The same valve is compatible with most world flange standards – ASME Class 125/150, BS 10 Tables D and E, BS 4504 NP 10/16, AS 2129 and JIS10. Additionally, Series 3A and 3AH valves are designed to comply with ISO 5752-Table 2 (EN558 Table 13) face-to-face and ISO 5211 actuator mounting flanges resulting in one valve design that can be used in a variety of world markets.

More Details

Features & Benefits

-

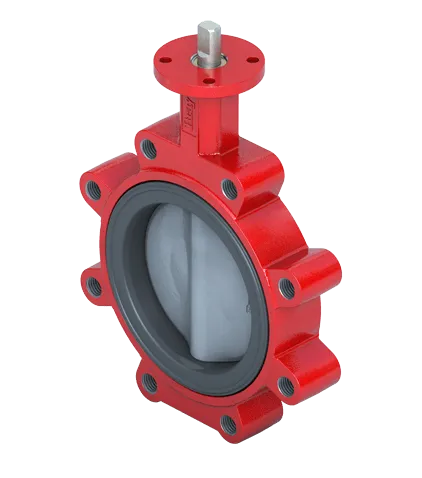

A. Stem

Precision double "D" disc to stem connection drives the disc without the need of screws or pins.

-

B. Seat

Bray's bonded seat design lowers torque and provides complete isolation of flowing media from the body. The seat also features a molded O-ring which eliminates the use of flange gaskets.

-

C. Stem Retaining Assembly

The stem is retained in the body by means of a unique Stainless Steel Spirolox® retaining ring, a thrust washer and two C-rings, manufactured from brass as standard, stainless steel upon request. The retaining ring may be easily removed with a standard hand tool. The stem retaining assembly prevents unintentional removal of the stem during field service.

-

D. Stem Bushing

Non-corrosive, heavy duty acetal bushing absorbs actuator side thrusts.

-

E. Stem Seal

Double "U" cup seal design is self-adjusting, gives positive sealing in both directions, and prevents external substances from entering the stem bore.

-

F. Extended Neck

Extended neck length allows for 2" (50 mm) of piping insulation and is easily accessible for mounting actuators.

-

G. Primary & Secondary Seals

These seals prevent line media from coming in contact with the stem or body. Primary Seal is achieved by an interference fit of the molded seat flat with the disc hub. Secondary Seal is created because the stem diameter is greater than the diameter of the seat stem hole.

-

H. Disc

Spherically machined and hand polished to provide a bubble-tight shutoff, minimum torque, and longer seat life.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business