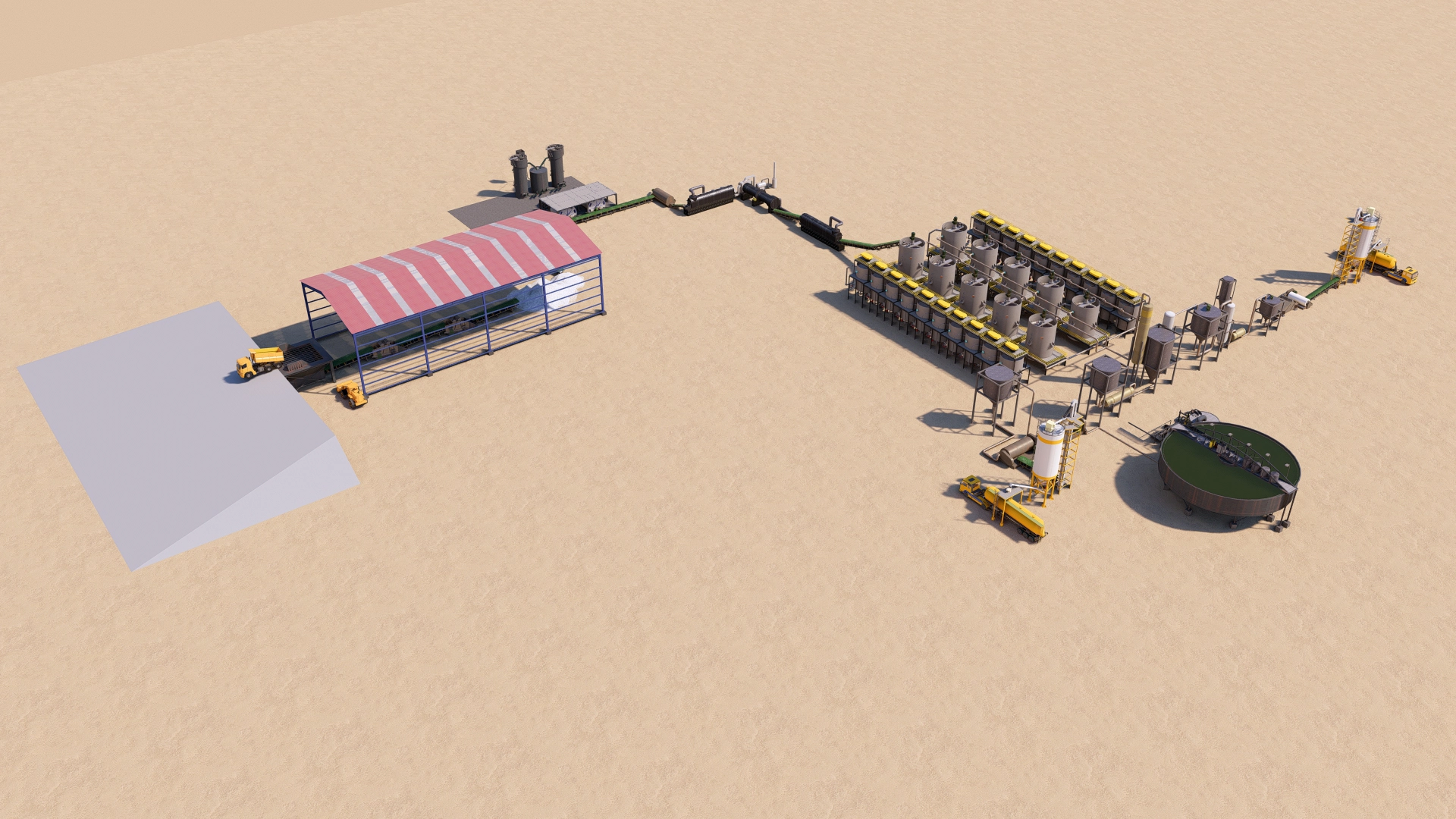

Soluções para a indústria de mineração de lítio

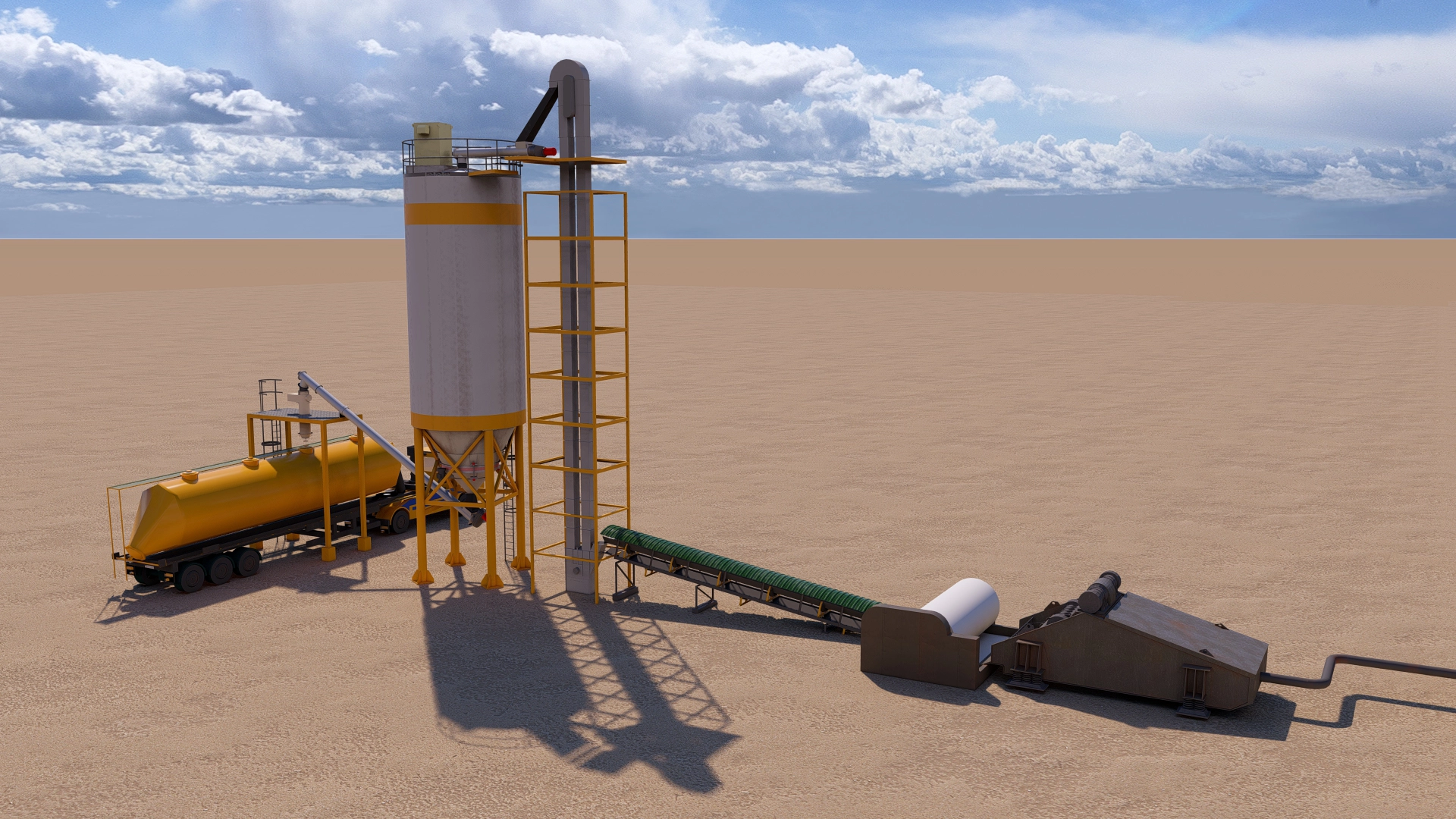

Circuito de moagem

Leitos fluidizados e calcinadores

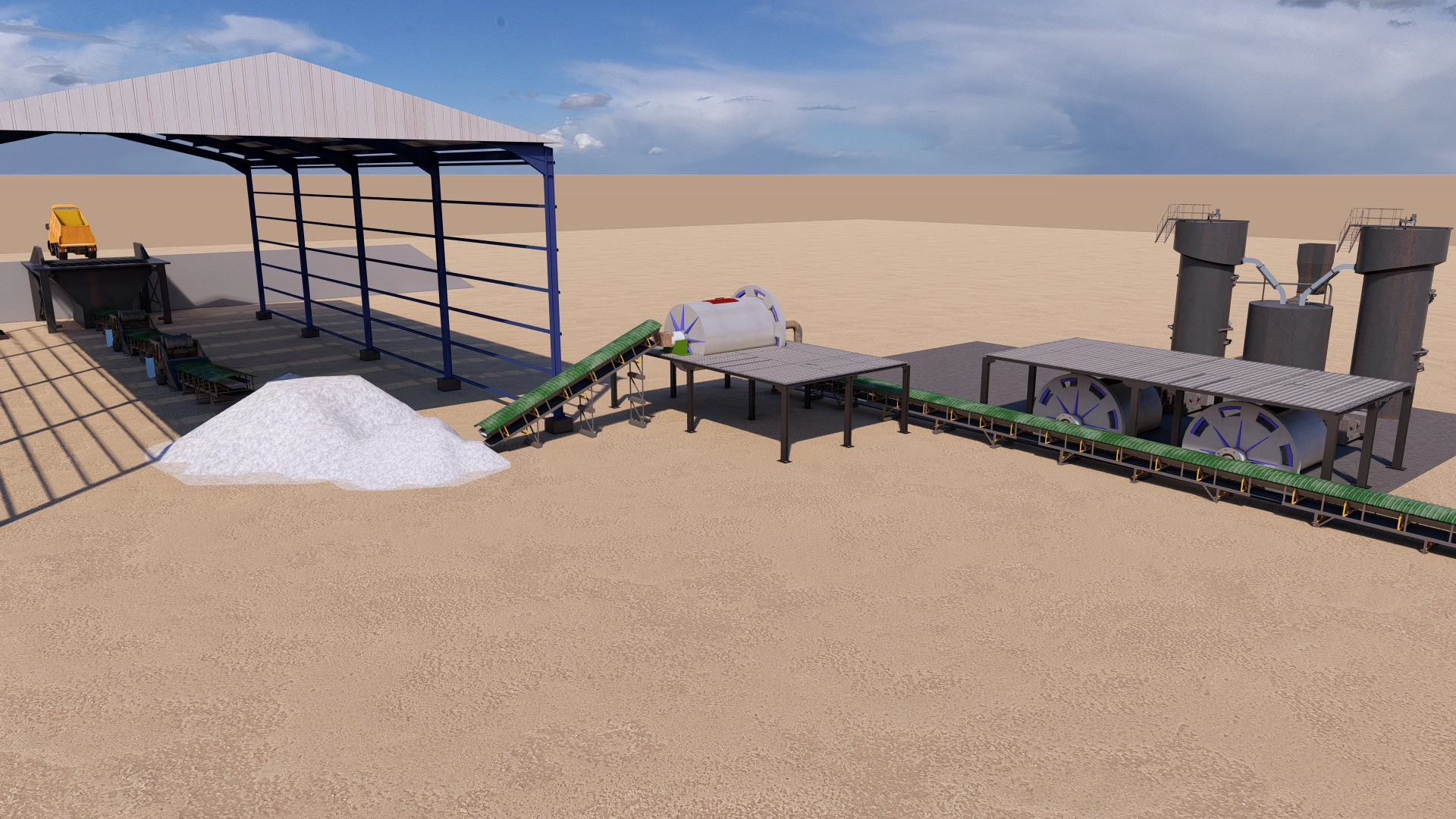

Lixiviação/flutuação

Evaporação e cristalização

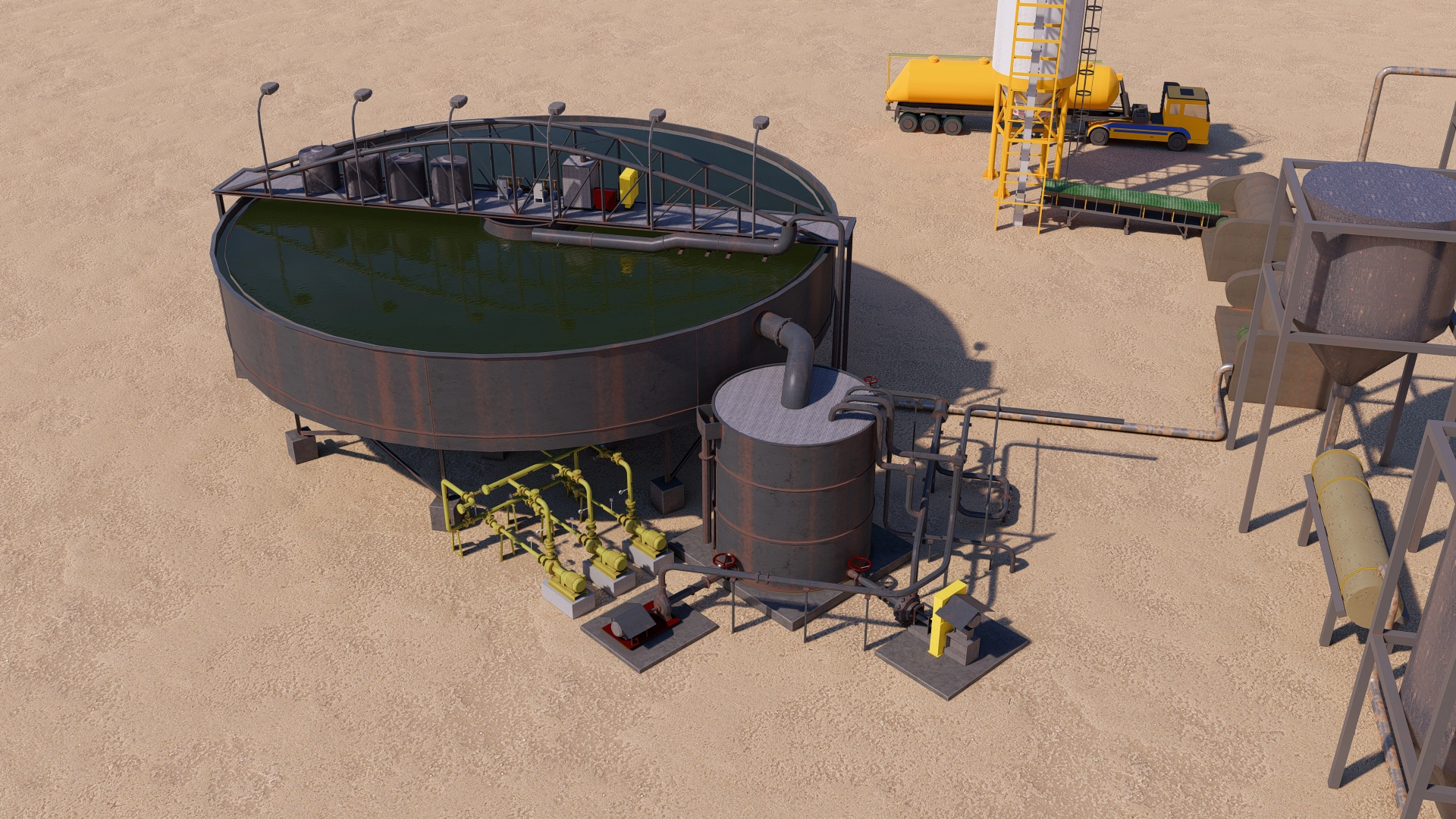

