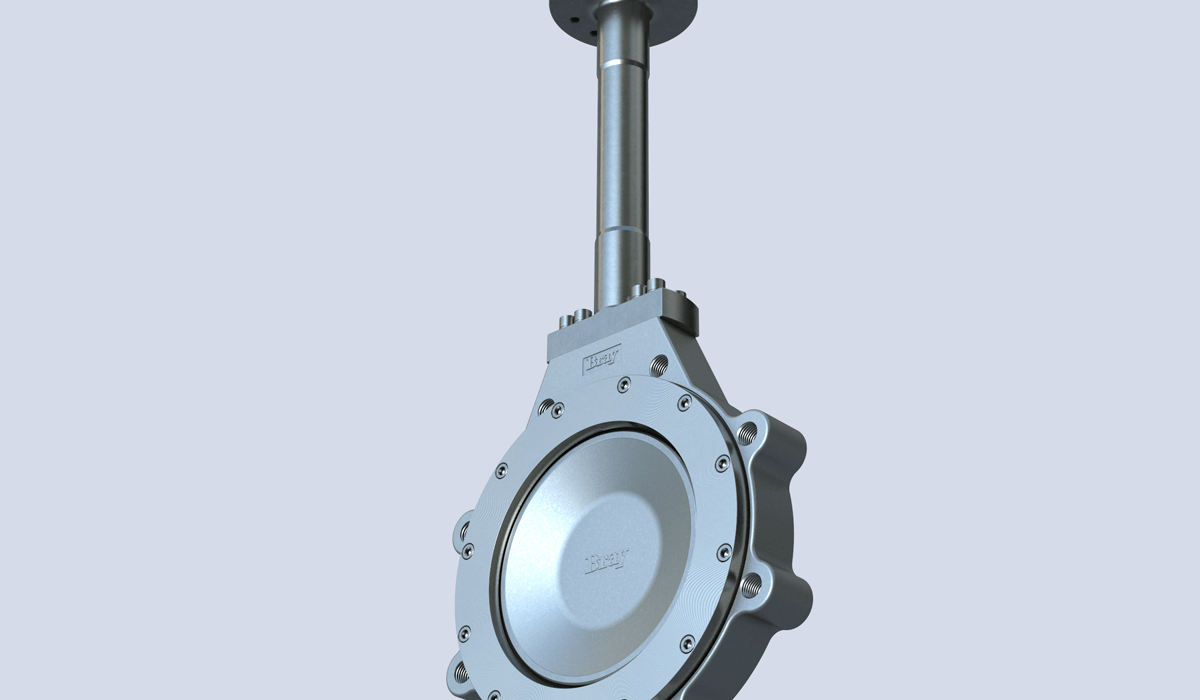

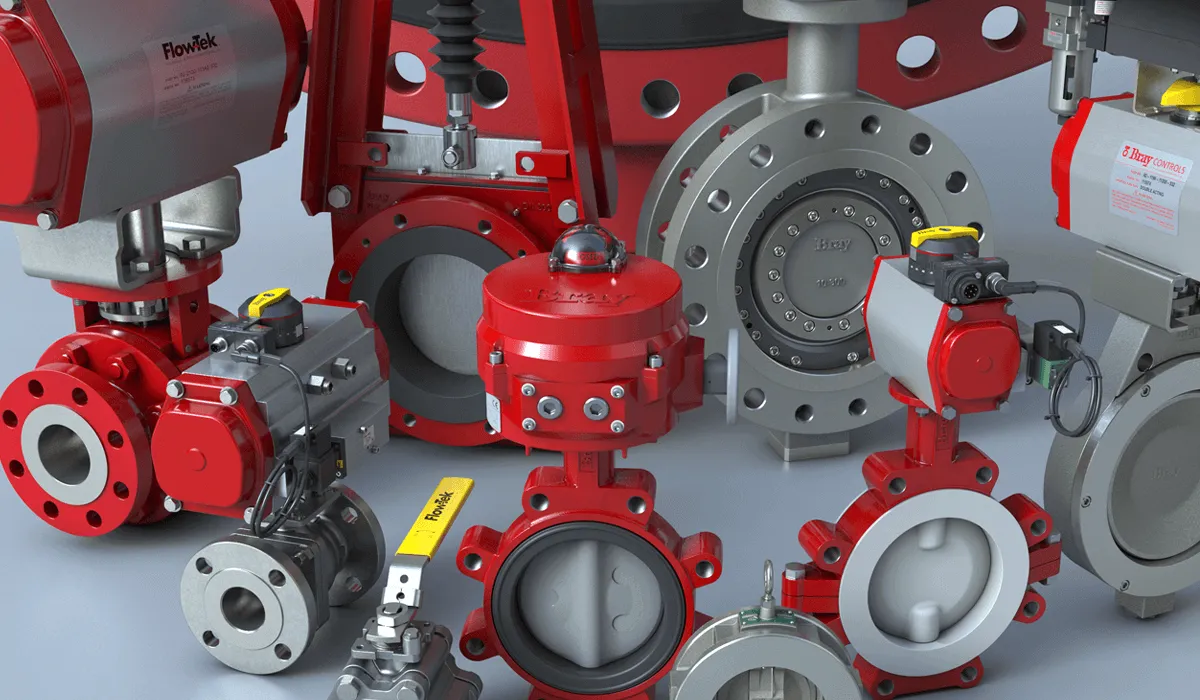

