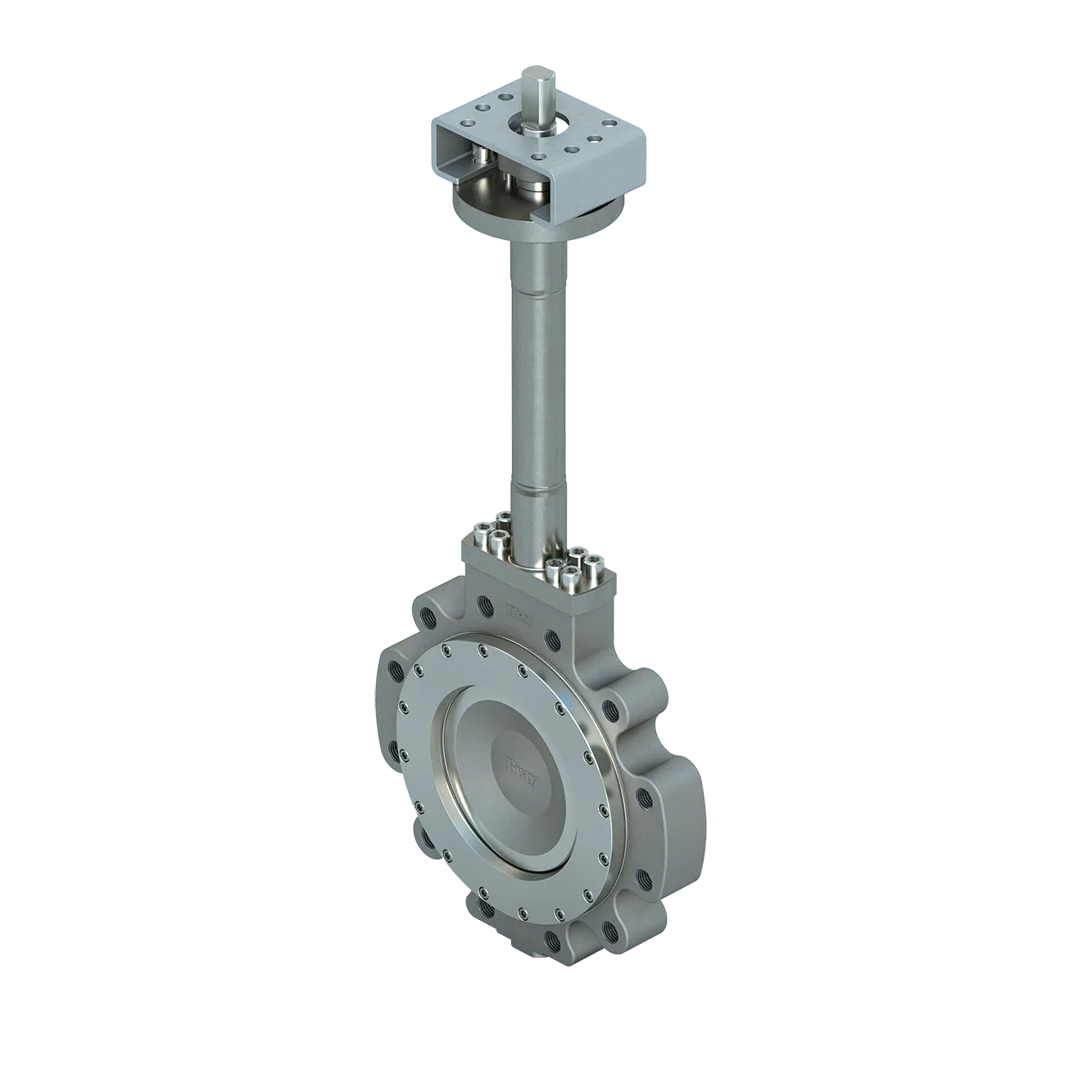

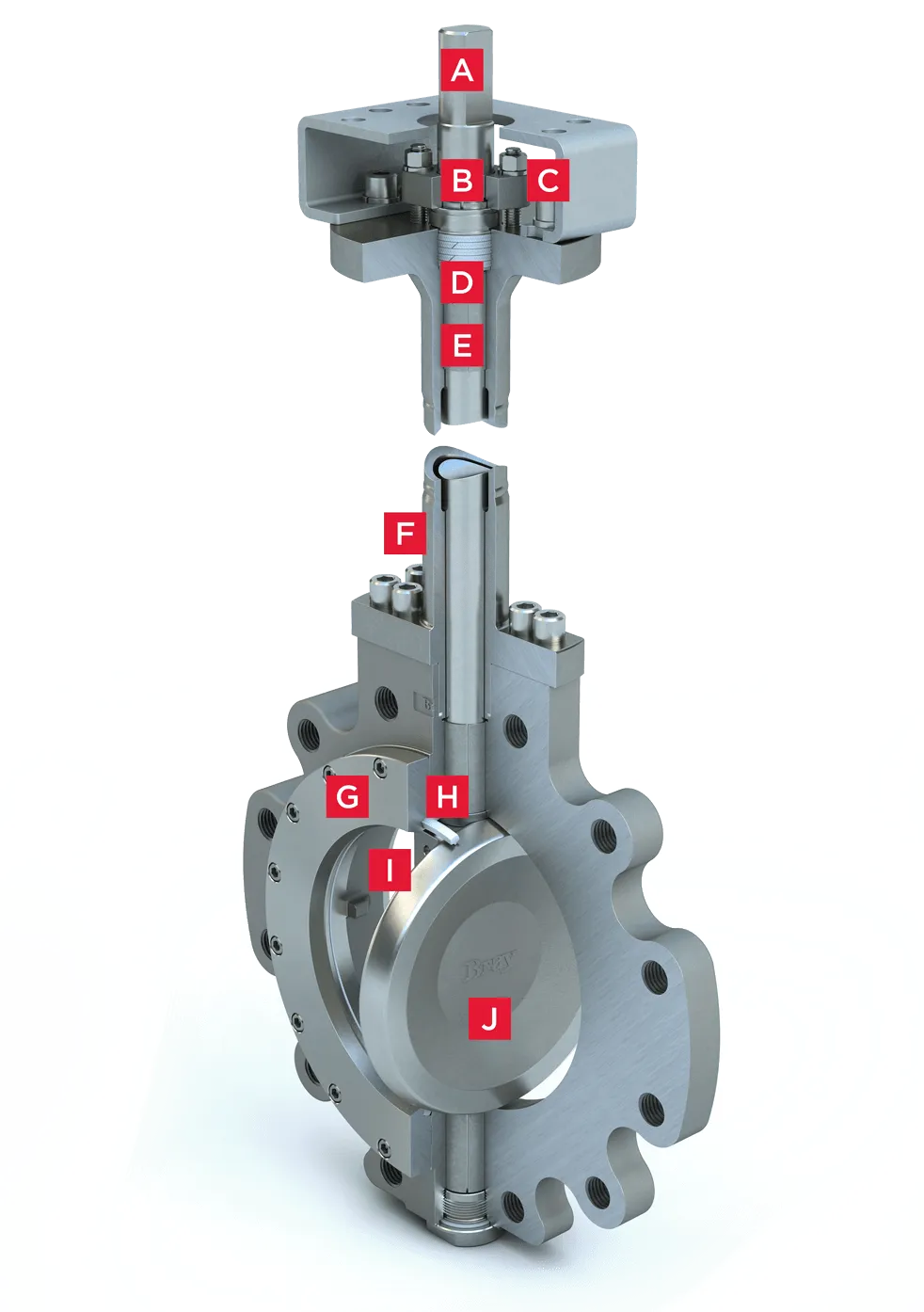

Raising the Performance Bar

The McCannalok™ Cryogenic high performance butterfly valve provides industry leading cryogenic sealing technology and performance while being produced to the highest quality standards. The valve is designed to handle the most difficult medias in today’s

industrial environments — liquid oxygen, liquid natural gas, and other cryogenic liquids.

Cryogenic Testing

Bray operates world class cryogenic testing facilities in the USA, China, and India dedicated for research & development validation and customer specific testing. Run by trained and experienced cryogenic valve specialists, our Raymond Technical Center in Houston utilizes:

- Cryogenic test pit for safe testing of large valves.

- 6,000-gallon liquid nitrogen tank.

- Mass spectrometers.

Precision Cleaning

Bray operates three precision cleaning facilities around the world to meet customer's oxygen cleaning needs.