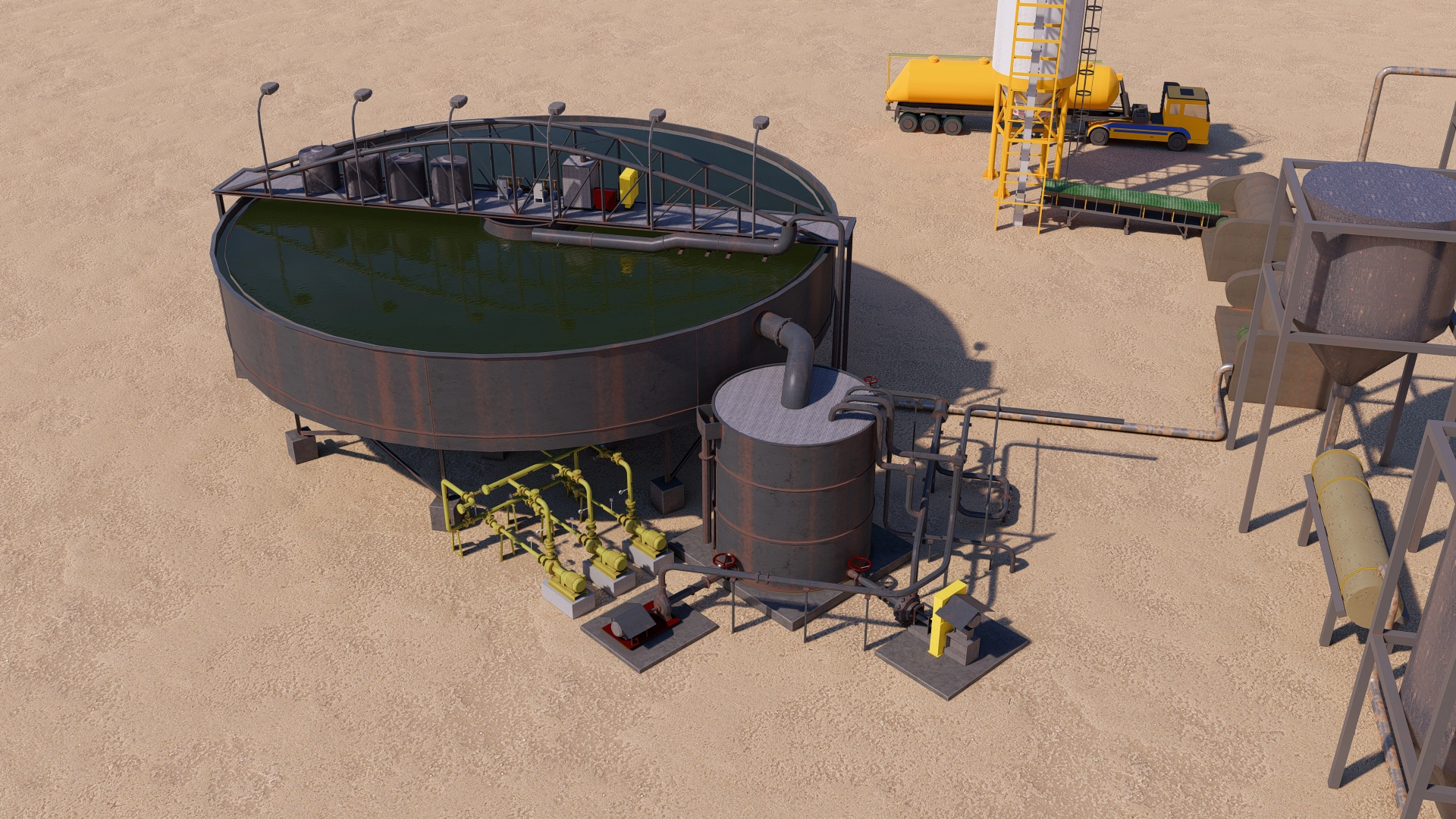

Espessamento

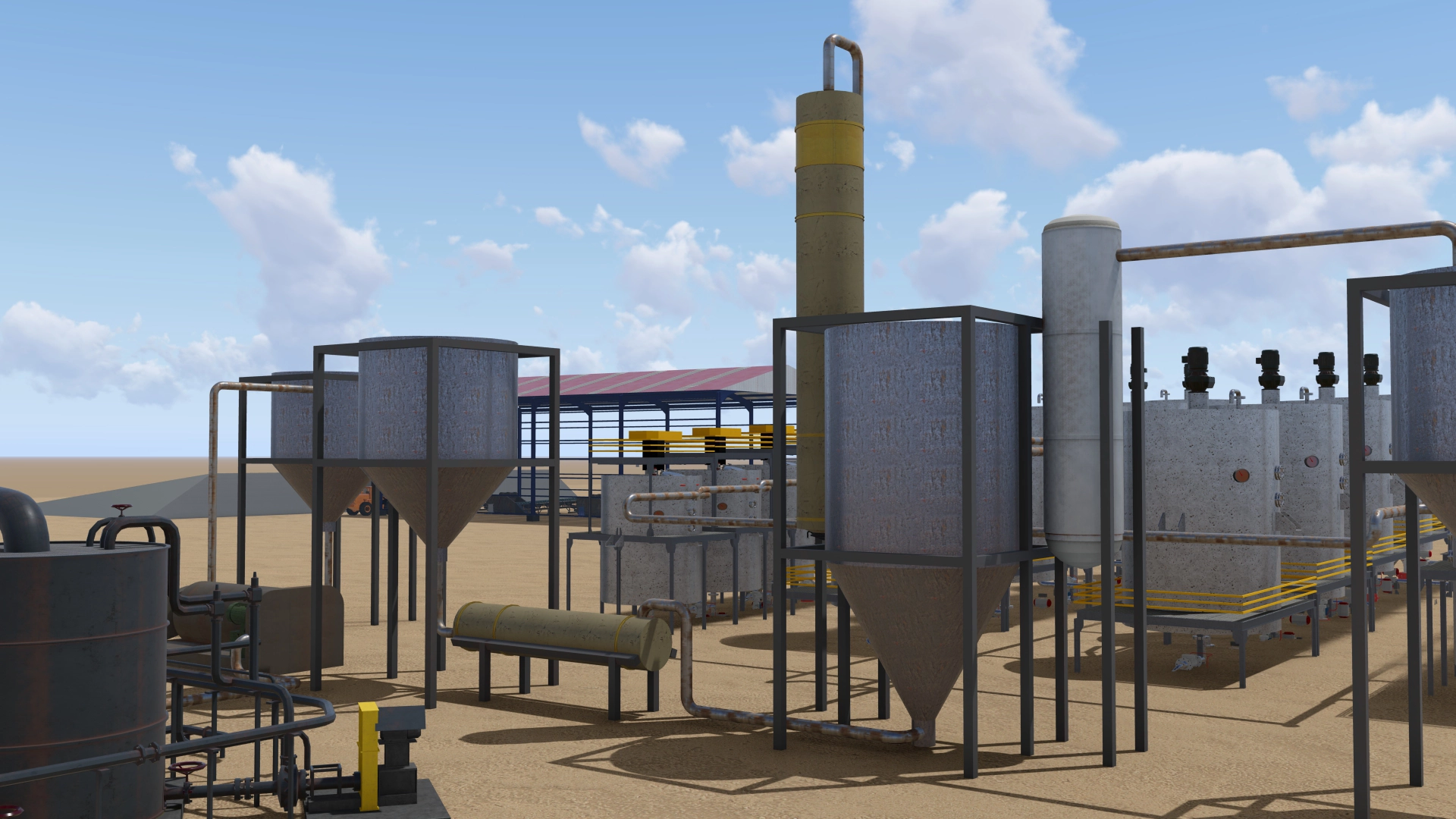

Tanques de recuperação de lítio

Filtragem e secagem

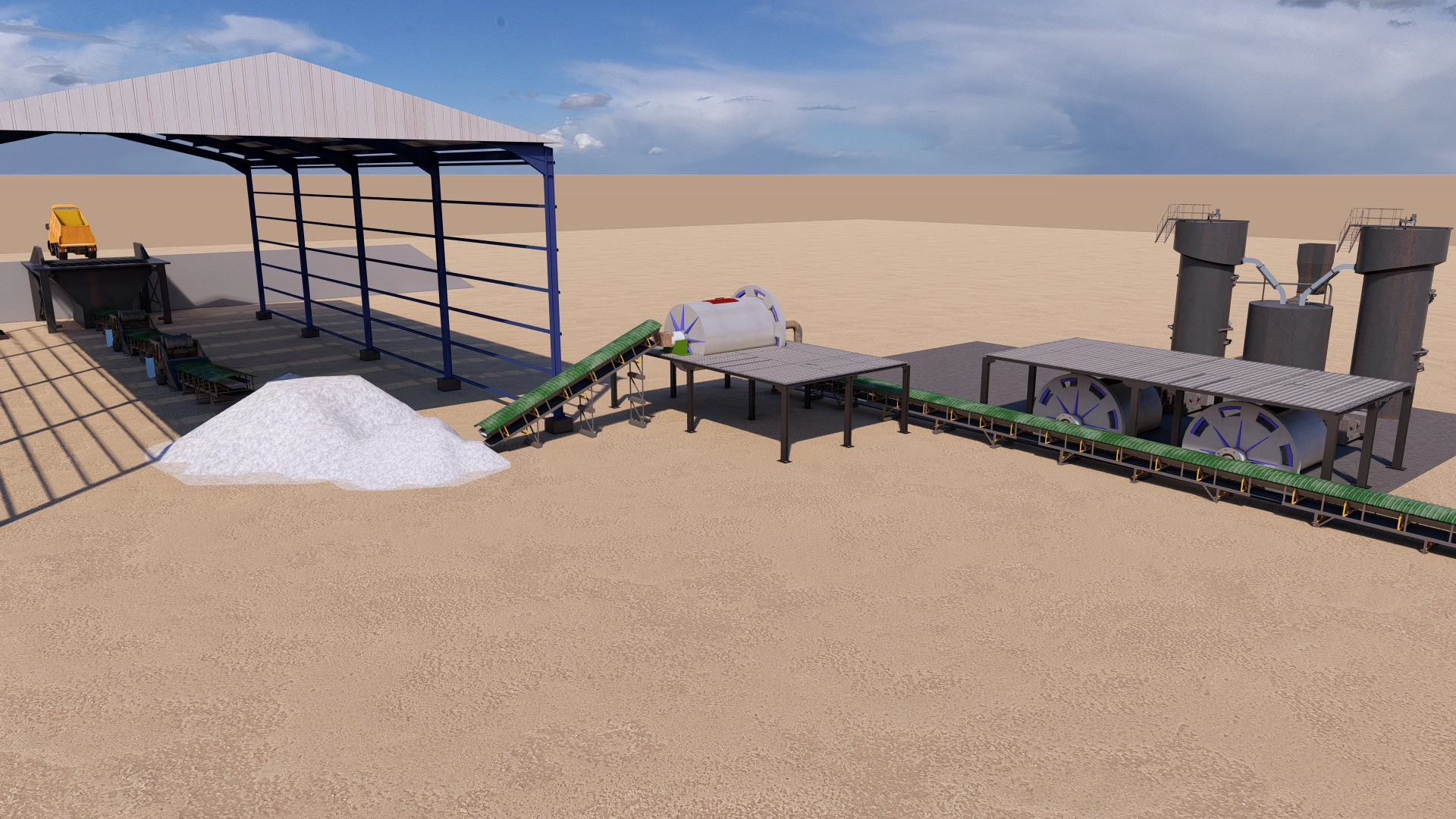

Circuito de moagem

O minério de espodumênio é triturado e moído até atingir um tamanho