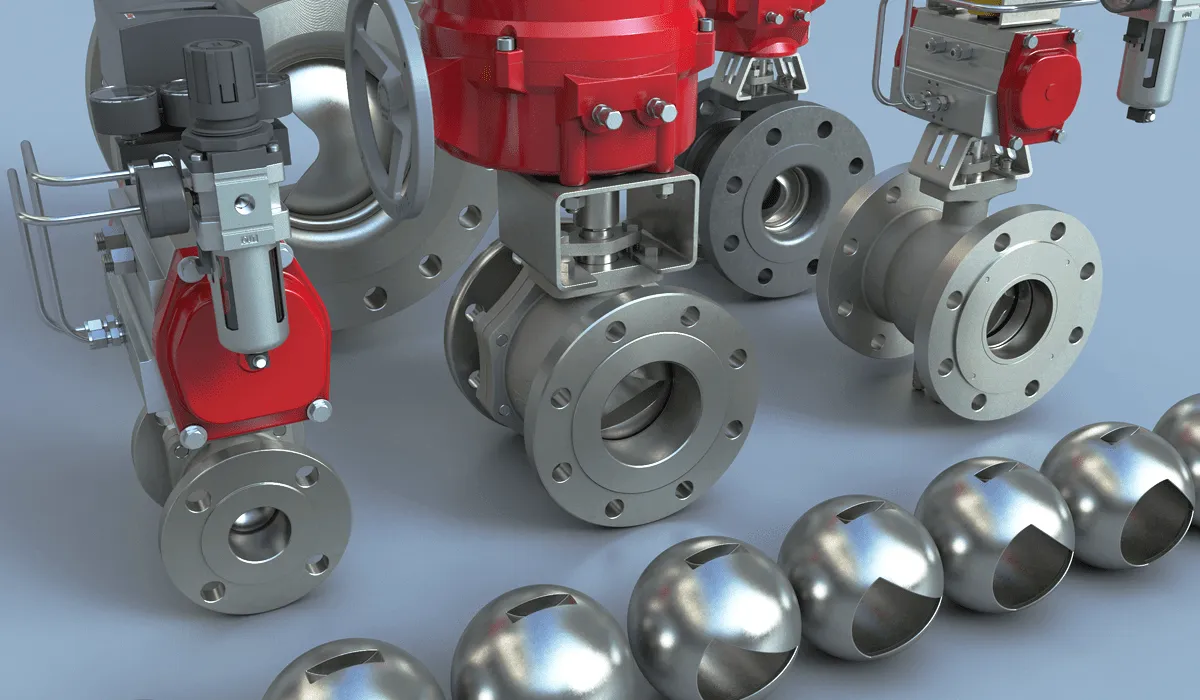

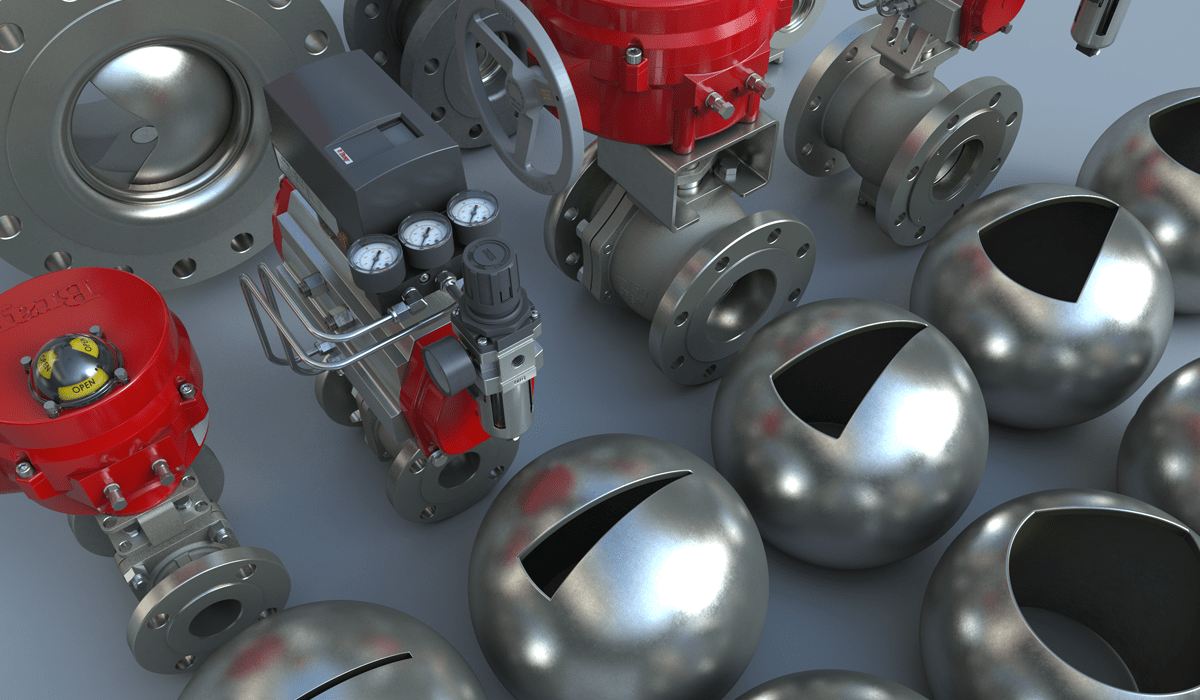

