Quality is everything our customers experience. It's integrated into every aspect of the Bray culture, making us World Class in our industry. We deliver Quality at Every Step, amplifying product reliability and customer satisfaction. Quality is a differentiator for Bray, driving our reputation for excellence globally.

概述

Bray’s Culture of Quality

Bray Operational Value Chain

“Quality comes not from inspection, but from improvement of the production process.”

— W. Edwards Deming

Upstream: Raw materials, castings, forgings, machined

parts, molded parts, motors, electronics, and finished assemblies.Bray International: Quality control, warehousing, manufacturing,

assembly, and shipping.

Downstream: 3rd party distribution, EPCs, and end users.

Bray Management System

Our management system is centrally managed, globally deployed, and locally customized. We use common procedures and work instructions across divisions, translated into local languages. Our system is cross-site audited and thoroughly vetted by notified bodies, certifying bodies, and customers over nearly 40 years.

Source Quality: Verification of conformance early and often, traceable

materials, electronic records, transparency to source vendors, and

third-party certified products.

Product Quality Planning: Risk-based approach with control plans

ensuring consistent quality.

Continuous Improvement: Define, measure, analyze, improve, and

control.

Advanced Product Quality Planning

Control plans

Failure Modes & Effects Analysis

(Design & Process)

Process capability studies

Continuous improvement feedback loops

Verification & Traceability

- Data and statistics-driven improvements

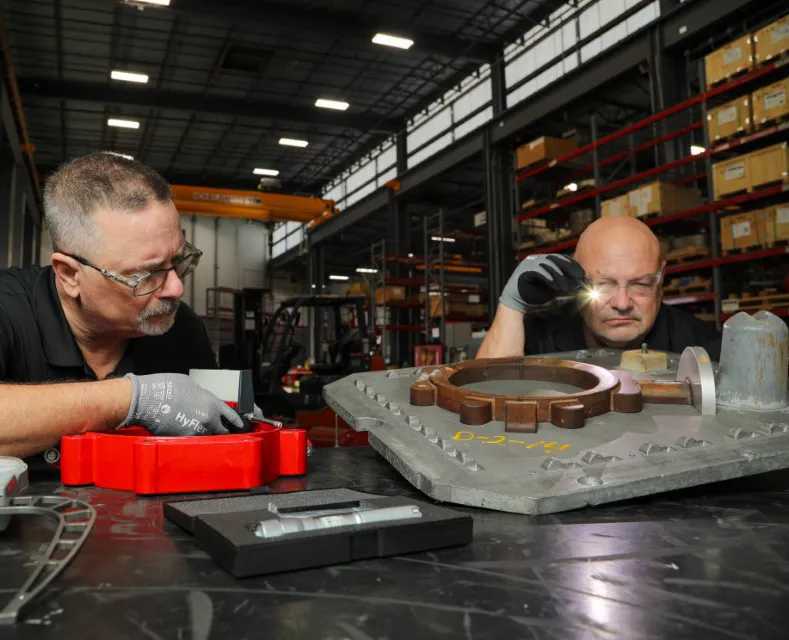

Modern inspection instruments

Traceability with test certificates

Segregated and labeled materials

Quarantine nonconformances

Material & Metrology Laboratories

Staffed with engineers

Positive material identification

Material strength and toughness testing

Optical spectrometry and comparators

Rheometer and instrument calibration

Globally standardized equipment

and programs

Third-party calibrated and certified

(within microns)