menor para ser preparado. Os reagentes de hidrita e dualamita são moídos e adicionados ao processo.

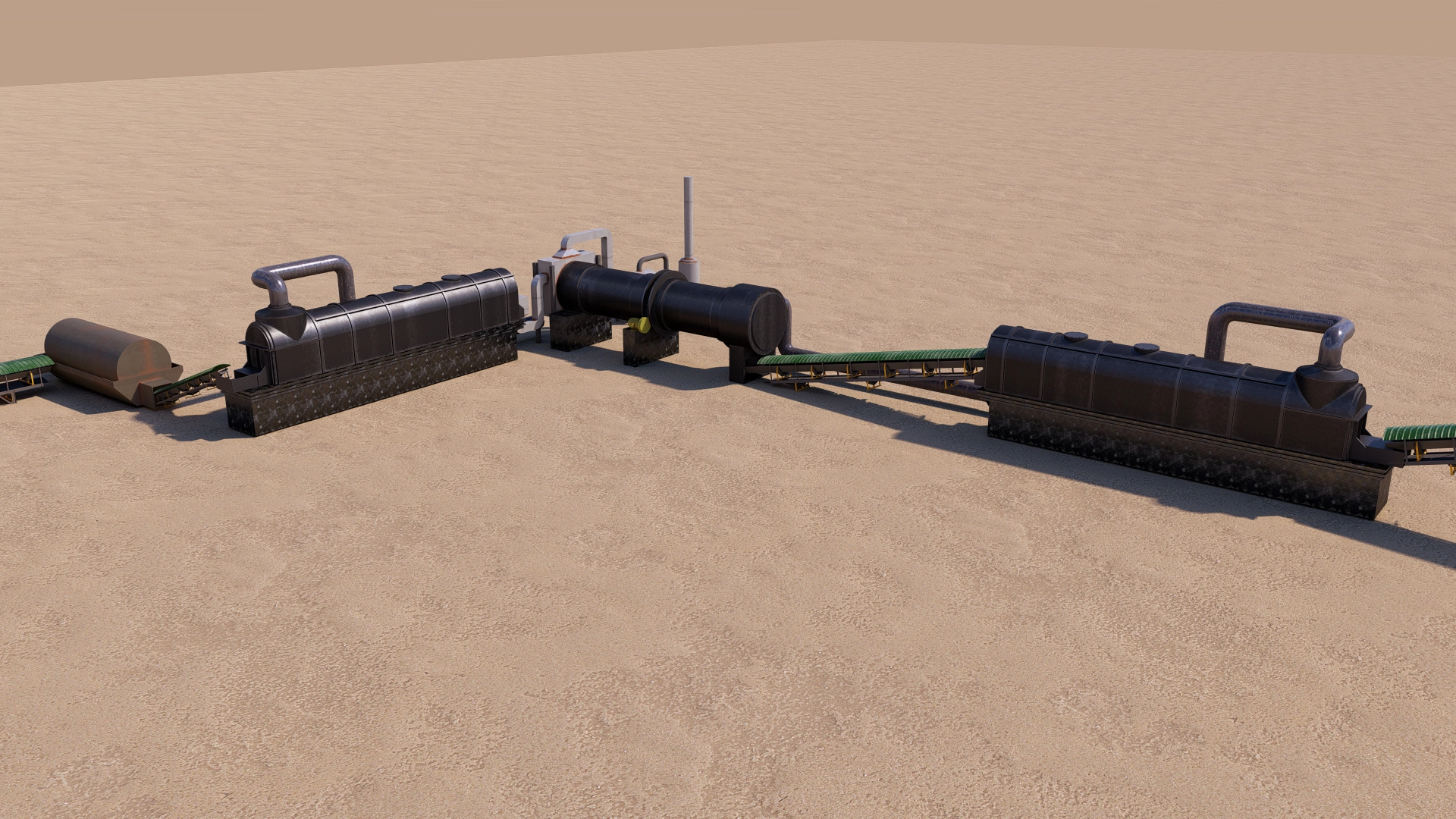

Leitos fluidizados e calcinadores

Lítio, sódio e potássio são convertidos em solvatos solúveis em água a 1000 °C e, em seguida, resfriados a ar no calcinador.