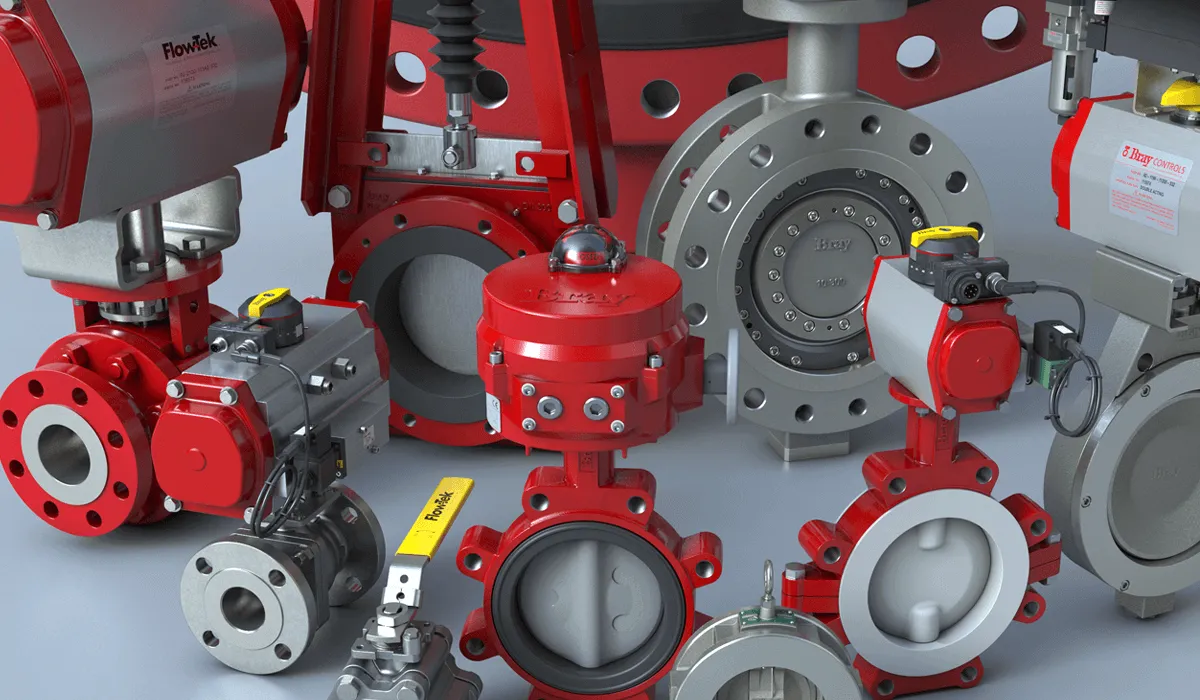

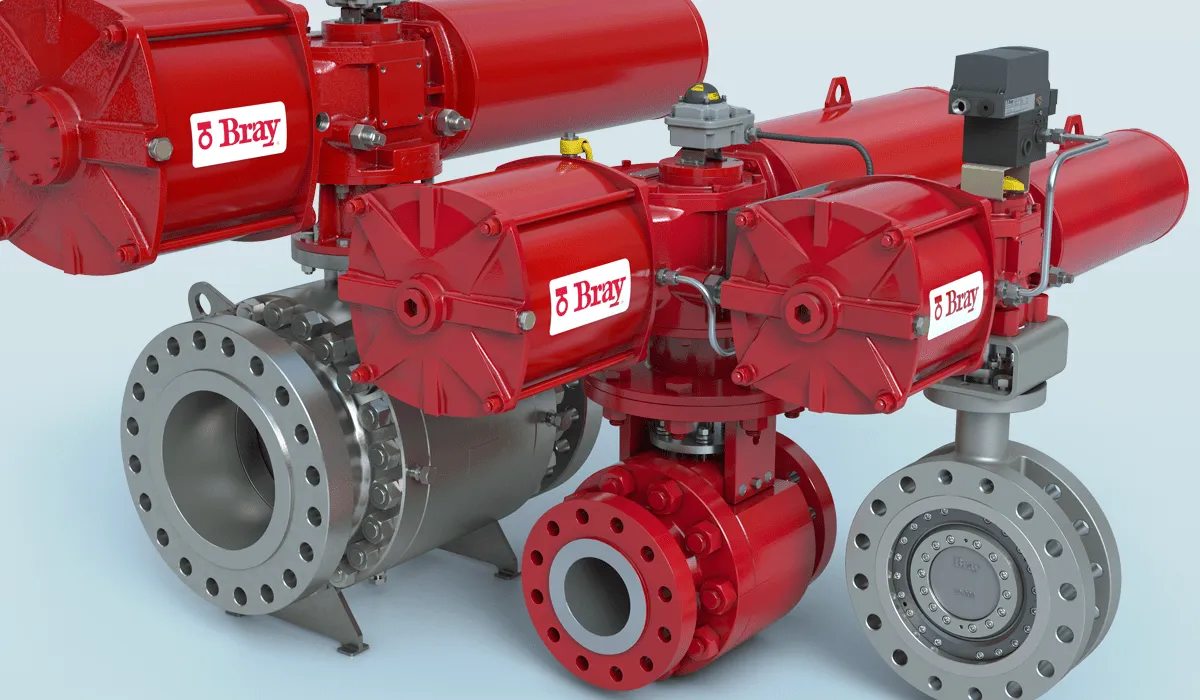