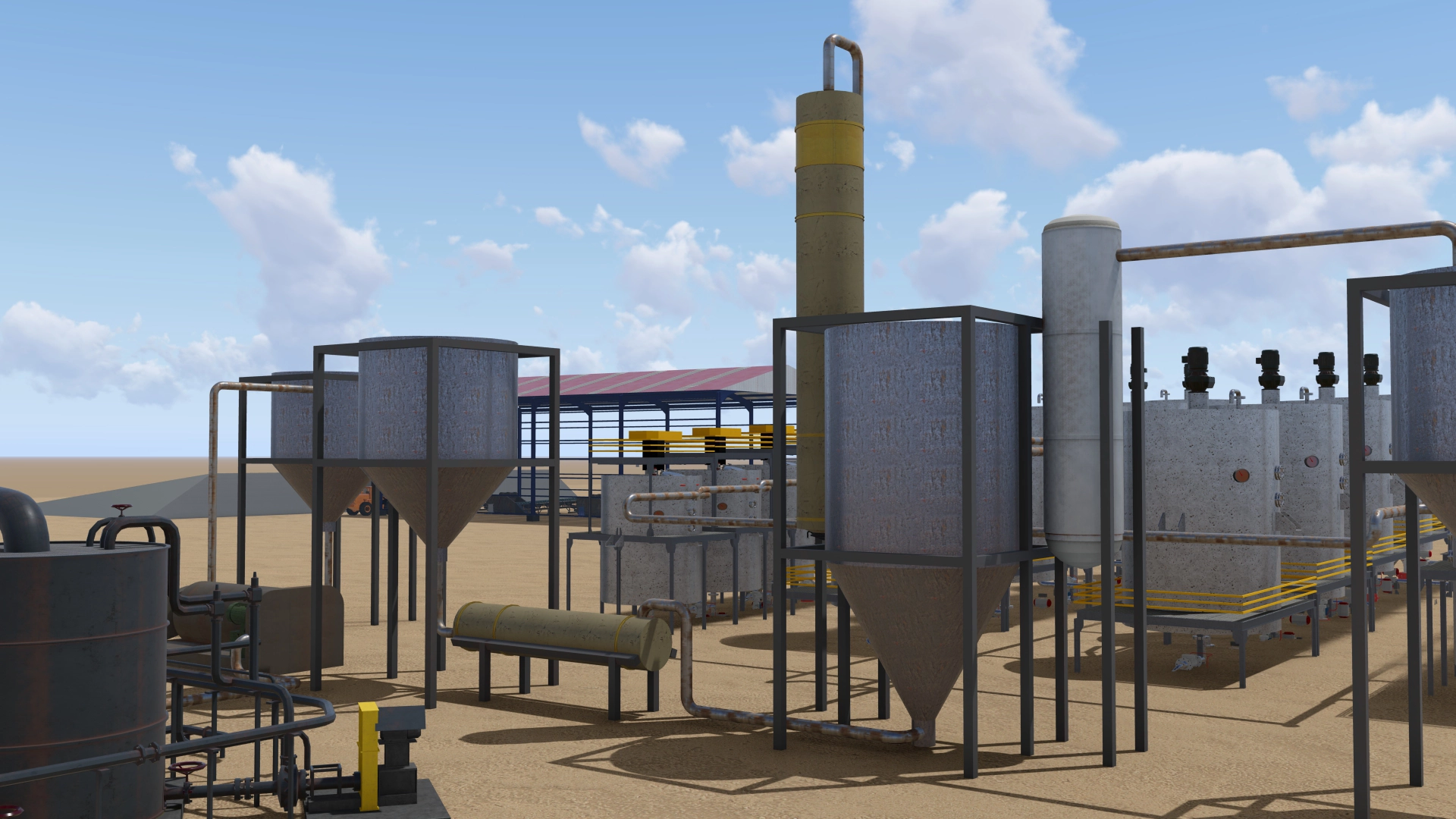

Lixiviação/flutuação

Dissolvido junto a traços de magnésio e cálcio. Outras impurezas permanecem insolúveis. A solução de lixiviação é reciclada para maximizar a concentração de lítio.

Evaporação e cristalização

A solução de lixiviação clarificada é misturada com as soluções recicladas e enviada aos evaporadores, e o sulfato de lítio fica ainda mais concentrado.

Espessamento

Concentra a lama ao remover o excesso de água usando a gravidade para concentrar sólidos finos, otimizando a densidade da lama para a filtragem a jusante como sulfato de potássio.

Tanques de recuperação de lítio

O cálcio e o magnésio são removidos do concentrado e, em seguida, o carbonato de lítio é precipitado ao adicionar o carbonato de sódio.

Filtragem e secagem

Filtra o subproduto (Sal de Glauber) e o carbonato de lítio após a recuperação do lítio ou o sulfato de potássio do espessamento, lava e seca para ensacar.