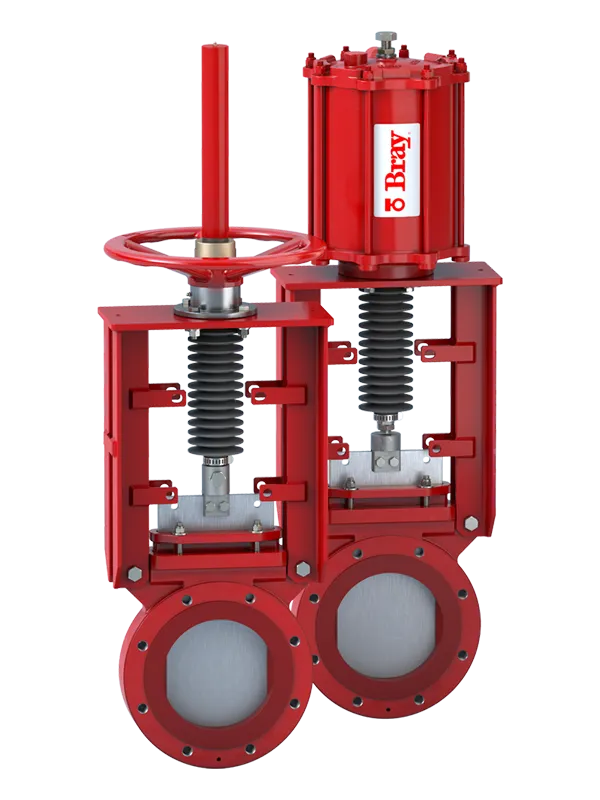

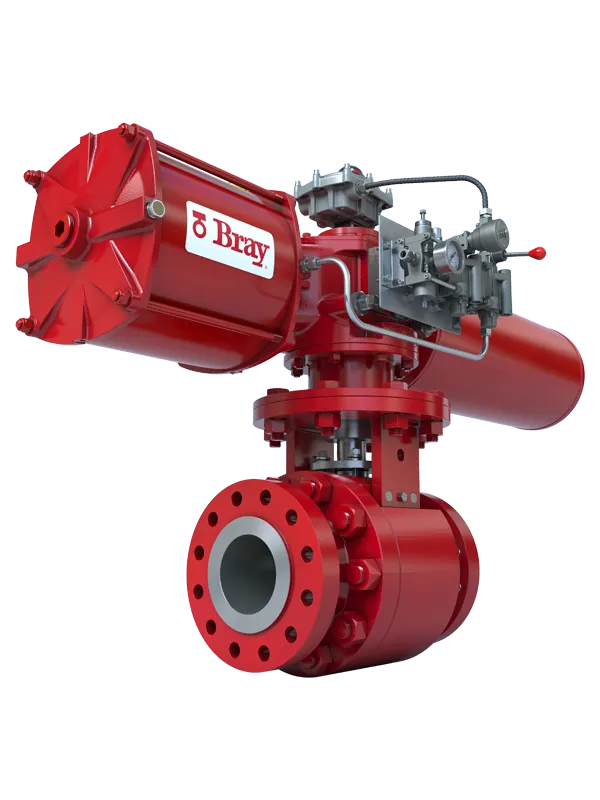

Améliorer la fiabilité des vannes - Sélection de robinets à tournant sphérique pour conditions difficiles

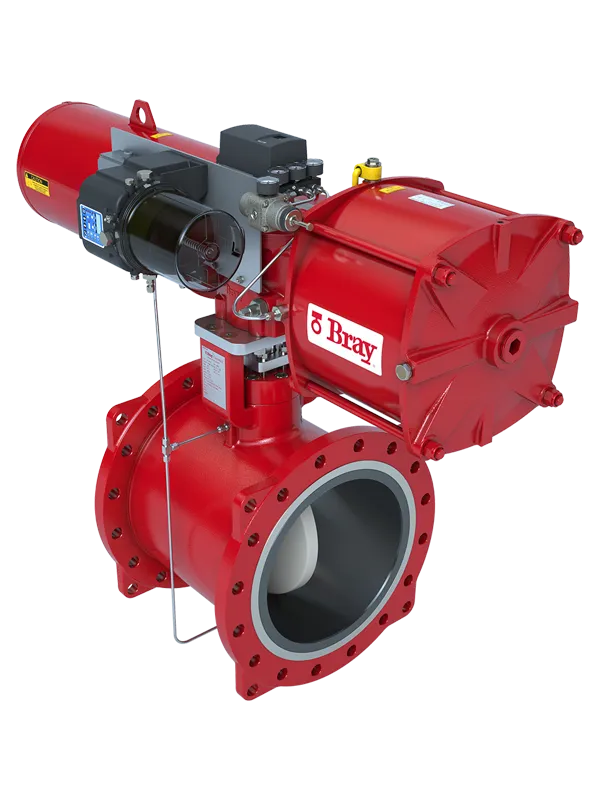

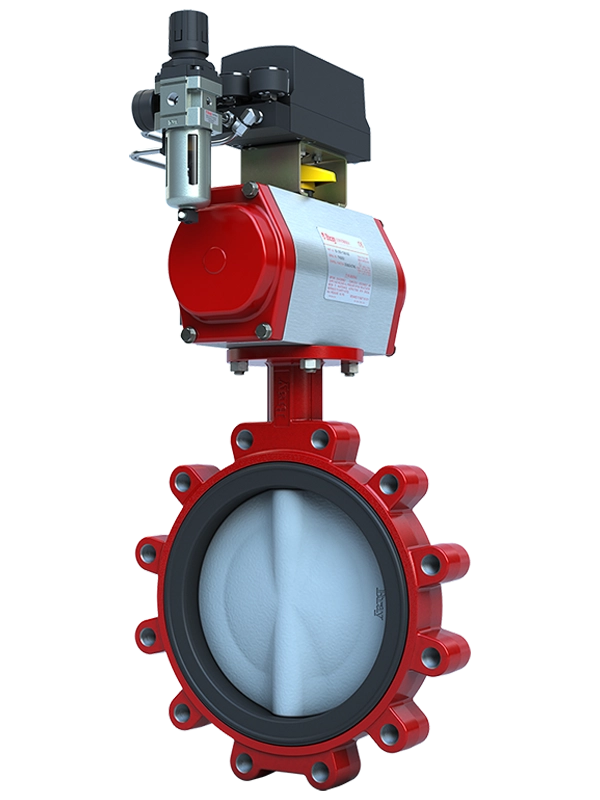

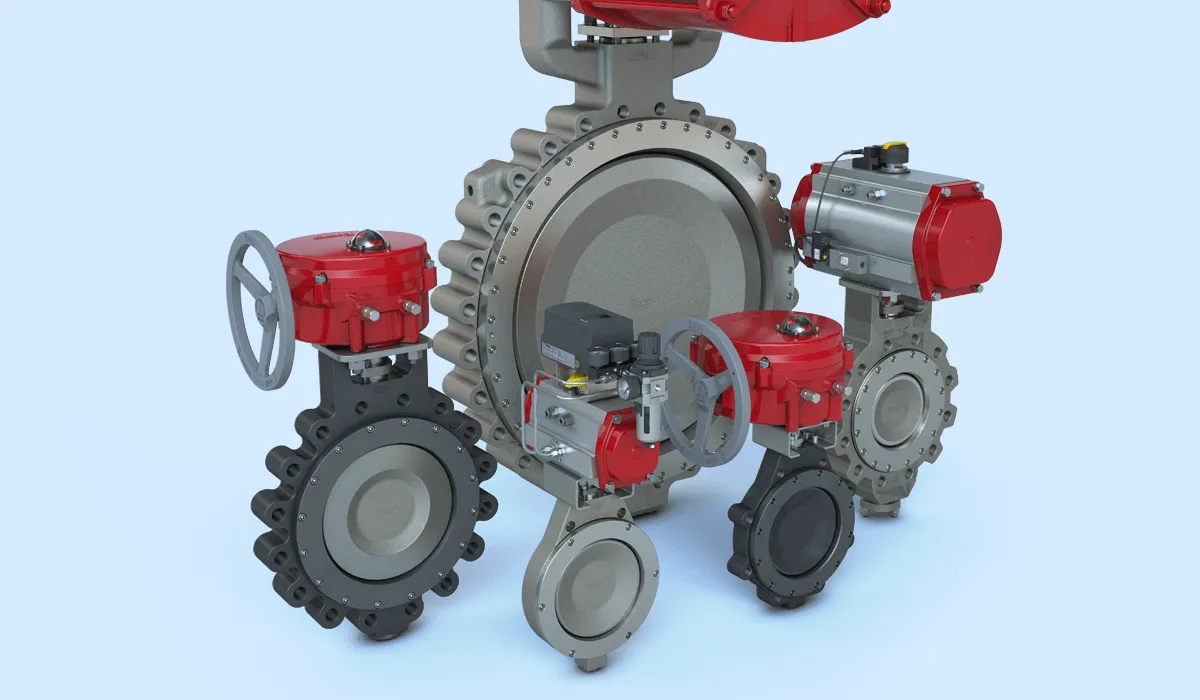

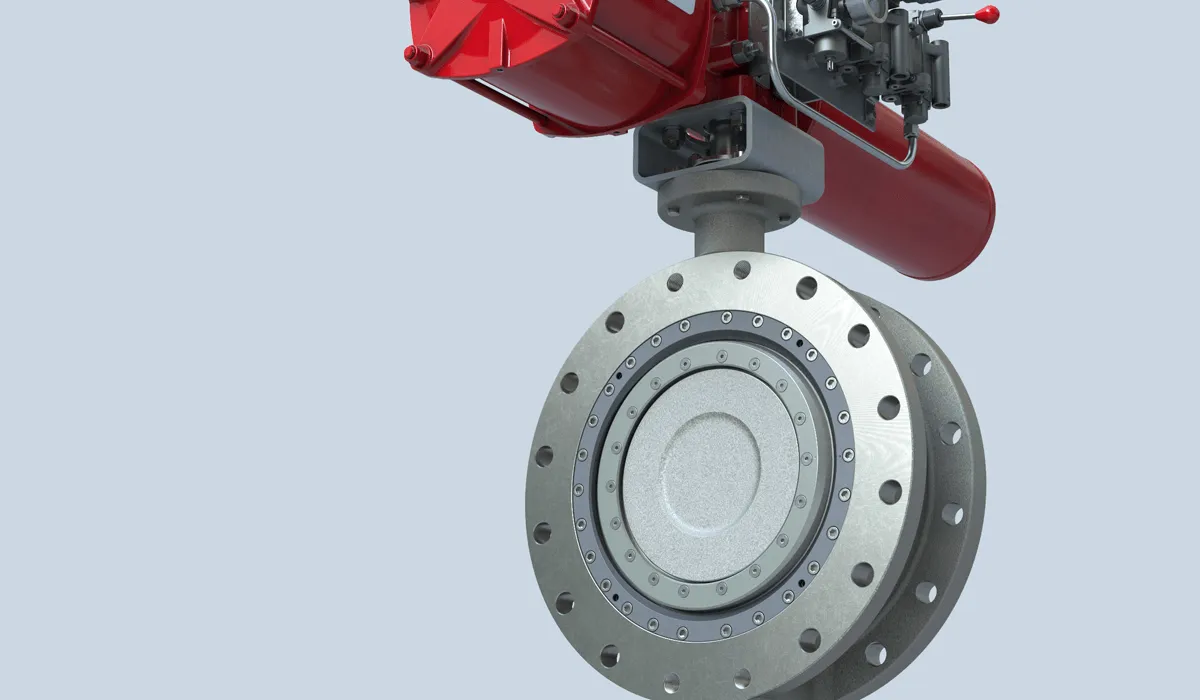

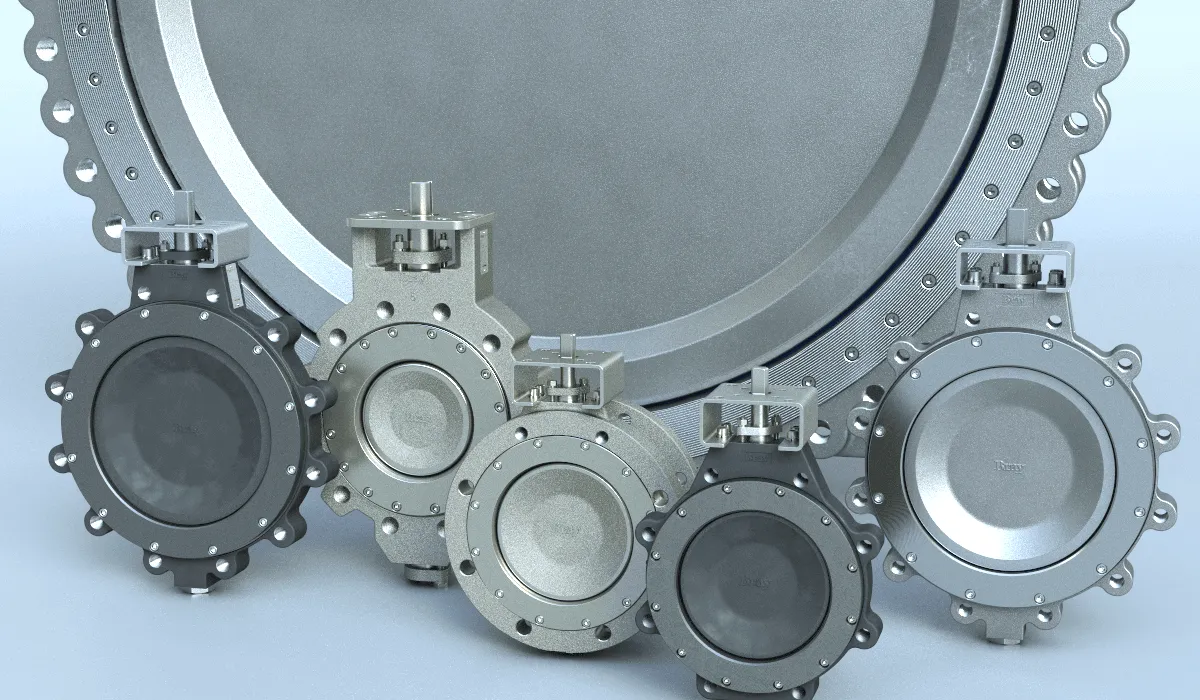

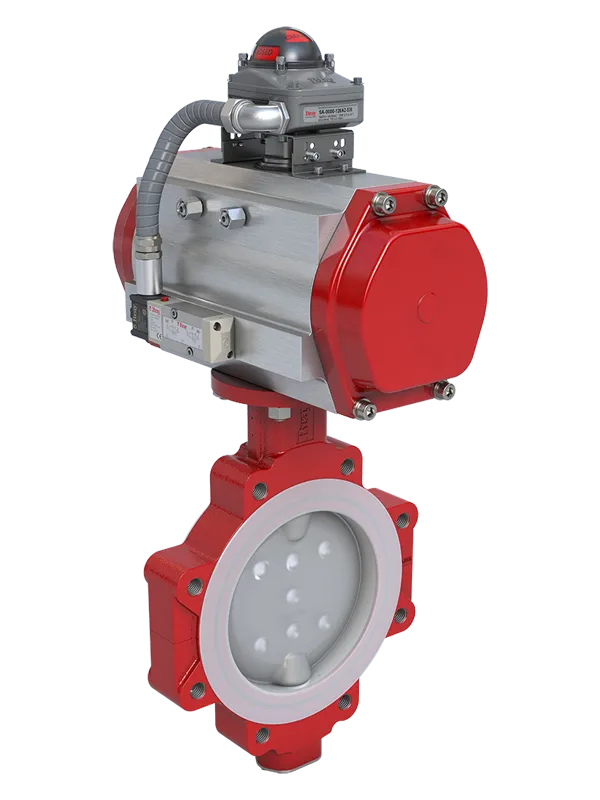