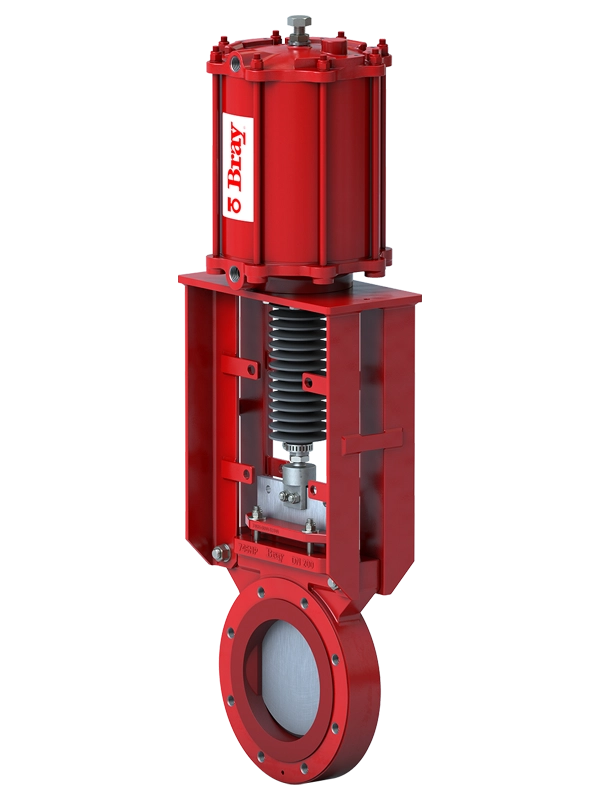

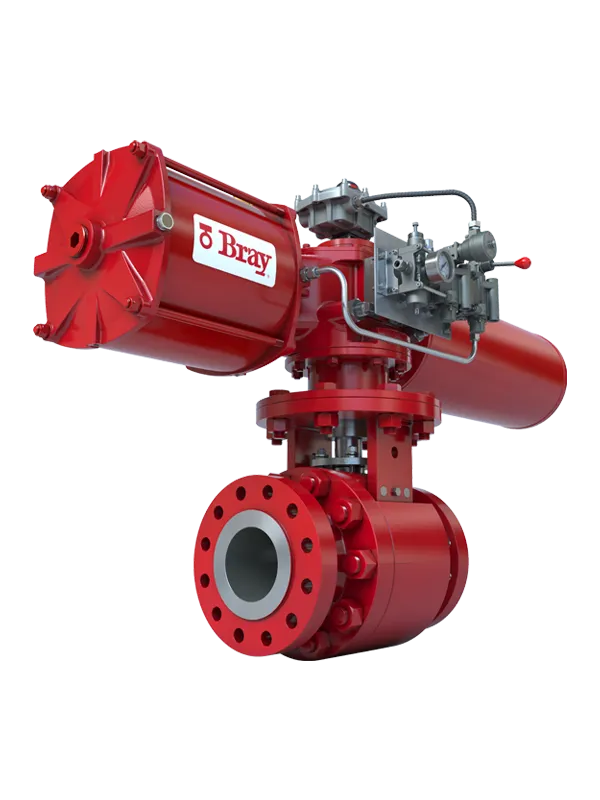

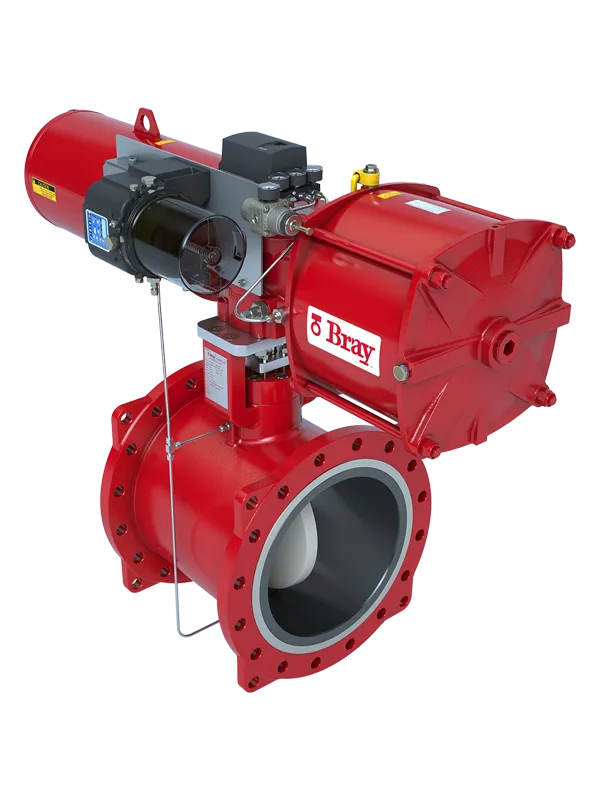

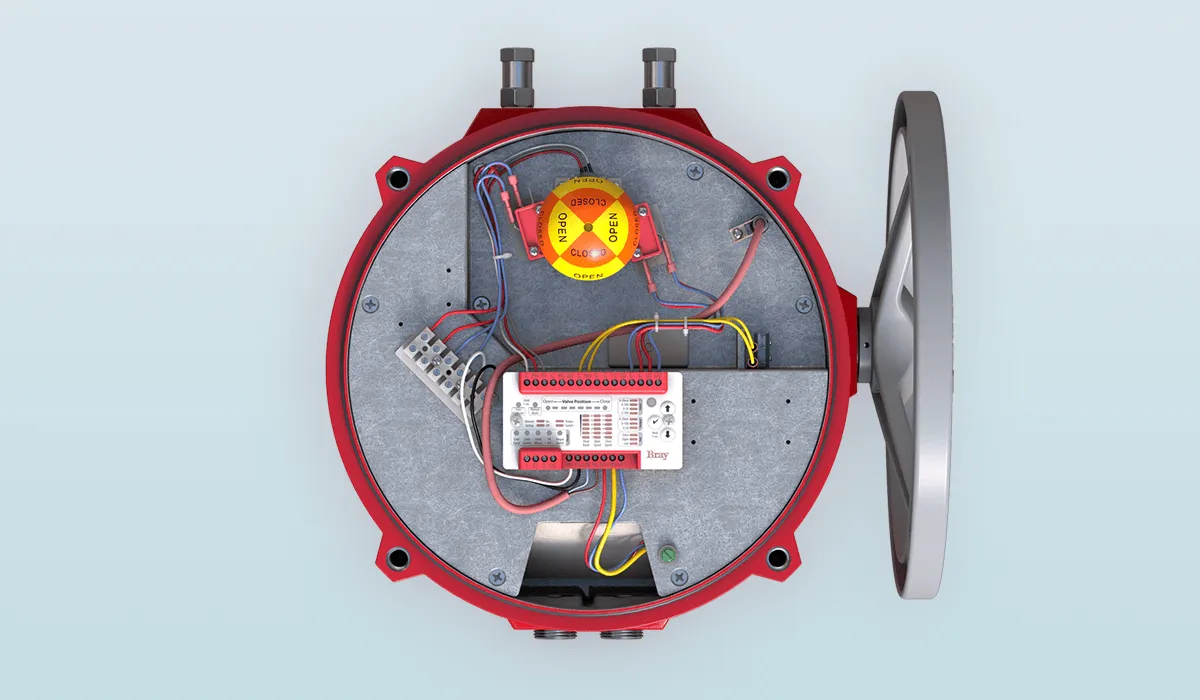

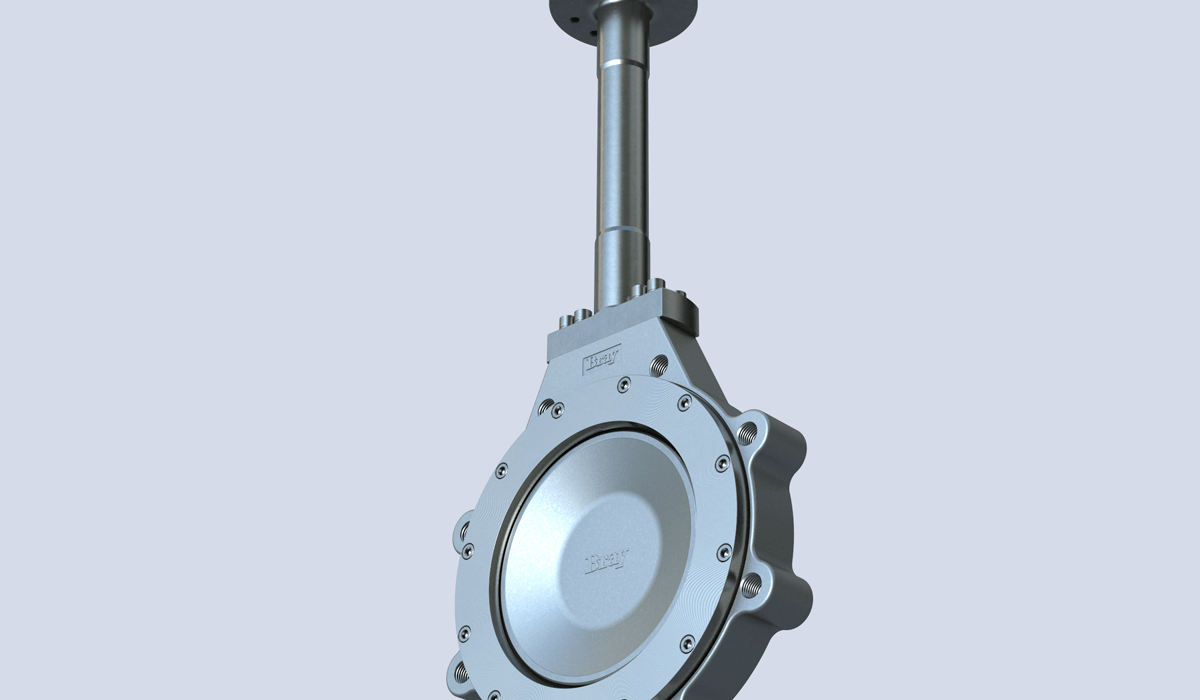

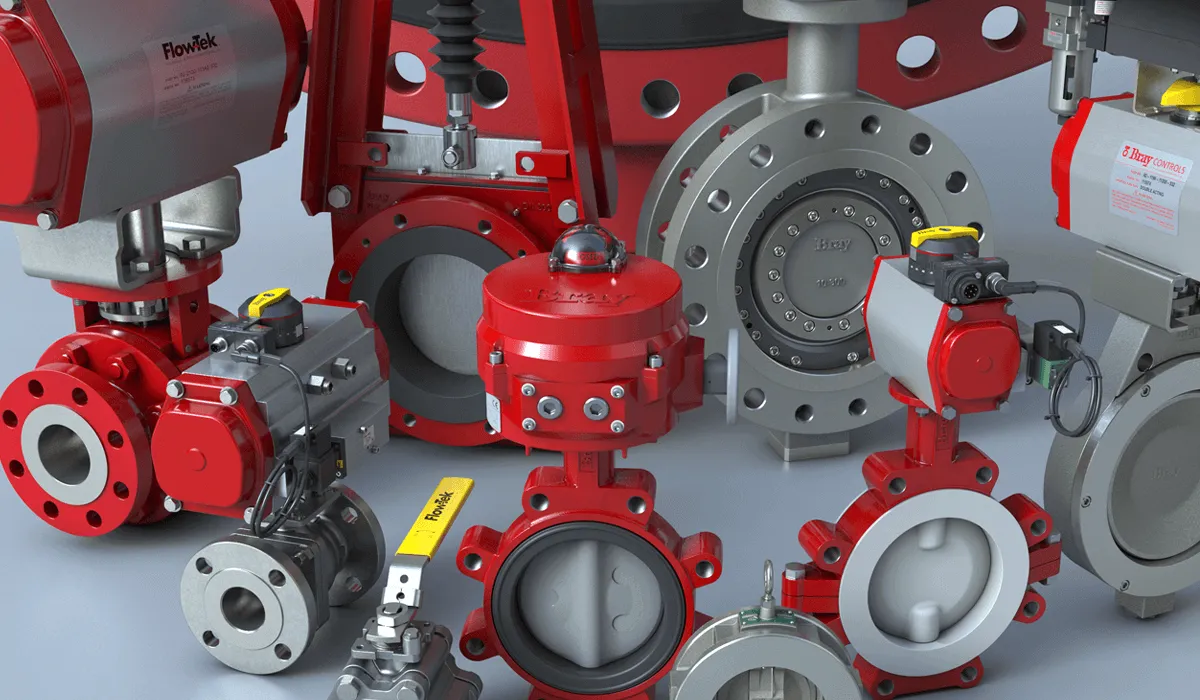