Améliorer la fiabilité des vannes - Sélection de robinets à tournant sphérique et vannes papillon

Dimensionnement de vanne de régulation en direct - Utiliser le programme de dimensionnement

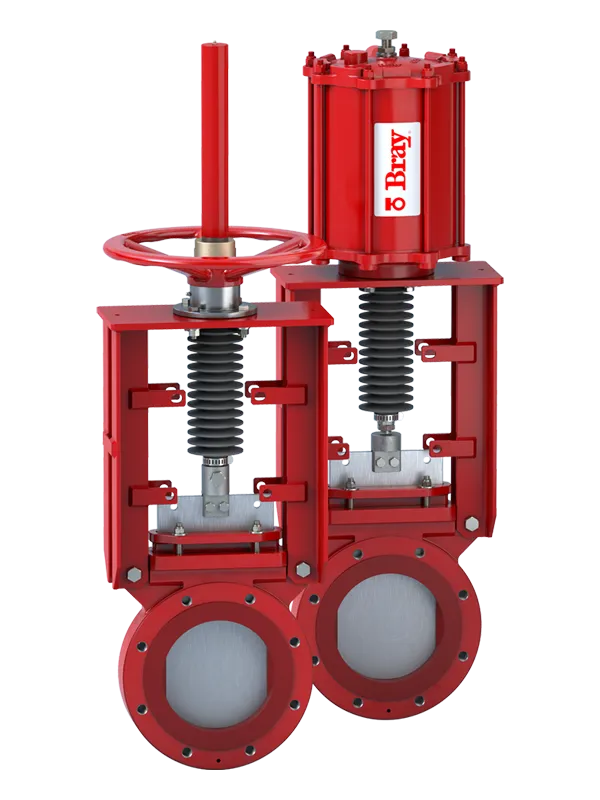

Siège remplaçable et étanchéité non affectés par les vibrations du processus

Amélioration de la fiabilité des vannes d'arrêt durgence à action rapide

Le robinet à tournant sphérique M1 pour conditions difficiles prolonge la durée de vie de 4 ans une application d'isolement autoclave HPAL

-copy.webp)

-copy.webp)

.webp)