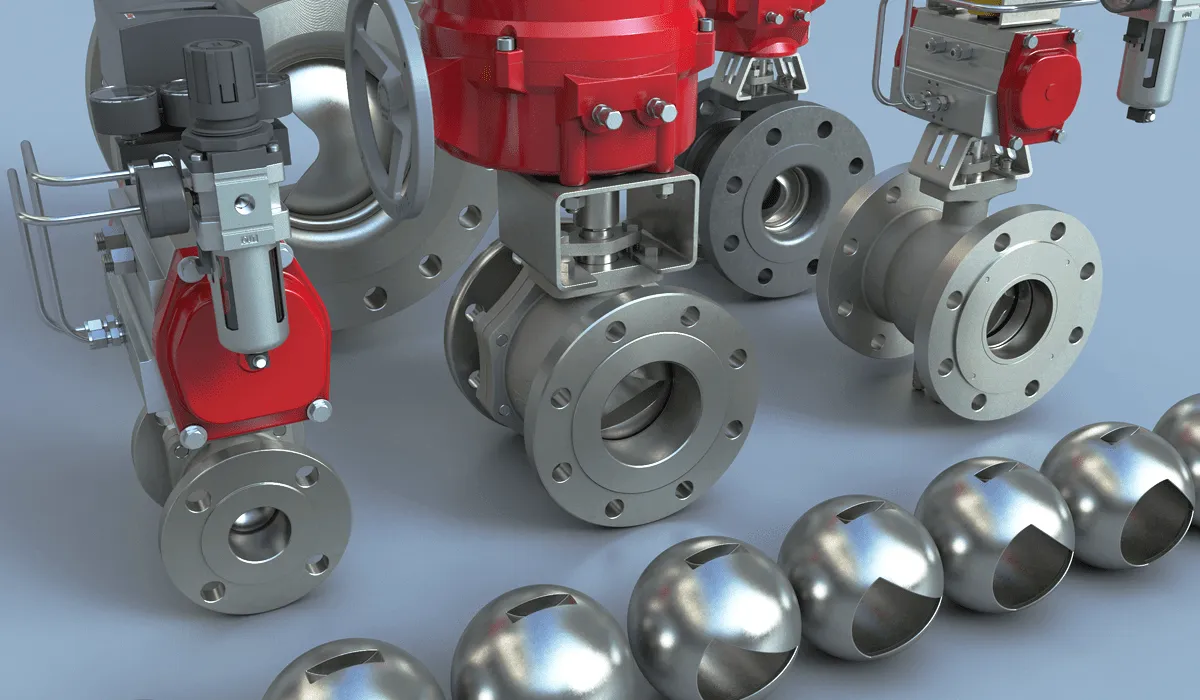

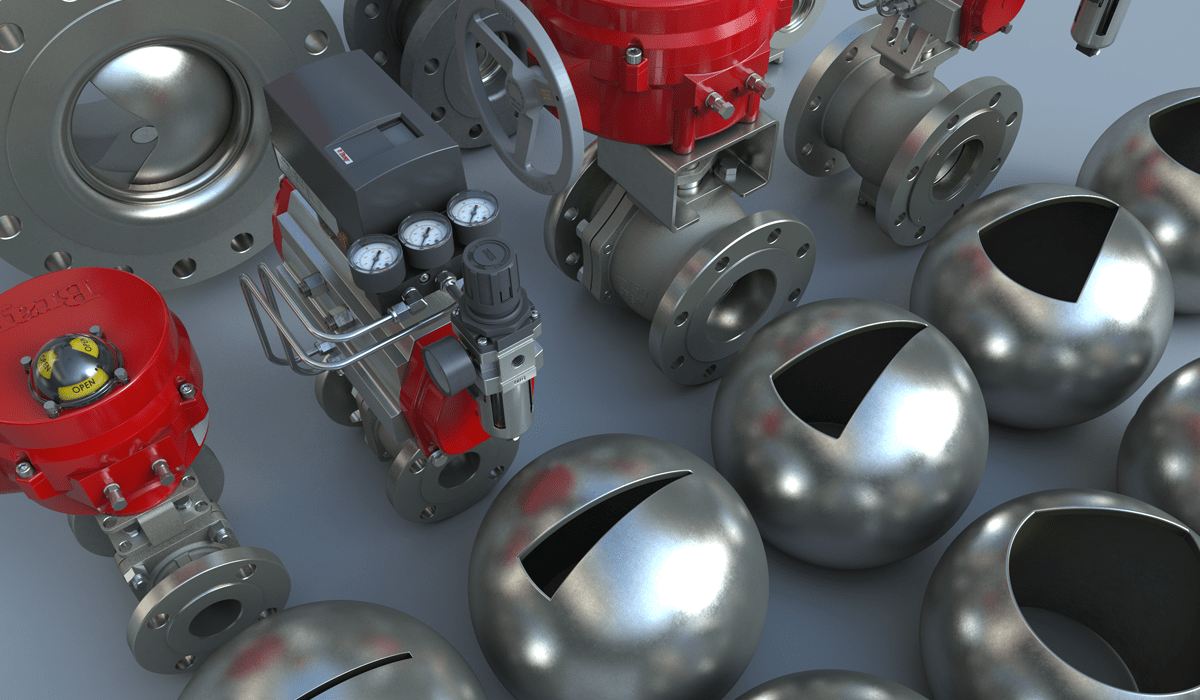

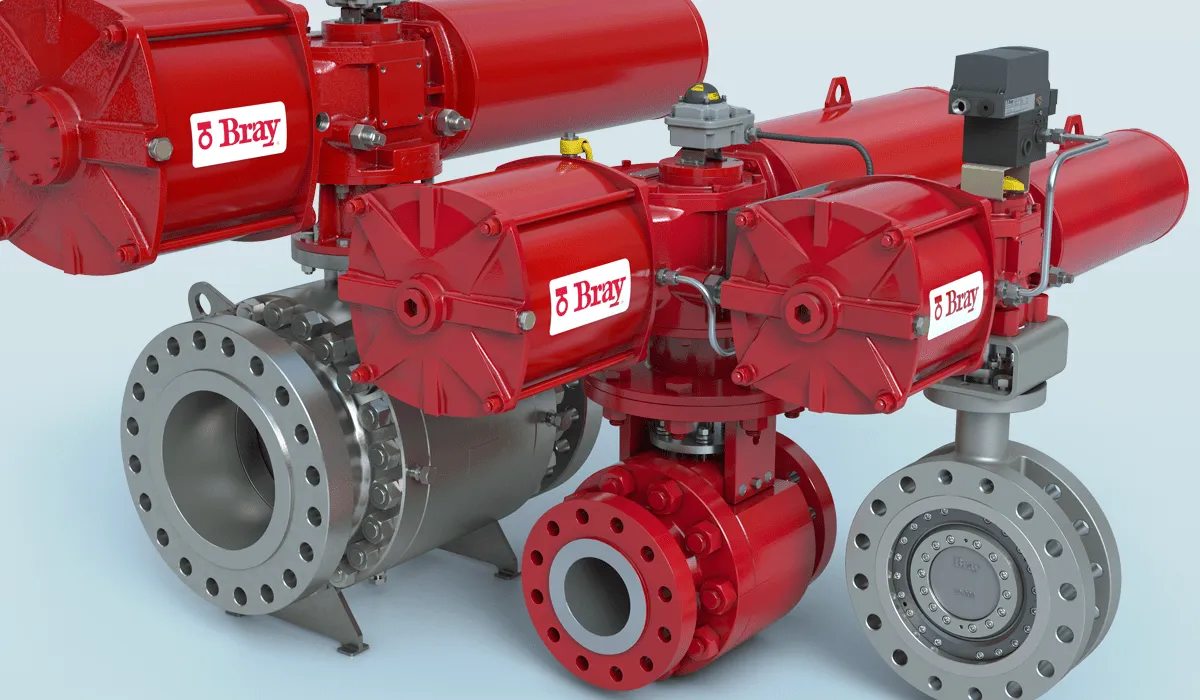

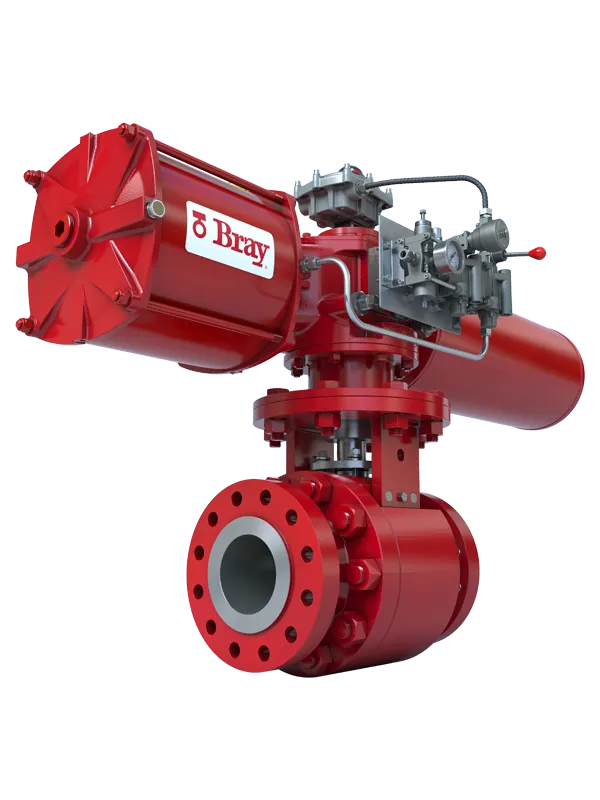

Melhoria da confiabilidade da válvula – Seleção de válvulas de esfera de serviço severo

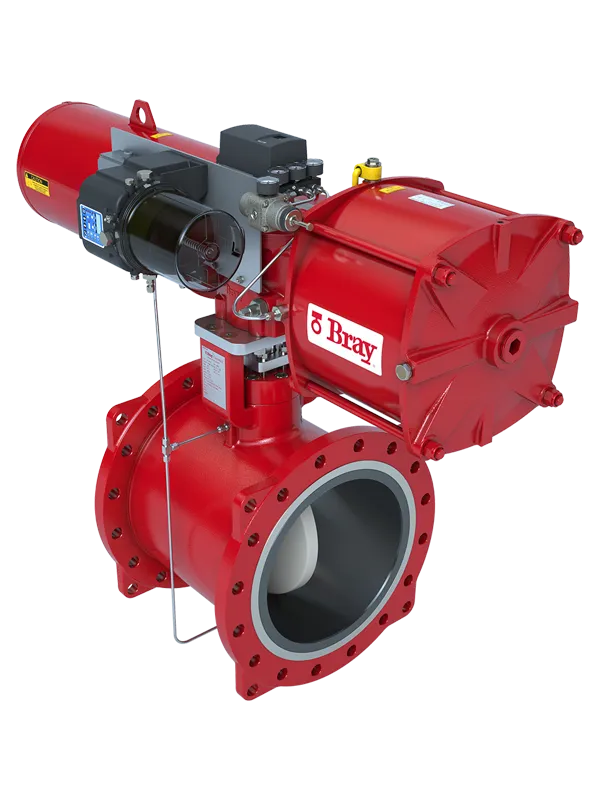

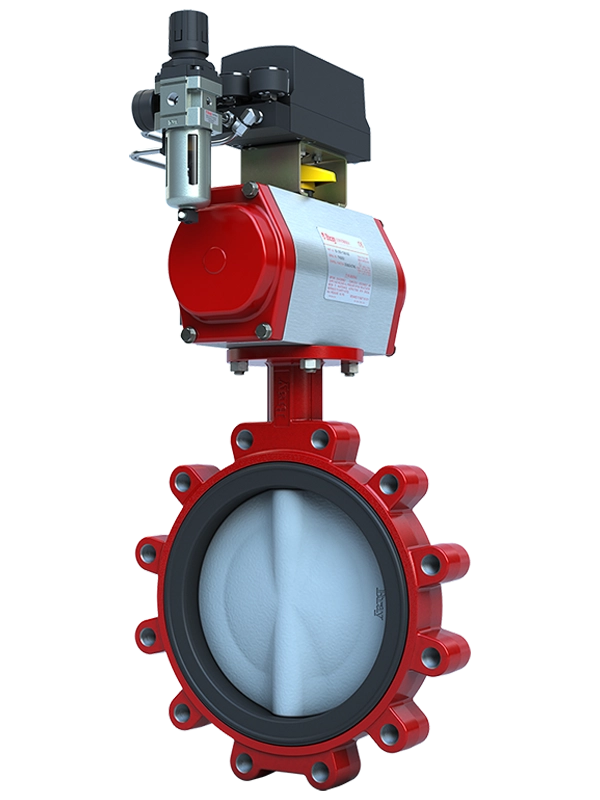

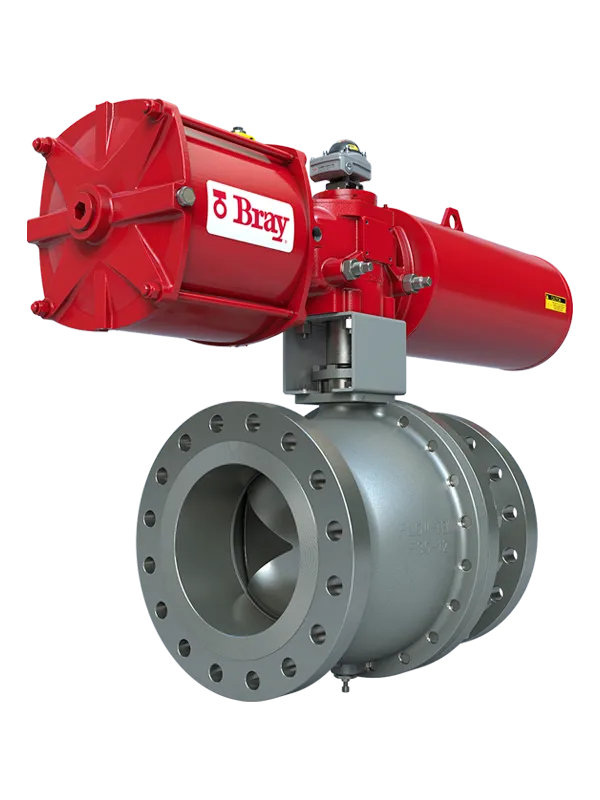

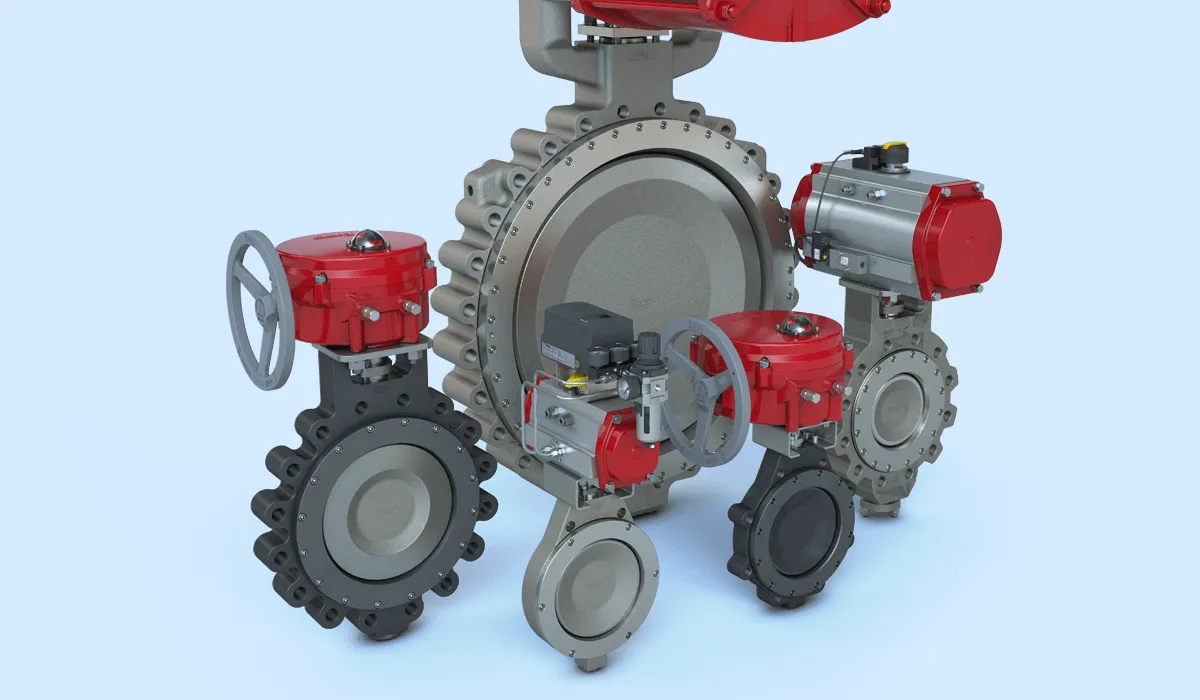

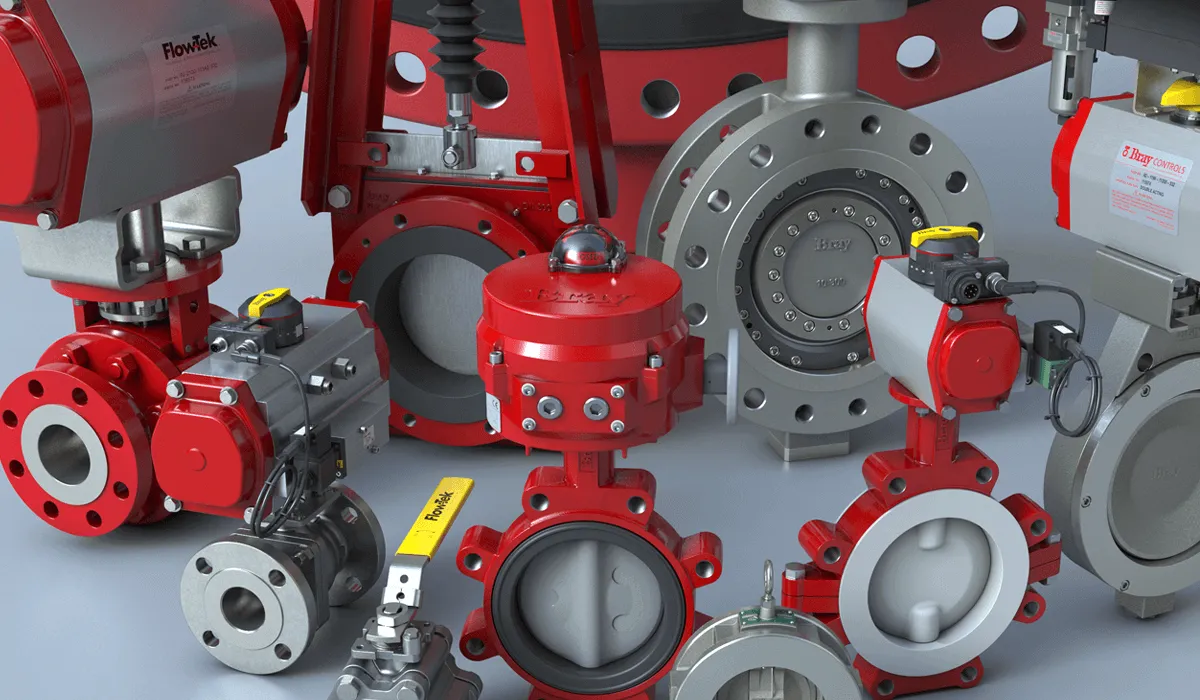

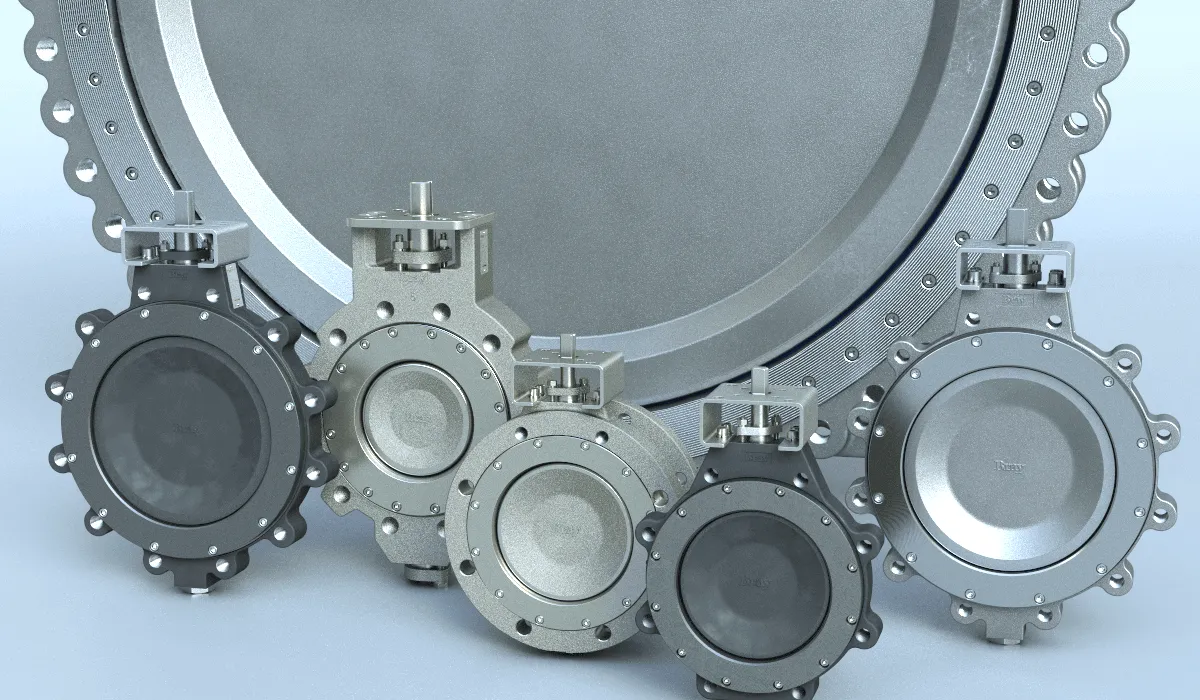

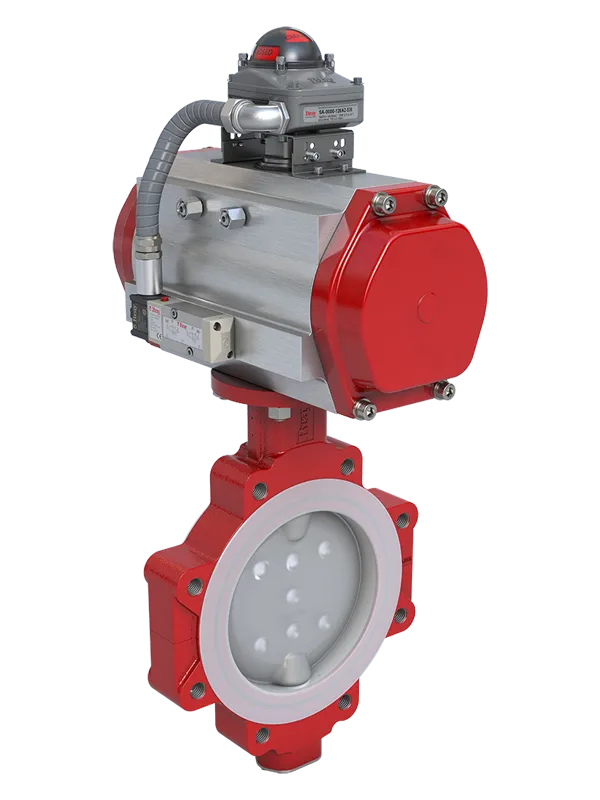

Melhoria da confiabilidade da válvula – Seleção de válvulas borboleta e de esfera

Vantagens das válvulas de controle de um quarto de volta para controle de modulação

Dimensionamento ao vivo de válvula de controle – uso do programa de dimensionamento

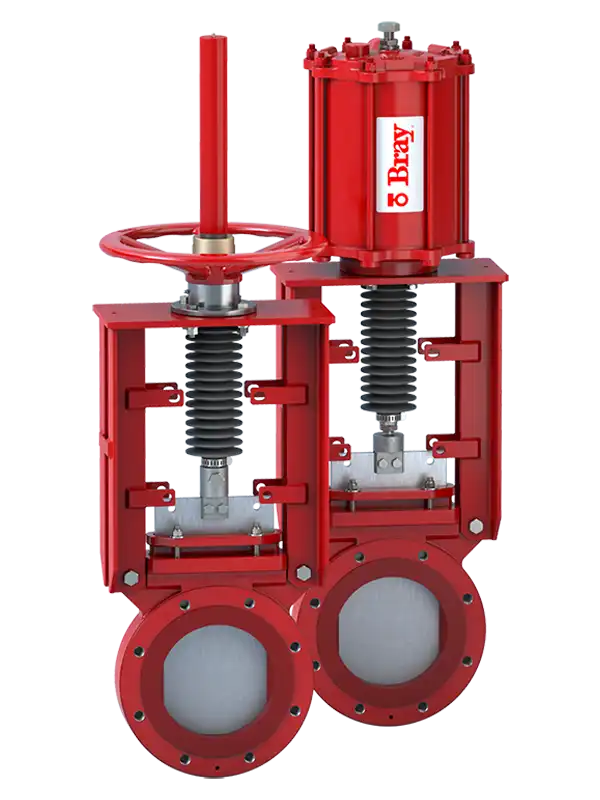

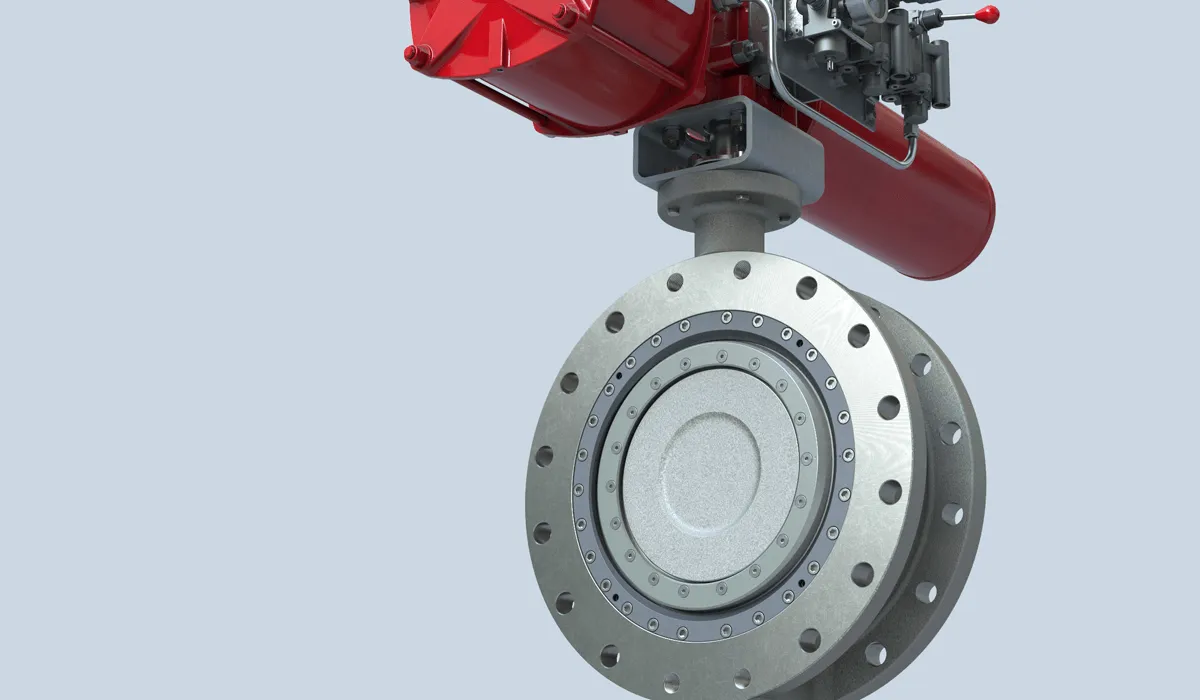

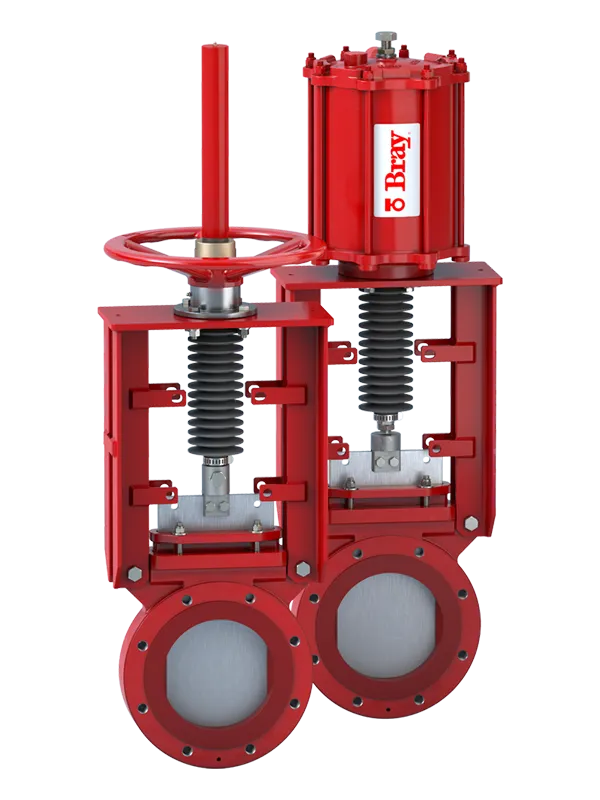

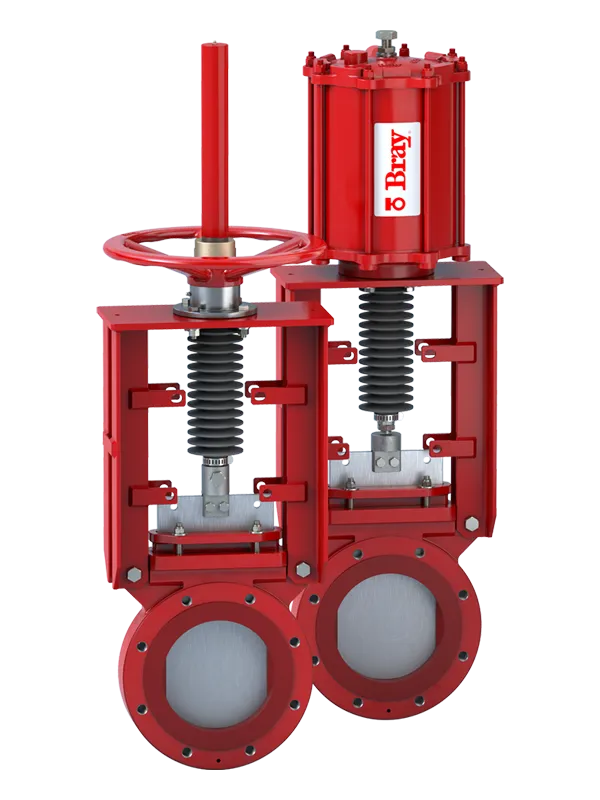

Melhoria da confiabilidade de válvulas de desligamento de emergência de ação rápida

A válvula esfera para serviço severo M1 prolonga a vida útil por 4 anos em isolamento de autoclave HPAL

-copy.webp)

-copy.webp)

.webp)